Component Sub Assembly

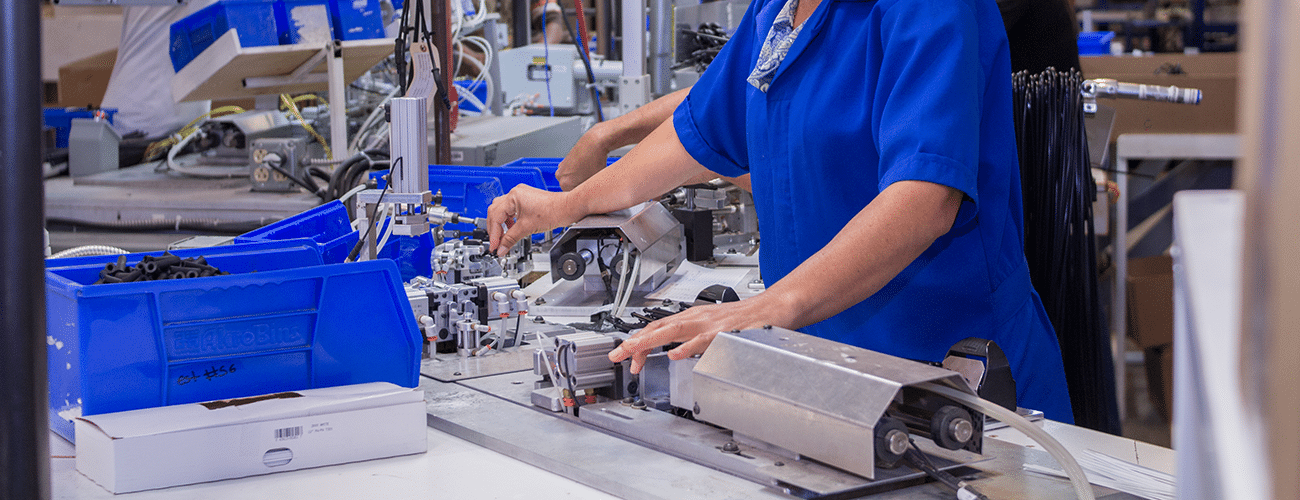

With 30 years' experience in full service manufacturing, NovaLink can handle all your Component Sub Assembly needs. Get a Free Consultation.

Component Sub Assembly Enables Your Lean Manufacturing Objectives

NovaLink offers a wide range of nearshore manufacturing services, including component sub assembly. NovaLink can manage all the steps of Chip on Carrier, Optical SubAssembly, Butterfly lasers, 2.5G DFB, and 10G EML TOSAs. If it’s a product that requires precision and high tolerance, or if it’s commoditized, NovaLink has an edge. Component Sub Assembly with on-time delivery helps your business achieve lean manufacturing goals like reducing labor and inventory costs. NovaLink can handle all your Component Sub Assembly needs and offers you the benefit of 30 years of experience in full service manufacturing.

NovaLink Manufacturing Facility Video

NovaLink has released a new video highlighting the versatility of their manufacturing facility in Matamoros, Mexico. In this video, you will be able to see the factory and its associates in action. The video, which was filmed on the floor of the manufacturing facility, illustrates the variety of manufacturing operations and the wide range of skills represented by the workforce. As well as demonstrating NovaLink's commitment to first class manufacturing, the video also emphasizes its commitment to safety protocols for the health of its workers and clients.

Sub-Assembly Manufacturing in Mexico: A Cost-Effective Solution for Your Business

In this article, we will delve into the world of sub-assembly manufacturing in Mexico and explore the key benefits and reasons for its rising prominence in the global market.

The NovaLink Advantage

NovaLink is committed to the philosophy that transitioning manufacturing to Mexico should be an easy, rapid and cost-effective process. We offer the following advantages to enable our customers to succeed.

Ability to Scale

NovaLink can initiate a manufacturing relationship with a floor plan as small as 5,000 square feet. Once the relationship has been established, and proven successful, customers can scale up to 100,000 square feet or more. It also permits larger customers to scale down if the customers’ business experiences a need to reduce overall capacity.

Attractive Labor Pool

Mexico has made large strides in developing a world class labor market. NovaLink has positioned itself and helped develop a geographical market of labor that is pro-business resulting in lower than normal turnover rates.

No Significant Upfront Capital Commitment

NovaLink client’s are not required to enter into any long-term lease obligations or purchase new equipment (if currently owned). Furthermore, the client’s equipment can be shipped to NovaLink’s facilities in stages as production ramps to ensure quality control.

Quick Turnaround

With our proximity to market, short lead times are met with turns from order placement as short as five days.

Simple Pricing

NovaLink offers a variety of pricing models to accommodate unique client needs. These range from fully loaded hourly rates to a full package model where NovaLink provides the raw materials and equipment.

Site Selection and Raw Materials Procurement

NovaLink can accommodate your operations within our current facilities, or if you prefer your own facility, assist in site selection, secure all permitting requirements and coordinate this effort with a builder or landlord. Many of our customers have dedicated suppliers in place, but for those that do not, NovaLink will assist in source materials and provide cost estimates.

Manufactured Products That Can Be Assembled in Mexico

Subassembly is required after the components of your product have been manufactured. A subassembly can be labor-intensive and expensive to manufacture, depending on the complexity of your product. However, as with any complex manufacturing problem, the easiest solution may lie just south of the border: Mexico.

CASE STUDY: Amerex Corporation

Amerex, like many companies performing large-scale manufacturing that required sub-assembly of their products, began to face mounting pressure from their competitors that were having products produced in Asia. In order to remain competitive, Amerex needed an assembly in Mexico solution to meet the price pressures from the Asian market.

Are You Ready to Begin Manufacturing in Mexico? Contact Us for a Free Consultation

Contact us and let's start building something!

Use the details to the right to contact NovaLink.

Office

6665 Padre Island Highway

Suite B

Brownsville, Texas 78521

Hours

Mon-Fri: 8am - 5pm