Last Updated on April 11, 2024

Companies often outsource product assembly in order to streamline their operations, reduce costs, and increase efficiency. In recent years, Mexico has emerged as a top outsourcing destination.

In addition to its skilled workforce, favorable business climate, and proximity to the United States, Mexico offers a number of advantages to businesses looking to outsource their product assembly operations.

We will explore five key benefits of outsourcing product assembly to Mexico, as well as how they can benefit businesses in improving their bottom line, enhancing productivity, and achieving their goals.

Outsourcing Product Assembly to Mexico: What It Means

An organization that outsources product assembly to Mexico contracts with a third-party manufacturer in Mexico to manufacture, assemble, and package its products. Essentially, the business sends the necessary components or materials to a manufacturer in Mexico, where they are assembled into finished products according to its specifications.

Companies can reduce their production costs by outsourcing product assembly to Mexico while still maintaining high quality standards. As a result, businesses may be able to compete more effectively in the marketplace, while also freeing up resources that may be used for other purposes.

Access to Innovation

Mexico's burgeoning manufacturing sector is characterized by innovation and technological advancement. By establishing a presence in Mexico, companies gain access to cutting-edge technologies and industry best practices, fostering innovation and driving continuous improvement.

Companies can reduce their production costs by outsourcing product assembly to Mexico while still maintaining high quality standards. Share on XProduct Assembly in Mexico Benefit 1: Lower Labor Costs

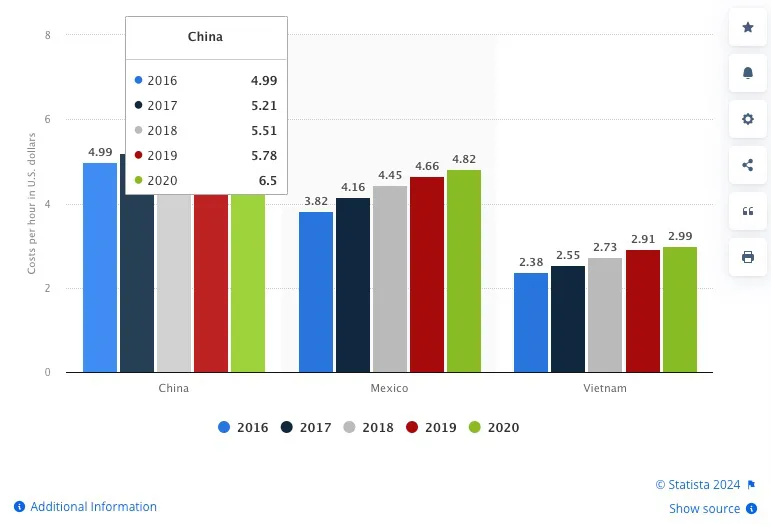

The cost of labor in Mexico is generally lower than in the United States. As of November 2023, the average hourly wage in Mexico's manufacturing industry is $4.00, compared with $20-25 in the United States. China also has higher labor rates than Mexico. The cost of manufacturing labor in China in 2020 is estimated to be $6.5 U.S. dollars per hour, according to China Briefing.

Source: Manufacturing labor costs per hour for China, Vietnam, Mexico from 2016 to 2020 https://www.statista.com/statistics/744071/manufacturing-labor-costs-per-hour-china-vietnam-mexico/

In spite of this, it is important to keep in mind that labor costs can vary significantly according to the type of work being performed and the location within each country. Certain regions of Mexico may have wages that are more comparable to those in the United States for highly skilled workers in certain industries such as automotive and aerospace. Furthermore, labor costs may be lower in some regions of the United States than in others.

Product Assembly in Mexico Benefit 2: Outsourcing to Mexico Can Lower Product Assembly Costs

Economies of Scale: Due to Mexico's well-developed manufacturing industry, the country has many suppliers and service providers. For businesses outsourcing to Mexico, this can result in economies of scale, thereby reducing the overall cost of production.

Lower Overhead Costs: It is also possible to reduce overhead costs, such as rent and utilities, by outsourcing product assembly to Mexico. The reason for this is that many Mexican manufacturing facilities offer lower rental rates and other costs than their American counterparts. According to Supply Chain Brain:

For the multinationals that do business in the red-hot U.S. economy, near-shoring often means northern Mexico, where labor costs are cheap, land is plentiful and the border is just a short ride away. El Paso, Texas, is less than 10 miles to the north of most of the new plants in Juarez.

Other border cities — Tijuana, along the west coast, and Reynosa, Matamoros and Piedras Negras, far to the east — are undergoing similar industrial booms, providing a much-needed lift to a Mexican economy that has been slow to recover from last year’s collapse.

Favorable Business Climate: To attract foreign investment, Mexico has implemented a number of policies and incentives, including tax incentives and streamlined regulations. The most important of these are Duty Referral Programs.

A deferral program is an authorisation provided by the Mexican Ministry of Economy to those companies importing raw materials or fixed assets to manufacture finished products within Mexico for export.

In addition to the benefits described for CIT purposes in the Income determination section, Maquiladoras under the IMMEX program are entitled to the following customs benefits:

No payment of import duties for temporarily imported raw materials, as long as they are exported.

Temporarily imported raw materials and fixed assets will not be subject to VAT when the Mexican entity importing the goods obtains a VAT certification (see VAT in the Other taxes section) from the tax authorities related to the adequate control of such imports or posts a bond guaranteeing the VAT payment until the goods are exported.

PWC

Quality Assurance: With stringent quality control measures in place, Mexico offers assurances of superior product quality. By adhering to international standards and implementing rigorous inspection protocols, manufacturers can uphold the highest quality standards and bolster brand reputation.

By outsourcing product assembly to Mexico, businesses are able to lower production costs while still maintaining high quality standards. Prior to making a decision to outsource, companies should carefully consider the costs and benefits of outsourcing, as well as work closely with their manufacturing partners to ensure quality control and other factors are considered.

Product Assembly in Mexico Benefit 3: Access to Skilled and Educated Labor

Mexico's workforce has a strong tradition of manufacturing and assembly, with an emphasis on the automotive, aerospace, electronics, and medical device industries. In this country, there is a large and growing pool of skilled workers who are trained in the latest manufacturing techniques and technologies.

Mexico's workforce has a strong tradition of manufacturing and assembly, with an emphasis on the automotive, aerospace, electronics, and medical device industries. Share on XAs part of its effort to develop a skilled workforce for its manufacturing industry, Mexico has made substantial investments in education and training programs. A number of technical and vocational schools in the country provide specialized training in engineering, machining, welding, and quality control. It is important to note that many of these schools have partnerships with local businesses and industry groups, which helps to ensure that their programs are aligned with the needs of the manufacturing industry.

Mexico has an excellent educational system that promotes the study of STEM subjects (science, technology, engineering, and mathematics). There has been substantial growth in their programs since the early 1990s, and the coursework is almost identical to that offered at universities in the United States.

Mexico has an excellent educational system that promotes the study of STEM subjects (science, technology, engineering, and mathematics). There has been substantial growth in their programs since the early 1990s, and the coursework is… Share on XAlmost twice as many engineers graduate from Mexico's universities every year as from Canada, Germany and Brazil, which is about half the size of Mexico.

Source: Statista https://www.statista.com/statistics/1026433/students-higher-education-mexico/

Universities in Mexico are collaborating with universities in the Ivy League in order to attract more Mexican students to their graduate programs. The Monterrey Institute of Tertiary Education and Technology (ITESM), Anahuac University, UNAM, and the Instituto Politecnico Nacional are some of Mexico's top universities.

Mexico is the 9th-largest country of origin for students studying in the United States. In the 2020–2021 academic year, 12,986 Mexican students were enrolled in U.S. schools, primarily in undergraduate programs due to the prestige of the American higher education system, as well as the strong ties and proximity between the countries.

International Trade Administration

In general, Mexican workers are known for their technical expertise, attention to detail, and commitment to quality. The country has become an attractive destination for businesses looking to outsource their manufacturing and assembly operations because of this. Business organizations can benefit from Mexico's lower labor costs and favorable business climate by working with skilled Mexican workers.

In general, Mexican workers are known for their technical expertise, attention to detail, and commitment to quality. Share on XCase Study: Schutt Sports

A Successful Cross-Border Hiring Model

Schutt Sports had to come up with a comprehensive solution to a pivotal challenge. Focusing on reconditioning and refurbishing football helmets streamlined the company's manufacturing operations. In addition to local high schools, prestigious college football programs, and even the NFL, this process serves a wide range of clients.

To address this challenge, Schutt Sports partnered with Novalink to reduce operational costs. This partnership will result in cost savings and improved efficiency in the refurbishment and assembly process. With the help of a reliable partner, Schutt hopes to enhance its competitive advantage and strengthen its position in the sports equipment market.

This collaboration was characterized by the establishment of a significant Mexican labor force. In order to meet fluctuating demands, the workforce was designed to be dynamic and scalable. To meet the increased workload during peak production periods, the labor force could be rapidly expanded. During slow periods, it could be downsized to maintain efficiency and cost-effectiveness.

Product Assembly in Mexico Benefit 4: Mexico's Skilled Labor Force Outshines Global Competitors

Mexico's labor force is often compared to that of China, another major player in global manufacturing, when it comes to direct comparisons. However, Mexico is closer to the United States, has a skilled workforce, and has a favorable business climate, which make it an attractive alternative to China.

In Latin America, Mexico is one of the largest manufacturing economies and has developed a well-established industrial infrastructure. This has helped to attract significant foreign investment, particularly in the automotive, aerospace, electronics, and medical device sectors.

In Latin America, Mexico is one of the largest manufacturing economies and has developed a well-established industrial infrastructure. Share on XIn comparison with many other countries in the region, Mexico has a more developed manufacturing industry, and has invested heavily in education and training programs to develop a skilled workforce. The low cost of manufacturing and assembly in Mexico has made it an attractive destination for businesses looking to outsource.

Mexico's economy has performed well relative to other major Latin American economies in recent years, largely because of its thriving manufacturing sector. Unlike Brazil and Argentina, whose manufacturing sectors are slumping, Mexico has continued to see solid growth because of its integration with and dependence on the U.S. market. Although low global oil prices will put pressure on Mexico's economy, the performance of the manufacturing sector — especially in high-end manufacturing — will be a key driver of Mexico's economic growth this year and beyond.

Forbes

Mexico may not have a large labor force as some other countries, but its skilled workforce, favorable business climate, and strategic location make it a global manufacturing player.

Mexico may not have a large labor force as some other countries, but its skilled workforce, favorable business climate, and strategic location make it a global manufacturing player. Share on XProduct Assembly in Mexico Benefit 5: Improved Supply Chain and Production Efficiency

The proximity of Mexico to the United States can help improve supply chain efficiency and reduce lead times. Outsourcing product assembly to Mexico allows companies to produce and assemble their products closer to target markets, resulting in shorter lead times and faster delivery.

Outsourcing product assembly to Mexico allows companies to produce and assemble their products closer to target markets, resulting in shorter lead times and faster delivery. Share on XMoving some or all supply to North America may boost profitability directly, while also increasing the flexibility and responsiveness of the supply chain. Considering the full cost cycle is vital in deciding whether targeted benefits can be achieved.

By relocating to Mexico, certain production lines in these industries may save 15 to 25 percent of total landed cost; and a facility in the United States may have a similar cost profile to an overseas hub, with closer proximity to end users. Given the total landed cost, there could be a strong case for regionalization.

McKinsey

Companies can easily source raw materials and components locally thanks to the country's established infrastructure and logistics network, which reduces the time and cost associated with importing materials from overseas. As a result, companies will be able to respond more quickly to changes in demand and reduce delivery lead times.

Operation Efficiency and Eliminating Waste

In the case of a product assembly operation, it is important to understand that it involves more than simply getting the components and assembling them; there is also a lot of analysis that goes into the flow of the assembly line and how to make it more efficient. The full picture of a Mexico manufacturing operation allows you to break it down to the smaller components and ensure that everything you add to the assembly process adds value to the product.

The common misconception is that buying a thousand pieces of X components will result in a thousand finished products. Usually, however, suppliers or vendors will incur some waste, and some will be generated by the execution process, which can be material or man-related. During production, new materials must be applied to ensure good quality.

This is where having a skilled and experienced manufacturing line comes into play and is important. A Mexico manufacturing operation might be the solution you are seeking.

It is important to have a skilled and experienced manufacturing line in this case. Manufacturing operations in Mexico might be the solution you're looking for. According to NovaLink’s Engineering and Information Systems Manager Manuel Campos:

Whether it is automatic electronic equipment or high power, industrial equipment, or the kind of IT-related things such as the assembling of computers, PCs, and main boards…Mexican labor is very skilled and able to adapt. Share on XFirst of all, the pool of talent in Mexico is very diverse in its skillset. There have been many industries established in Mexico for many years and the workers here have experience with many of them. Over the last 20 years there have been industries in Mexico that are not only labor intensive, but also have a technical aspect that has been proven to be well executed in Mexico. Whether it is automatic electronic equipment or high power, industrial equipment, or the kind of IT-related things such as the assembling of computers, PCs, and main boards…Mexican labor is very skilled and able to adapt. The pool of talent that we have at NovaLink, where most of the employees have more than 10 to 20 years working with the company, provides you a culture that is proven to produce results immediately.

Operational Flexibility

Mexico's favorable business environment and regulatory framework offer operational flexibility for companies seeking to adapt quickly to changing market conditions. This agility enables businesses to scale production efficiently and respond promptly to shifting consumer demands.

Conclusion: Outsourcing Product Assembly to Mexico Yields Growth and Enhanced Operations"

For companies looking to improve production efficiency and supply chain efficiency, outsourcing product assembly to Mexico offers numerous benefits. Due to its proximity to the United States, skilled labor force, and favorable business environment, Mexico is an ideal location for nearshoring.

In addition to accessing skilled workers and reducing production costs, outsourcing product assembly to Mexico also improves communication, streamlines logistics, and reduces lead times. Therefore, businesses are able to improve their bottom line, stay competitive, and meet customers' demands more effectively. In general, companies looking to expand their business and optimize their operations should consider Mexico's manufacturing industry.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.