Last Updated on January 22, 2025

When you think about moving a manufacturing operation closer to home, does Mexico come to mind? It should. The trend of nearshoring to Mexico isn’t just picking up steam—it’s reshaping the global supply chain. So, what’s behind this surge? And why are industries like furniture manufacturing making Mexico their go-to destination? Let’s unpack this.

Investment in Mexico as a Manufacturing Destination

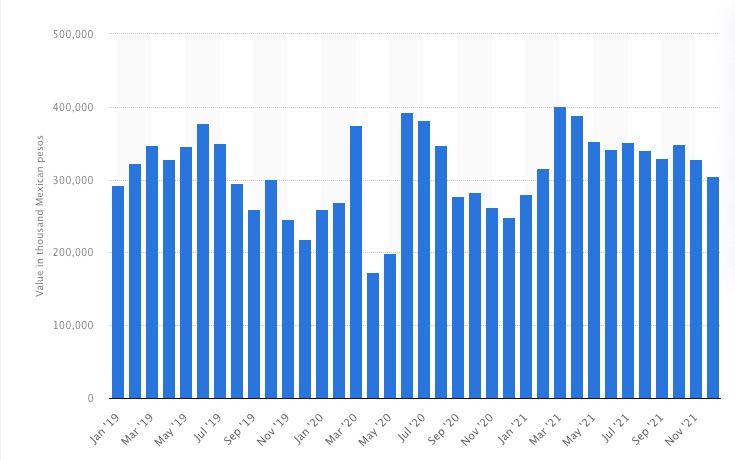

The Ministry of Economy reports that Mexico received more than USD 32.9 billion in foreign direct investment in the third trimester of 2023. The flow of foreign direct investment has also improved over the past ten years, with a total of USD 300 billion between 2011 and 2021, primarily for manufacturing, finance, mining, commercial, construction, real estate, tourism, media, professional services, and transportation.

According to the World Investment Report 2024 published by the United Nations Conference on Trade and Development (UNCTAD), Mexico ranked 9th place as foreign direct investment recipient, and 3th among developing economies. - Mexico Projects

Proximity Makes Perfect

Ever heard the saying, “Location is everything”? That’s especially true for manufacturing. Mexico’s geographic closeness to the U.S. offers unbeatable advantages. Freight costs drop significantly when your goods don’t have to cross oceans. Plus, shorter transit times mean faster delivery to your customers. You’re not just saving money—you’re boosting efficiency.

But it’s not just about shipping. Proximity also makes collaboration easier. Want to visit a plant or inspect a production line? It’s just a quick flight, not a logistical headache. That level of accessibility is a game-changer.

The Cost Advantage: More Than Just Labor

Let’s talk dollars and cents. Labor costs in Mexico are far more competitive than in the U.S., but it doesn’t stop there. Energy, raw materials, and even real estate are more affordable south of the border.

Trade Agreements Seal the Deal

Ever heard of the USMCA? This trade agreement between the U.S., Mexico, and Canada eliminates many of the tariffs that could otherwise eat into your profit margins. For industries that rely on cross-border supply chains, the benefits are clear. Combine that with Mexico’s extensive network of trade agreements worldwide, and you’ve got a recipe for global competitiveness.

A Thriving Manufacturing Ecosystem

Here’s the thing: Mexico isn’t just a great option—it’s becoming the option for many manufacturing industries. Clusters of suppliers, skilled workers, and assembly operations are already in place. Need specialized components or high-quality processes? Chances are, you’ll find a local partner who’s already a pro at it.

And let’s not forget sustainability. Many of Mexico’s manufacturers are prioritizing eco-friendly practices. If your brand values sustainability, this alignment can resonate with customers who care about responsible sourcing and production.

The Transition From Offshoring to Nearshoring to Mexico

Many companies initially saw moving manufacturing to low-cost hubs like China as a golden ticket to big savings—even if it meant setting up shop halfway across the globe. On paper, the numbers looked great. But over time, the story shifted, and the long-term practicality of this approach started raising some eyebrows.

Labor costs in places like China have risen sharply in recent years, chipping away at the cost advantage. And it’s not just about dollars and cents—there’s a growing list of headaches that come with these distant locations. Security concerns and intellectual property risks? Check. Add to that the challenges of managing big cultural, language, and time-zone differences, and it’s clear that these "savings" come with strings attached.

Think about it: if your production gets delayed or your intellectual property is compromised, what happens to your bottom line? What seemed like a savvy cost-cutting move can turn into a high-stakes gamble.

These days, businesses are starting to ask smarter questions. Is chasing lower labor costs worth the trade-offs in supply chain reliability? How can we stay competitive without putting everything at risk? The answers are leading many to reconsider their options and explore more balanced, sustainable manufacturing strategies.

Industries Set to Benefit from Nearshoring

As a result of its strong interdependence with the US economy, Mexico is well positioned to benefit from nearshoring. Mexican manufacturers have a strong technical capability, including cutting-edge automation.

Medical: Medical devices remain the most important industry to nearshore to Mexico. It is a well known fact that Mexico is a highly valued production location for many types of plastic injections, assemblies, efficient cutting and sewing, etc.

Appliances: According to the Office of Technology Evaluation, in 2021, U.S. imports of Machinery and Mechanical Appliances from Mexico also increased from $121.5 billion in 2020 to $141.4 billion, making up 17.2% of all U.S. imports of those commodities worldwide. According to Investopedia, Mexico is a large producer of home appliances, including washing machines, refrigerators, and air conditioners. In this category, Mexico accounts for between 30% and 44% of U.S. imports.

Challenges and How to Overcome Them

Of course, no location is perfect. Navigating a new regulatory environment or cultural differences can feel overwhelming. But here’s the good news: resources like nearshoring consultants and local business partnerships can make these hurdles manageable.

Think of it as building a house. The framework—proximity, cost savings, trade agreements—is already solid. You just need the right tools and guidance to complete the project.

The Bottom Line

Nearshoring to Mexico isn’t just a trend—it’s a smart, strategic move for industries looking to grow and adapt in a competitive market. From cost savings to faster delivery times, the benefits are too significant to ignore. And with Mexico’s manufacturing ecosystem only getting stronger, there’s never been a better time to make the shift.

So, what’s stopping you? The opportunity is right there, just across the border. Are you ready to take it?

FAQs about Why More Manufacturing Industries are Nearshoring to Mexico

Q1: Why are more manufacturing industries choosing to nearshore to Mexico?

A1: There are several reasons why more manufacturing industries are nearshoring to Mexico. Mexico offers a strategic location with proximity to major consumer markets in North America. It provides a skilled and cost-effective labor force, a robust infrastructure, favorable trade agreements, and a stable business environment. Nearshoring to Mexico allows companies to reduce costs, improve supply chain efficiency, and maintain close collaboration with their operations.

Q2: Is nearshoring to Mexico only beneficial for specific manufacturing industries?

A2: Nearshoring to Mexico is not limited to specific manufacturing industries. Various sectors, such as automotive, aerospace, electronics, medical devices, consumer goods, and many more, have found success in nearshoring their operations to Mexico. The country offers a diverse manufacturing landscape that can cater to different industry requirements and product types.

Q3: Are there any challenges that manufacturing industries may face when nearshoring to Mexico?

A3: While nearshoring to Mexico offers numerous advantages, there can be challenges to consider. These challenges may include navigating cultural differences, language barriers, supply chain logistics, managing cross-border operations, and complying with local regulations. However, partnering with experienced nearshore service providers and implementing effective communication and project management strategies can help mitigate these challenges.

Q4: Can nearshoring to Mexico result in cost savings for manufacturing industries?

A4: Yes, nearshoring to Mexico often leads to cost savings for manufacturing industries. Factors such as lower labor costs compared to developed countries, reduced transportation expenses, decreased inventory carrying costs, and streamlined supply chain operations contribute to overall cost savings. Mexico's cost advantages make it an attractive option for companies looking to optimize their manufacturing operations.

Q5: How does nearshoring to Mexico contribute to supply chain efficiency?

A5: Nearshoring to Mexico improves supply chain efficiency in several ways. The proximity to major consumer markets in North America reduces transportation lead times and costs. It allows for just-in-time inventory management, easier collaboration with suppliers, and more efficient order fulfillment. Additionally, Mexico's established logistics infrastructure and border proximity facilitate smooth movement of goods, enhancing supply chain responsiveness.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about Nearshoring Manufacturing to Mexico with our curated collection of related blog posts.

- Can Moving Manufacturing to Mexico Really Be Turnkey? Here’s What You Need to Know

- What Type of Company Should Not Move to Mexico?

- Stop Overpaying Overseas: Move Your to Manufacturing Mexico and Save Big

- Why Mexico Is Beating Asia for Fast Turnaround

- Stop Waiting: Mexico Product Manufacturing Is Ready When You Are

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.