Last Updated on February 26, 2024

In this article, we will look at the importance of scaling up manufacturing and how it can help your business not only in good times but also in bad ones. We will also discuss the distinction between scaling up manufacturing operations and capacity building, as well as the importance of scalability in a manufacturing operation and how it will bring you into contact with others to help you grow your manufacturing business.

You should not be fearful of success as a manufacturer; you should plan on scaling up production from the beginning. The method of doing this will depend on the type of products you manufacture. But one thing that can be planned for is finding a manufacturing partner who can help your business grow or scale back as needed.

The Difference Between Scaling Up and Capacity Building

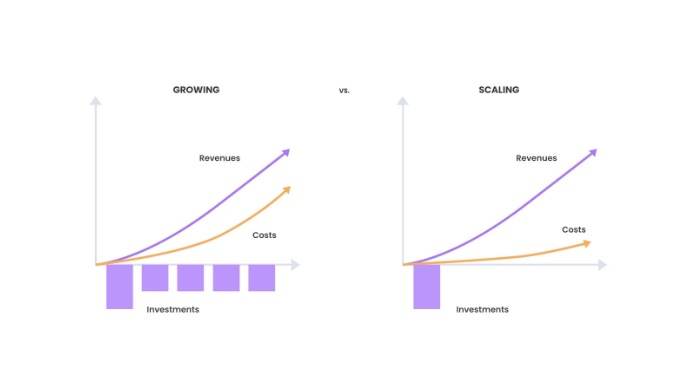

When defining capacity building in manufacturing, it is imperative to distinguish between scaling up manufacturing and building capacity. Although scaling up and capacity building are different methodologies, there are similarities between them. Why should I consider scaling up manufacturing and what is the difference?

"By definition, the difference between scaling up and capacity building is that in the latter, a company is expanding its ability to manufacture more to meet a higher demand. On the other hand, scaling up is the ability to manufacture to meet market demand — in other words, the ability to scale up or scale back without great cost or risk to the organization while maintaining margins. Scalability, when applied to manufacturing, is the ability to reconfigure manufacturing systems, allowing production capacity to be quickly adjusted to abrupt changes in market demand while maintaining cost efficiencies."

Thomasnet

Scaling Up Manufacturing

Scaling up in manufacturing refers to increasing production volume efficiently without compromising quality or safety. It's crucial for businesses that experience growth in demand for their products. Here's why it's important:

Benefits of Scaling Up:

- Increased Revenue and Profit: More products sold equals more potential revenue and profit.

- Economies of Scale: Buying materials and equipment in bulk often leads to lower per-unit costs.

- Market Share and Brand Recognition: Meeting higher demand allows you to capture a larger market share and boost brand recognition.

- Operational Efficiency: Streamlining processes and optimizing production can lead to faster turnaround times and lower costs.

- Competitive Advantage: Scaling up helps you stay ahead of competitors who struggle to meet growing demand.

Source: https://www.frontiersin.org/articles/10.3389/fenvs.2019.00165/full

Simply put, when scaling up your business, you should not be planning to reach higher demand, but to meet more market demand. Demand may increase or decrease, and the ability to scale in either direction without affecting your bottom line should be the goal of all businesses, not just manufacturers.

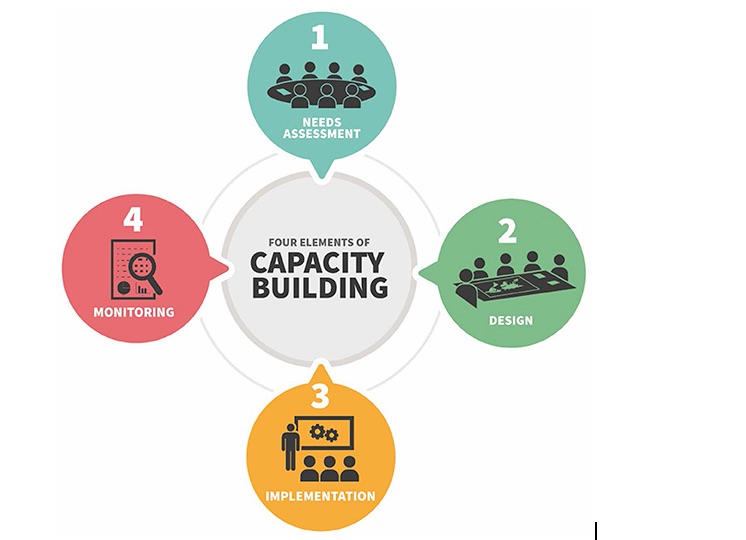

Capacity Building:

- Focuses on: Optimizing internal capabilities to produce more without substantial hardware changes. The goal is to be more efficient with existing resources.

- Methods: Streamlining processes, implementing lean manufacturing principles, cross-training employees, using automation and technology for greater efficiency.

- Impact: Gradual increase in production capacity through improved efficiency. It's a proactive approach to long-term growth.

- Risks: Requires investment in training and technology, potential resistance to change from employees.

In times of prosperity, building capacity for a market leads to overproduction, while in times of difficulty, it leaves them with unsellable products. The problem does not affect manufacturing businesses that are built on the concept of scaling up or down.

The Importance of Scalability

Scalability in manufacturing is crucial for various reasons, primarily because it enables companies to adapt and thrive in a dynamic business environment. Here's why scalability is important:

- Meeting Demand Fluctuations: Manufacturing demands can vary significantly due to changes in consumer preferences, market trends, or unforeseen events like pandemics or supply chain disruptions. Scalability allows manufacturers to ramp up or down production levels swiftly to match these fluctuations, ensuring they can meet customer demands efficiently.

- Cost Efficiency: Scalability enables manufacturers to optimize their resources effectively. By scaling production based on demand, companies can minimize excess inventory, reduce production downtime, and streamline operations, leading to lower costs per unit produced.

- Flexibility and Adaptability: In today's fast-paced market, businesses need to be agile and adaptable. Scalability allows manufacturers to respond quickly to changes in the market, technological advancements, or regulatory requirements. Whether it's introducing new product lines, adopting innovative manufacturing processes, or expanding into new markets, scalable operations provide the flexibility needed to seize opportunities and stay competitive.

- Risk Mitigation: Scalability reduces the risk associated with manufacturing operations. By spreading production capacity across multiple facilities or utilizing flexible production lines, companies can mitigate the impact of disruptions such as equipment failures, natural disasters, or geopolitical events. Diversifying production capabilities ensures continuity of supply and minimizes the risk of revenue loss due to unforeseen circumstances.

In order to maintain growth and profitability, you must be able to adapt to the changing demands of the market. In the course of expanding your manufacturing operation, your primary focus will be on meeting the needs of your market and customers.

"Many successful entrepreneurs are constantly thinking of how to scale their business for growth. Whether you’re developing new products or services, taking on larger orders or moving into the export market, business owners need both the capacity and capability to do this successfully."

Clydesdale Bank

Adaptability in Manufacturing Operations

According to a recent McKinsey survey of 1,240 business leaders worldwide, nearly 80 percent say capability building is extremely or very important to the long-term growth of their organizations.

This action, however, is complicated by the fact that market demands are always changing; they are constantly in flux, so your manufacturing production may be impacted by interest in your business, updated products, and the availability of materials to meet your product's demand.

As a result, if you wish to remain competitive in the face of these conditions, your manufacturing operation must be able to adapt the model in terms of scalability in order to meet current market requirements.

Source: https://treinetic.com/scaling-a-business/

Maintaining Lean Supply Chains and Scaling Up Manufacturing in 2024: The Reshoring Advantage

Your supply chain, which is one of the most critical aspects of your business, will also benefit from scaling up manufacturing operations. With shortages and delays in your supply chain, how will you manage production in your manufacturing operation?

Balancing a lean supply chain with scaling manufacturing presents a significant challenge in 2024. However, reshoring manufacturing can offer a unique solution by:

Improving Scaling:

- Increased agility: Closer proximity to your market allows for faster response to demand fluctuations, enabling quicker production adjustments and reduced lead times.

- Enhanced control: Bringing production closer simplifies communication, coordination, and decision-making within your teams, streamlining scaling efforts.

- Talent access: Tapping into your local talent pool provides easier access to skilled workers and facilitates training for specific needs.

Maintaining Leanness:

- Reduced transportation costs: Shorter transportation distances mean lower shipping costs, leading to reduced inventory holding needs and improved cash flow.

- Simplified logistics: Fewer intermediaries in the supply chain reduce complexity and potential disruptions, contributing to overall leanness.

- Improved quality control: Closer proximity to production allows for stricter quality checks and faster problem resolution, minimizing waste and rework.

Additional benefits:

- Strengthened intellectual property protection: Reshoring reduces the risk of intellectual property theft and unauthorized production.

- Enhanced sustainability: Reduced transportation emissions contribute to lower environmental impact and improved brand image.

- Greater community impact: Supporting local jobs and economies fosters goodwill and builds community loyalty.

Reshoring is being used to make it easier for companies to keep up with changing consumer demands and meet deadlines; resilient supply chains are a cornerstone of a company’s success. This strategy is picking up momentum—take China, for example. Long an incredibly popular option for cheap overseas manufacturing, many companies have either moved some of their manufacturing from China back to the US or plan to do so in the next few years. While individual company stability is a major driver here, national security and the US’ overall economic health also play a part, with tensions around trade between the two major countries at a high point in recent years.

Supply Chain Executive

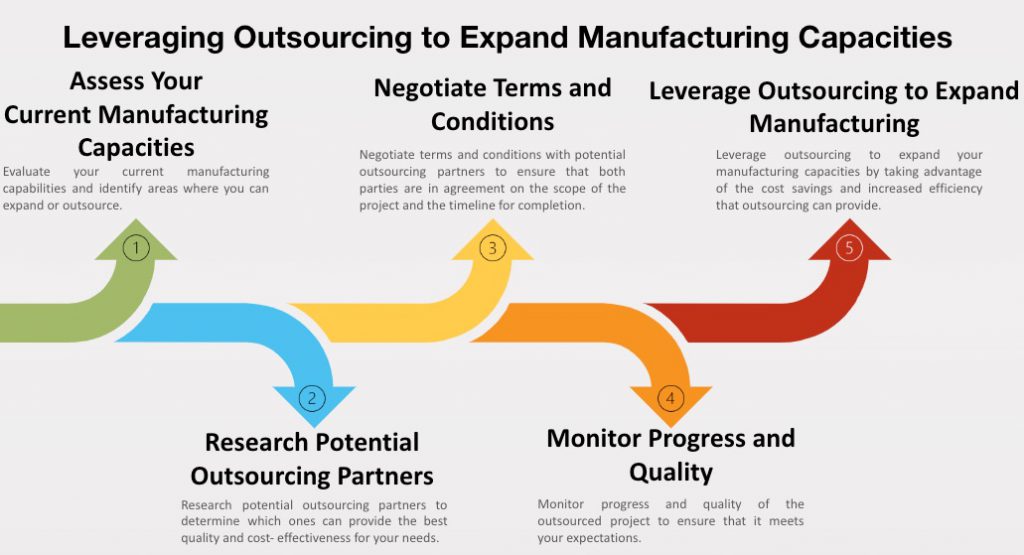

Scaling up Manufacturing With a Nearshore Partner

In addition to reshoring production capacity, partnering with an established nearshore manufacturing provider can further augment a company’s ability to scale up operations quickly when needed. Locating a flexible production partner in geographies like Mexico allows for proximity to North American headquarters at a lower cost than manufacturing solely onshore. The operational expertise, specialized equipment, and skilled workforce an experienced nearshore provider possesses would be costly and time-consuming to build organically. By collaborating hand-in-hand with an adept nearshore manufacturing partner, companies can rapidly expand output by leveraging existing infrastructure just a short distance away rather than starting from scratch.

Once a relationship is established, the nearshore partner operates as an extension of the home office. Joint processes can identify shifts in forecasted demand and production requirements months or quarters in advance. This enables the nearshore site(s) to add additional lines, staff, shifts and resources. Their expertise in scaling operations helps mitigate overextension risk during periods of peak demand. This close collaboration allows for transparency, communication, and responsiveness - supporting the overall goals of lean, resilient and adaptable supply chains. The rapid scalability and established capabilities a strong nearshore manufacturing partner offers is key to cost-effectively achieving production growth targets.

Case Study: Turtle Fur

Turtle Fur, a manufacturer of cold weather accessories, needed garment production, but also required the manufacturing output and labor pool to scale up and decrease for their seasonal production (up to a 20% increase or decrease depending on the season). It was not economical feasible to maintain a large labor force throughout the year. Further, Turtle Fur required its workers to be capable of working on several different types of products based on demand, and not specialized.

NovaLink met Turtle Fur's greatest need, flexible staffing. With NovaLink, they provided cross-trained staff for 20% increases/decreases for seasonal production runs and demand.

With a cross-trained staff, Turtle Fur can move labor between production lines (sometimes daily) as needed: the same core group of employees makes knitted hats, electric socks, ski neck warmers, gloves, and children’s mittens from the same production line. Turtle Fur meets seasonal sales deadlines due to staff adaptability and ease of access to the Mexican market.

Turtle Fur's production flexibility enables it to increase production as e-commerce demand increases; Turtle Fur can increase production as e-commerce demand increases.

Conclusion: Your Manufacturing Business Should Be Planned for Growth From the Onset.

You should choose a manufacturing partner who can help your business grow or scale back as necessary. In addition to shelter and contract manufacturing services, NovaLink has over 30 years of experience in a wide range of industries. As far as cost, quality, productivity, and delivery are concerned, NovaLink believes that full service manufacturing in Mexico is the best option. As a manufacturing partner, NovaLink would be a great choice for your company as it grows and scales back its operations.

FAQs for Scaling Up Manufacturing

- What does scaling up manufacturing mean?

Scaling up manufacturing refers to the process of increasing production capacity to meet growing demand. It involves expanding operations, optimizing processes, and increasing output while maintaining quality standards. - Why is scaling up manufacturing important?

Scaling up manufacturing is essential for businesses to keep up with market demand and achieve growth objectives. It allows companies to increase sales, capture a larger market share, and maximize profitability. By scaling up, manufacturers can meet customer expectations and stay competitive in the industry. - What are the challenges involved in scaling up manufacturing?

Scaling up manufacturing can present several challenges, including:

a) Capital investment: Expanding production requires significant financial resources to invest in infrastructure, equipment, and skilled labor.

b) Supply chain management: Scaling up often involves sourcing raw materials and components in larger quantities, which can strain the supply chain and require adjustments to ensure timely delivery.

c) Operational efficiency: Increasing production may expose inefficiencies in existing processes. Streamlining operations and implementing automation technologies are crucial to maintaining productivity.

d) Workforce management: Hiring and training an adequate workforce to handle increased production volumes can be a challenge, as it requires finding qualified individuals and ensuring a smooth transition.

- How can manufacturers plan for scaling up?

To effectively plan for scaling up manufacturing, manufacturers should consider the following steps:

a) Market research: Conduct a thorough analysis of market trends, demand forecasts, and customer preferences to identify growth opportunities.

b) Capacity assessment: Evaluate existing production capabilities and identify areas for improvement or expansion, considering factors such as machinery, space, and workforce.

c) Process optimization: Streamline operations and eliminate bottlenecks by analyzing workflows, implementing lean manufacturing principles, and adopting automation technologies where appropriate.

d) Supply chain management: Strengthen supplier relationships, negotiate favorable contracts, and assess logistics to ensure a reliable and efficient supply chain that can support increased production.

e) Financial planning: Develop a detailed budget that includes the cost of expanding facilities, equipment, and personnel. Explore financing options, such as loans or partnerships, to secure the necessary capital.

- What are some best practices for scaling up manufacturing successfully?

To achieve successful scaling up, manufacturers should consider the following best practices:

a) Incremental approach: Gradually increase production capacity and monitor performance at each stage to identify and address any issues before scaling up further.

b) Technology adoption: Embrace advanced technologies, such as data analytics, Internet of Things (IoT), and artificial intelligence (AI), to enhance productivity, quality control, and operational efficiency.

c) Continuous improvement: Foster a culture of continuous improvement by encouraging employee feedback, implementing regular training programs, and seeking innovative solutions to enhance processes and products.

d) Collaboration and partnerships: Seek collaborations with suppliers, customers, and industry experts to leverage expertise, share resources, and gain insights that can support scaling up efforts.

e) Flexibility and adaptability: Remain flexible and adaptable to changing market conditions, customer demands, and technological advancements to stay ahead of the competition and ensure sustained growth.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.