Last Updated on April 19, 2023

If you're a US-based manufacturer looking to expand your operations, you might be wondering whether Mexico manufacturing is the right choice for you. While outsourcing manufacturing operations to another country can seem daunting, there are several benefits to manufacturing in Mexico that should not be ignored. In this blog post, we'll discuss seven horrible mistakes you might be making by not manufacturing in Mexico.

You Haven’t Thought Through the Logistics

Make sure you take the time to ask the important logistical questions first:

- How complex is this product to produce?

- Does an engineer have the opportunity to review this product in order to gain a better understanding of what is involved in its production?

- Based on the costs and overhead involved, how many of these products can you produce?

The success of your product depends on knowing these answers in advance.

Manufacturing Processes and Industries Are Not Familiar to You

Having knowledge of your own manufacturing is preferred for you to be a contributing factor in the success of the program. This is especially important if you are not manufacturing in Mexico. Your involvement in the manufacturing process, including its setup and approval, will play a vital role in the successful launch of your product.

If there are problems or changes you would like to make, your knowledge of Mexico manufacturing will allow you to do this without delaying or sabotaging your process.

You Are Missing Cost Savings Opportunities

One of the most significant benefits of Mexico manufacturing is cost savings. Mexico offers lower labor costs than the US, which can result in significant cost savings for manufacturers. Additionally, Mexico has several free trade agreements with countries around the world, which can result in reduced tariffs and lower costs for importing and exporting goods.

You Are Trying to Manufacture Without a Partner

Full service manufacturing without a partner like NovaLink is taking the much harder road in your product’s success. This is especially true if you are manufacturing for the very first time or you have decided to use Mexico manufacturing destination.

Nearshore Manufacturing Partners like NovaLink have over 30 years in experience in manufacturing as well as a solid process for getting your project started rapidly and correctly. Leveraging this experience will aid you in overcoming the problems and processes of which you have no experience.

Not Having Proximity to the US Market

Mexico's close proximity to the US market is another significant advantage of manufacturing in Mexico. By manufacturing in Mexico, companies can reduce transportation costs and lead times, enabling them to get their products to market faster and more cost-effectively. According to the Institute for Supply Chain Management:

Shorter lead times result in better inventory management, enabling lean manufacturing and faster cycle times. In addition, he adds, free trade agreements provide lower tariffs. “Time zones are better for North American supply chains, and our cultural similarities bring more benefits says Pablo Garza, head of growth and innovation for Mexico-based Akzent Group

Losing the Opportunity to Expand Operations

Manufacturing in Mexico can also provide companies with the opportunity to expand their operations into new markets. Mexico is a hub for manufacturing, and many US-based companies have successfully expanded their operations into Mexico, enabling them to tap into new markets and grow their business through cost savings.

Missed Opportunity to Improve Efficiency

Not manufacturing in Mexico means companies are missing out on the opportunity to improve their efficiency by streamlining their manufacturing operations. With lower labor costs, companies can invest in new technologies and equipment to improve their efficiency and reduce waste. Additionally, Mexico has a strong infrastructure that supports manufacturing operations, enabling companies to optimize their supply chain and reduce costs.

Committing to an Unrealistic Overhead Structure & Underestimating Production Costs

If you have problems with gaining traction for your Mexico manufacturing, you may be committing to a structure for your manufacturing that you cannot fulfill. It is better (again, with a partner) to work with an infrastructure that allow you to grow into your needs: As your manufacturing project succeeds and grows, the manufacturing infrastructure will grow with you.

Manufacturing costs can quickly add up, and failing to accurately estimate these costs can result in overspending and reduced profits. To avoid this mistake in Mexico manufacturing, create a detailed cost analysis that includes expenses such as labor, materials, equipment, and overhead costs.

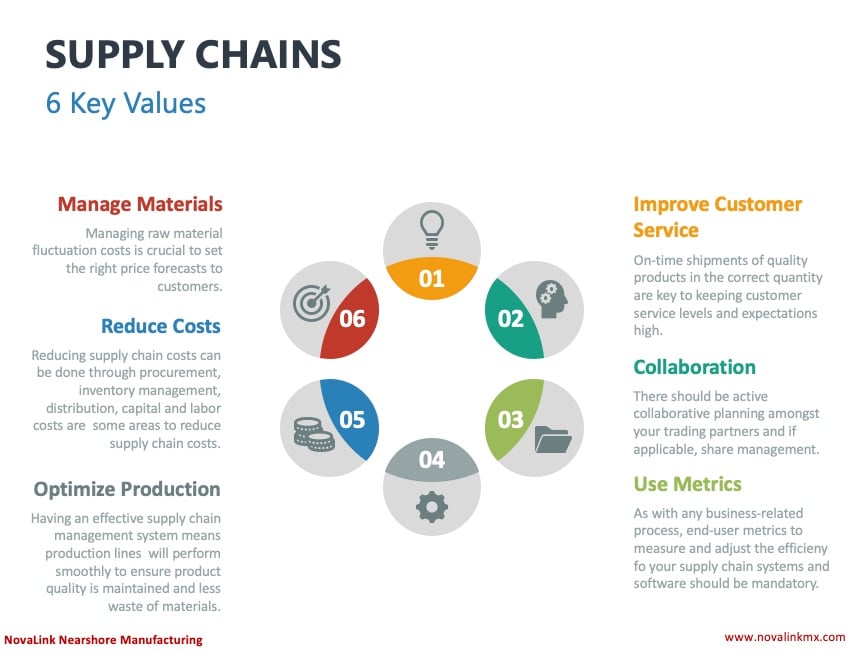

You Are Not Managing Your Supply Chain Correctly

Manufacturing in Mexico can also help companies diversify their supply chain, reducing their reliance on a single supplier or location. By diversifying their supply chain, companies can mitigate risk and ensure continuity of supply. Getting your product to market quickly and efficiently, and most importantly, cost effectively, are vital to the success of your manufacturing project. Managing your supply chain is often at the very core of this. Having a good understanding of the following will save your operation money in the long run:

- Sourcing and Procurement

- Inventory/Warehouse Management

- Finished Product Distribution

- Transportation

- Customs Brokerage (if you are using a nearshore location)

Overlooking Intellectual Property Protection

Manufacturing often involves developing new products and technologies that require intellectual property protection. One mistake companies make in Mexico manufacturing is overlooking the importance of protecting their intellectual property, such as patents and trademarks.

Mexico's intellectual property protection laws protect companies' most valuable assets in an era of increasing economic disruption. To avoid this mistake, work with an intellectual property attorney to establish protection for your company's intellectual property.

Failing to Conduct Due Diligence

Before outsourcing manufacturing to a third-party vendor in Mexico, it's essential to conduct due diligence. One common mistake is failing to research the vendor's capabilities, certifications, and experience. If you're considering outsourcing to Mexico manufacturing, be sure to research the vendor's experience working with US-based companies, their certifications and accreditations, and any past customer reviews.

Not Manufacturing in Mexico, but in China: A Clarification

When faced with the choice of Manufacturing in Mexico vs China, the most popular option may not be the most cost effective. Since July of 2020, the United States has imposed a 25 percent border tax on goods made from factories in China when they’re imported into the US. The goal of this tax, and the other China tariffs, is to make Chinese products more expensive for American consumers and businesses to buy.

Manufacturing goods and services between Mexico, Canada, and the United States has become easier and more cost-effective thanks to the new trade agreements:

- There are no tariffs for products made in Mexico and imported into the United States that meet USMCA rules of origin requirements.

- Lower shipping time for goods to get into the United States

- Lower average cost of shipping

- Lower number of days to start manufacturing operations

- Cost-effective and more productive labor pool

Missing Out on Opportunities: The Risks of Not Manufacturing in Mexico

To sum up, if you're not manufacturing in Mexico, you may be committing some serious mistakes. You could be overlooking Mexico's advantages, such as lower labor costs, skilled labor force, proximity to the US market, and opportunities for expansion and improved efficiency. Ignoring these benefits means missing out on substantial cost savings and growth prospects. Furthermore, failing to diversify your supply chain and take advantage of Mexico's economic growth exposes your company to unnecessary risk. Therefore, if you're planning to expand your manufacturing operations, consider Mexico manufacturing as a viable option. By doing so, you can harness all the advantages that Mexico offers and position your business for long-term success.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.