Last Updated on February 26, 2024

The manufacturing sector is the backbone of many economies, driving innovation, creating jobs, and contributing significantly to GDP. However, a persistent challenge faced by the industry is the skills gap, hindering its growth and potential. In this article, we delve into the intricacies of the skills gap manufacturing and explore how nearshore manufacturing in Mexico could be the key to addressing this pressing issue.

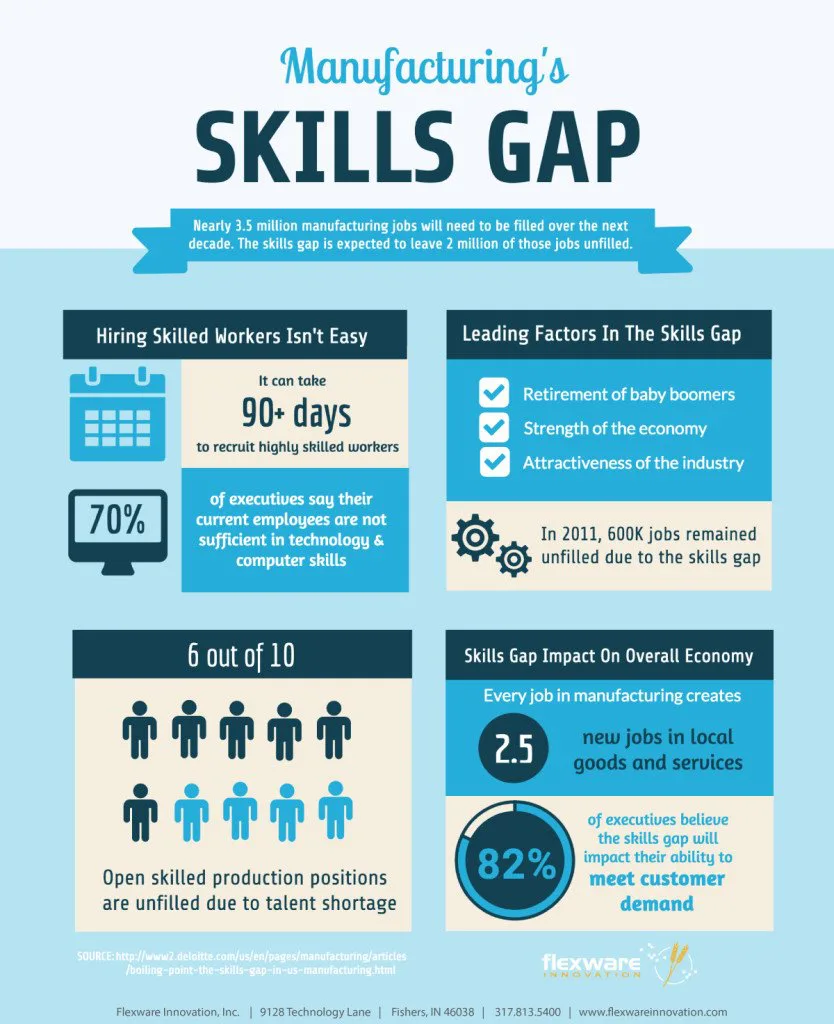

Flexware Innovation: CREATIVITY IN MANUFACTURING?

Understanding the Skills Gap in Manufacturing

The skills gap in manufacturing refers to the disparity between the skills employers need in their workforce and the skills employees possess. As technology evolves, the demand for advanced skills in automation, data analysis, and other specialized areas has outpaced the rate at which workers acquire these skills.

The Perplexity of the Skills Gap

Perplexity arises when the industry faces a paradox—job openings coexist with high unemployment rates. While there are jobs available, they require skills that the current workforce lacks. This perplexing situation creates a barrier to growth for both manufacturers and job seekers.

Dennis Winters, the chief economist for the Wisconsin Department of Workforce Department, and Ryan Stultz of Manpower’s Experis arm agreed workforce growth will be less than 0.5 percent over the next 20 years. That’s because the population is aging, baby boomers are retiring and there aren’t enough young workers in the pipeline to take their places.

Winters likened the situation to a high school football team with eight players instead of 11 on the field at any given time. No matter how skilled those eight may be, he said, they can’t compete in an 11-player game.

“It’s going to get worse,” added Stultz, who noted 21 percent of manufacturing workers will retire in the next eight years and 24 percent of manufacturing workers are 55 or older.

Wisconsin State Journal

Burstiness in Manufacturing: A Double-Edged Sword

Burstiness refers to the sporadic nature of skills demand in the manufacturing sector. The industry experiences sudden bursts in the need for specific skills due to technological advancements or market changes. This burstiness, while a sign of innovation, exacerbates the skills gap as workers struggle to keep up with the rapidly changing requirements.

Like many other industries, the manufacturing sector is currently experiencing a talent shortage. In fact, the industry will have a shortage of an estimated six million employees by 2030. There are many contributing factors at play, some more temporary than others.

One main key contributing to this is the technological advancement in the field. Technology is evolving and changing faster than ever before and its effect on manufacturing is stark. As more advancements arise, the necessary skillsets in the industry change, which leads to a skills gap.

Michael Page: "How Technological Advancements in Manufacturing are Affecting the Labor Shortage"

The Role of Nearshore Manufacturing

Nearshore manufacturing involves outsourcing production to facilities in close geographic proximity. Mexico has emerged as a prime nearshore destination for U.S. manufacturers, offering a solution to the skills gap.

Advantages of Nearshore Manufacturing in Mexico

- Proximity and Collaboration: Nearshore manufacturing allows for closer collaboration between the home country and the manufacturing facility. This proximity facilitates the exchange of knowledge and expertise, helping bridge the skills gap.

- Skilled Workforce: Mexico boasts a skilled workforce with expertise in various manufacturing processes. Companies can tap into this talent pool, reducing the impact of the skills gap on their operations.

- Cost-Effectiveness: While addressing the skills gap, nearshore manufacturing in Mexico provides cost advantages, making it an economically viable solution for companies seeking skilled labor without breaking the bank.

Challenges of Nearshore Manufacturing

- Cultural Differences: Despite the geographical proximity, cultural variations can pose challenges in communication and collaboration. Adapting to these differences is crucial for successful nearshore partnerships.

- Logistical Concerns: Managing the supply chain and logistics can be complex when manufacturing across borders. Companies must navigate these challenges to ensure seamless operations.

Conclusion: Nearshore manufacturing in Mexico emerges as a strategic option to skills gaps

In conclusion, the skills gap in manufacturing poses a significant challenge, but solutions are within reach. Nearshore manufacturing in Mexico emerges as a strategic option, offering a skilled workforce and proximity advantages. However, success requires navigating challenges and adopting a comprehensive strategy to cultivate a skilled workforce for the future.

FAQs About Nearshore Manufacturing

Q1: How does nearshore manufacturing differ from offshore manufacturing? Nearshore manufacturing involves outsourcing to a nearby country, often sharing a border, while offshore manufacturing involves outsourcing to a more distant location, often across oceans.

Q2: What industries benefit the most from nearshore manufacturing in Mexico? Industries such as automotive, electronics, and aerospace have found significant advantages in nearshore manufacturing in Mexico due to the skilled workforce and cost-effectiveness.

Q3: How can companies overcome cultural differences in nearshore manufacturing partnerships? Building cultural awareness, providing cross-cultural training, and fostering open communication are crucial for overcoming cultural differences in nearshore manufacturing collaborations.

Q4: Are there government incentives for companies engaging in nearshore manufacturing in Mexico? Yes, the Mexican government offers various incentives, including tax breaks and subsidies, to attract and support companies engaging in nearshore manufacturing.

Q5: Can nearshore manufacturing help small and medium-sized enterprises (SMEs) address the skills gap? Absolutely. Nearshore manufacturing allows SMEs to access skilled labor without the extensive resources required for in-house skill development, helping them remain competitive in the market.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.