Last Updated on May 24, 2023

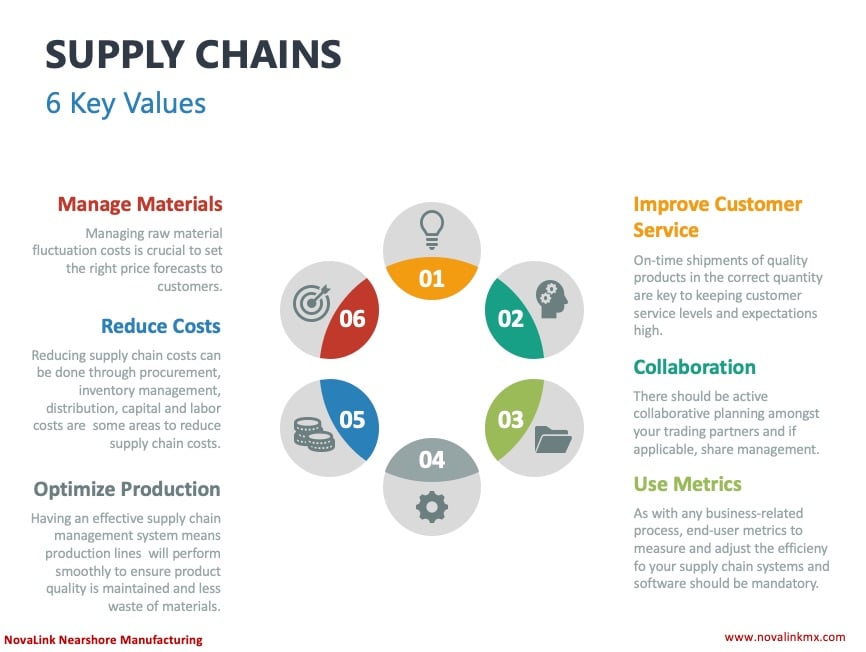

Supply chains are complex networks of organizations, processes, and resources that are responsible for the efficient movement of goods and services from suppliers to customers. To ensure the success and competitiveness of supply chains, it is crucial to uphold each key value in supply chains that drive excellence and contribute to overall business performance.

Value 1: Managing Materials

Efficiently managing materials is a fundamental value in supply chains. It involves effective inventory management, ensuring that the right amount of materials is available at the right time. By implementing strategies such as just-in-time (JIT) principles, businesses can minimize inventory holding costs while maintaining adequate stock levels to meet customer demands.

Value 2: Reducing Costs

Cost reduction is a critical value in supply chains. By identifying cost-saving opportunities throughout the supply chain, businesses can improve their profitability and competitiveness. Lean manufacturing principles, such as eliminating waste and optimizing processes, play a vital role in reducing costs and enhancing efficiency.

Value 3: Optimizing Production

Optimizing production is essential to ensure the smooth flow of goods through the supply chain. Effective production planning and scheduling help minimize bottlenecks and maximize resource utilization. Continuous improvement methodologies, such as Six Sigma and Kaizen, enable businesses to identify and eliminate inefficiencies, resulting in enhanced productivity and quality.

Value 4: Improving Customer Service

Customer service is one the most important value in supply chains that directly impacts customer satisfaction and loyalty. Understanding customer needs and expectations is crucial in delivering a positive experience. By ensuring quick and accurate order fulfillment, businesses can exceed customer expectations and establish strong relationships, fostering customer loyalty and repeat business.

Value 5: Collaboration

Collaboration is a fundamental value in supply chains that drives effective supply chain management. Building strong relationships with suppliers and partners creates a collaborative ecosystem where knowledge and resources can be shared. Enhanced communication and information sharing lead to improved coordination, reduced lead times, and better responsiveness to customer demands.

Value 6: Using Metrics

Using metrics is essential for measuring and improving supply chain performance. Key performance indicators (KPIs) provide valuable insights into various aspects of the supply chain, including efficiency, quality, and customer satisfaction. By analyzing data and metrics, businesses can identify areas for improvement, implement targeted strategies, and continuously enhance their supply chain operations.

Conclusion: Upholding the Key Values in Supply Chains

In conclusion, the six key values in supply chains—managing materials, reducing costs, optimizing production, improving customer service, collaboration, and using metrics—play crucial roles in ensuring the effectiveness and competitiveness of supply chains. By upholding these values, businesses can achieve operational excellence, deliver value to customers, and drive overall business success.

FAQs

- How can managing materials benefit supply chains?

Efficiently managing materials in supply chains can bring several benefits. By optimizing inventory levels, businesses can reduce carrying costs and minimize the risk of stockouts or excess inventory. It ensures that the right materials are available at the right time, enabling smooth production and timely order fulfillment. Effective material management also supports just-in-time (JIT) principles, reducing waste and increasing overall efficiency.

- What cost-saving opportunities can be identified in supply chains?

There are various cost-saving opportunities in supply chains. By analyzing the entire value chain, businesses can identify areas where costs can be reduced. This may include optimizing transportation routes to minimize fuel expenses, negotiating favorable pricing with suppliers, implementing energy-saving measures in manufacturing processes, or adopting technology solutions to automate manual tasks. Continuous evaluation of cost-saving opportunities is crucial for maintaining a competitive edge.

- How does collaboration impact supply chain performance?

Collaboration plays a vital role in enhancing supply chain performance. By building strong relationships with suppliers, manufacturers, distributors, and other partners, businesses can foster trust, encourage knowledge sharing, and leverage shared resources. Collaboration enables better coordination, streamlined communication, and improved responsiveness to customer demands. It facilitates joint problem-solving and innovation, leading to enhanced efficiency, reduced costs, and increased customer satisfaction.

- What are some commonly used metrics in supply chain management?

There are several metrics used to measure and monitor supply chain performance. Key performance indicators (KPIs) vary depending on the specific objectives of the supply chain. Some common metrics include on-time delivery, order accuracy, inventory turnover, lead time, fill rate, customer satisfaction, and total landed cost. By regularly analyzing these metrics, businesses can identify areas for improvement, track progress, and make data-driven decisions to optimize their supply chain operations.

- How can supply chains improve customer service?

Improving customer service in supply chains involves understanding customer needs and expectations. By adopting customer-centric strategies, businesses can ensure quick and accurate order fulfillment, provide transparent and proactive communication, and offer personalized experiences. Leveraging technology, such as customer relationship management (CRM) systems and order tracking tools, can enhance visibility and enable better customer engagement. By continuously monitoring and enhancing customer service, businesses can build strong relationships and gain a competitive edge.

Remember, supply chains are dynamic and evolving, and it's crucial for businesses to continuously adapt, innovate, and align their practices with the changing market landscape to remain competitive.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.