Last Updated on July 9, 2025

Imagine this: you've poured your heart and soul into designing a game-changing product. It's unique, it solves a problem, and you just know it's going to blow the market wide open. But then, reality hits: manufacturing. Fear not, fellow innovators! There's a secret weapon in your arsenal: Custom Full-Service Manufacturing. From the benefits of custom full-service manufacturing to the strategic advantages of choosing Mexico as a manufacturing hub, this comprehensive guide aims to demystify the world of bespoke production.

Understanding Custom Full-Service Manufacturing

Custom full-service manufacturing is a bespoke approach to production, offering end-to-end solutions that cater to the specific requirements of businesses. Unlike traditional manufacturing processes, custom solutions involve tailoring every aspect, from design to production, to meet the client's exact specifications.

Custom manufacturing is the process of designing, engineering, and producing goods based on a customer's unique specifications, including build to order (BTO) parts, one-offs, short production runs, as well mass customization.

FormLabs

The Versatility of Custom Manufacturing

One of the key advantages of custom manufacturing is its versatility. Businesses can create products that precisely match their unique specifications, ensuring a perfect fit for their target market. This adaptability fosters innovation and allows companies to stay ahead in a competitive market.

The Role of Technology in Custom Manufacturing

Technology plays a pivotal role in custom full-service manufacturing. Advanced machinery and digital tools enable manufacturers to execute intricate designs with the utmost precision. This technological prowess not only enhances the quality of the products but also accelerates the production process.

What Value-Added Solutions Come with Total-Package Contract Manufacturing?

When you choose a full-service contract manufacturing partner, you’re signing up for a lot more than just product assembly. Think of it as hiring a backstage crew that handles everything, so you can take a confident bow in the spotlight. Here’s what you can typically expect under one roof:

Comprehensive Supply Chain Management

Forget drowning in supplier lists and endless emails! Full-service providers handle sourcing, purchasing, and vetting components through established networks—often leveraging bulk buying power to help you secure better prices and faster delivery times. They also manage compliance requirements (think RoHS, REACH, conflict minerals), ongoing quality checks, and material planning, leaving you free to focus on what matters most: your product and customers.

Precision Kitting & Inventory Handling

Ever tried assembling flat-pack furniture and realized halfway through that you’re missing a bolt? Top-tier contract manufacturers ensure that doesn’t happen—assembling kits with exactly the right parts, in the right quantities, ready for the production line. Keeping kitting and inventory within the same facility allows for speedy resolution if the rare hiccup occurs, minimizing downtime and helping you hit delivery targets.

Flexible Assembly Services

Whether you need a subassembly, a fully finished product, or just a one-off custom build, total-package providers have the tools and know-how. Advanced facilities—often equipped with cutting-edge tech like surface mount machines (à la FormLabs’ recommendations)—mean tighter quality control and less idle time moving materials from station to station.

Streamlined Fulfillment & Distribution

From climate-controlled warehousing to drop-shipping, cross-docking, and direct-to-consumer order fulfillment, these manufacturers manage logistics at scale. Whether you’re shipping to retail partners, eCommerce buyers, or right to the end-user’s door, they handle the details so your product gets where it needs to go, efficiently and cost-effectively.

Reverse Logistics & Aftermarket Services

Returns, repairs, and recycling aren’t just afterthoughts—they’re essential to your reputation and bottom line. Total-package partners can process returns (RMAs), repair products, recover valuable components, and manage environmental compliance, offering you true cradle-to-grave support.

The Full-Service Advantage

By integrating all these services, contract manufacturers offer truly scalable solutions—adapting to both small pilot runs and high-volume production alike. You’ll often have access to a dedicated program team, seamless order management, reliable warehousing, and the peace of mind that comes from not having to micromanage each step.

This kind of all-in-one partnership lets you focus on growing your business, while your manufacturing partner handles the heavy lifting behind the scenes.

Benefits of Opting for Custom Full-Service Manufacturing

- Tailored Solutions: One of the primary benefits is the delivery of tailored solutions. Businesses can create products that perfectly align with their brand image and meet the unique demands of their customer base.

- Cost Efficiency: Contrary to common misconceptions, custom manufacturing can be cost-effective. By eliminating unnecessary features and focusing on essential elements, businesses can optimize their production costs.

- Faster Time-to-Market: Custom manufacturing reduces the time-to-market for new products. The streamlined process allows for quicker prototyping and production, enabling businesses to respond swiftly to market demands.

There is a persistent myth in the manufacturing industry that custom work only comes at premium prices, and that spreading out manufacturing duties among low-cost vendors is always the most cost-effective way to get the job done.

In reality, custom manufacturing and engineering processes can actually save companies money while delivering higher-quality output. No matter how complex the job is, custom manufacturing helps remove risk, ensure organization, and make the design and production processes more efficient.

WHY “CUSTOM COSTS MORE” IS A MYTH IN MANUFACTURING

The Full-Service Advantage: More Than Just Production

Custom full-service manufacturing takes the hassle out of juggling multiple vendors by rolling everything—procurement, assembly, distribution, and even logistics—into one streamlined solution. Think of it as a one-stop shop for OEMs, where every step from sourcing materials to final delivery happens under one roof. This not only slashes capital investments and personnel costs, but also dramatically shortens lead times.

By consolidating supplier reviews, material resource planning, and compliance management (like RoHS and conflict minerals), businesses can focus on innovation instead of paperwork. Keeping the entire production cycle in a single facility means speedier detection and correction of rare mishaps, reducing supply chain disruptions and minimizing delivery risks.

Operational Perks Include:

- Climate-controlled warehousing and flexible dropship capabilities

- Efficient cross-docking and blind shipments

- Scalable fulfillment for eCommerce, direct-to-consumer, and retail orders

- Integrated reverse logistics for streamlined returns and customer support

This comprehensive approach doesn't just save money—it empowers companies to stay nimble, lean, and laser-focused on growth. By eliminating the friction of moving parts from kitting to assembly to distribution, custom full-service manufacturing offers a turnkey partnership that keeps your operations running like a well-oiled machine.

The Value of Full-Service Custom Manufacturing

Choosing a full-service partner means much more than just assembling components—it’s about integrating procurement, engineering, assembly, and even logistics into a single streamlined solution. This “one-stop shop” approach eliminates the need for juggling multiple vendors, reduces hidden operational costs, and minimizes supply chain headaches. By bundling everything under one roof, businesses can avoid the capital investments and staffing required to manage these activities internally.

Beyond cost efficiency, full-service custom manufacturing dramatically shortens lead times. When every stage of production—from sourcing to delivery—is coordinated by a single team, products move through the pipeline faster and with fewer hiccups. The result? Companies stay nimble and responsive, able to adapt quickly to changing market demands while maintaining a clear focus on their core business.

In essence, custom full-service manufacturing delivers the fullest value: it frees up resources, keeps operations lean, and empowers businesses to remain competitive without sacrificing quality or control.

Keeping OEMs Lean, Nimble, and Focused

Custom full-service manufacturing does more than just deliver bespoke products—it empowers original equipment manufacturers (OEMs) to focus on what they do best. By partnering with a full-service provider, OEMs can hand over the complexities of design, sourcing, production, and logistics. This single-source approach drastically reduces the need to juggle multiple vendors or manage overlapping supply chains.

With fewer operational headaches, OEMs can:

- Reallocate internal resources toward innovation, marketing, and core business development.

- Adapt quickly to shifts in customer demand, since a turnkey manufacturing partner can scale up or down as needed.

- Streamline production timelines, eliminating bottlenecks that often come from coordinating multiple outside suppliers.

- Maintain tighter quality control, since fewer steps are outsourced to disparate entities.

Ultimately, this streamlined setup allows OEMs to run a more agile, focused operation—making it easier to seize new opportunities, reduce overhead, and consistently deliver high-quality products to market.

The Power of Integration: Kitting, Assembly, and Distribution Under One Roof

A major advantage of custom full-service manufacturing is the seamless integration of kitting, assembly, and distribution within a single facility. This holistic setup eliminates the need to shuffle parts and finished goods between multiple locations—a logistical headache that often leads to unexpected delays, mishandled products, and added costs.

When everything—from sourcing components and kitting them together, to assembling finished products and shipping them out—happens under one roof, businesses benefit in several ways:

- Reduced Risk & Faster Corrections: Issues are spotted and resolved quickly since all stages of the process are in close proximity, which means fewer surprises and smoother quality control.

- Lower Operating Costs: By cutting out transportation between various facilities, companies save on time, fuel, and labor. These savings can be passed directly to the customer.

- Streamlined Communication: With every team and process housed together, coordination becomes more efficient, reducing the chance of mistakes and bottlenecks.

- Flexible Fulfillment Options: Many full-service manufacturers offer climate-controlled storage, direct-to-customer shipping, cross-docking, and even blind shipments. This allows for a truly turnkey approach—just as easily handling large B2B orders as single-unit eCommerce fulfillment.

Ultimately, the one-stop-shop environment keeps supply chains nimble and responsive—helping businesses stay competitive and deliver reliably to their customers.

Mexico as a Hub for Custom Full-Service Manufacturing

- Proximity to the U.S.: Mexico's strategic geographical location makes it an ideal destination for custom manufacturing, especially for U.S.-based businesses. Proximity reduces shipping costs and ensures timely deliveries.

- Skilled Workforce: Mexico boasts a skilled workforce with expertise in various industries. This pool of talent ensures that businesses receive high-quality custom manufacturing services.

- Cost-Effective Labor: Compared to many Western countries, Mexico offers cost-effective labor without compromising on quality. This cost advantage makes it an attractive destination for custom manufacturing.

Breaking Down Perplexities in Custom Manufacturing

The world of custom full-service manufacturing can be perplexing. However, breaking down complex processes into simpler components helps businesses navigate the intricacies of customization with ease.

Custom full-service manufacturing encompasses a wide array of processes, from design and prototyping to production, logistics, and distribution. Each of these stages involves a multitude of variables and considerations.

To demystify these complexities, it’s helpful to break down the essential components that make up a full-service manufacturing bundle:

Key Components of Custom Full-Service Manufacturing

Supply Chain Management

A robust supplier network is at the heart of efficient custom manufacturing. Full-service manufacturers handle everything from sourcing new parts and negotiating pricing, to managing lead times and ensuring compliance with regulations like RoHS and conflict minerals directives. By assuming responsibility for supplier qualification, first article inspections, and ongoing material resource planning, these providers save businesses both time and overhead.

Kitting

Once components arrive, precision is vital. Kitting involves assembling exact quantities of specific parts from inventory and preparing them for the assembly line. Accurate kitting not only streamlines production but also minimizes the risk of inventory errors and bottlenecks that can slow down the entire process.

Assembly

Full-service providers can handle complete product assembly, not just subassemblies. Because all stages—from kitting to assembly—take place under one roof, there are fewer transportation costs and delays. This seamless integration means issues can be identified and resolved quickly, ensuring consistent quality and timely delivery.

Fulfillment and Distribution

Distribution is more than just shipping products. Full-service manufacturers often offer climate-controlled warehousing, dropshipping, and cross-docking capabilities. They support fulfillment for eCommerce, retail, and direct-to-consumer channels, providing scalable solutions that adapt to business needs.

Reverse Logistics

Support doesn’t end after delivery. Full-service manufacturing can include reverse logistics—handling returns, repairs, maintenance, and even reclaiming usable components from scrapped units. Leveraging existing manufacturing skills and facilities, these services offer an added layer of support and value.

By managing these interconnected stages in-house, custom manufacturers reduce risk, improve organization, and drive efficiency throughout the production lifecycle. This comprehensive approach not only simplifies the journey from concept to delivery but also helps businesses achieve higher quality outcomes—often at a lower total cost.

Navigating Warehousing, Dropshipping, and Order Fulfillment

Custom full-service manufacturers offer far more than fabrication—they seamlessly manage the entire fulfillment chain. By integrating climate-controlled warehousing, they safeguard sensitive products and ensure inventory is always ready when needed. Dropshipping services allow manufacturers to ship products directly from the warehouse to the end customer, cutting down transit times and streamlining logistics for eCommerce and retail operations.

Cross-docking is another tool in their arsenal, where incoming goods are swiftly transferred from receiving to outbound shipping with minimal storage, speeding up the journey from manufacturer to consumer. For those seeking discretion, blind shipping is utilized; here, the manufacturer ships products to customers without revealing the original vendor’s identity, preserving brand relationships and confidentiality.

Collectively, these services help OEMs scale their distribution processes efficiently, keep costs competitive, and ensure orders—whether B2B, D2C, or bulk retail—reach their destination promptly and professionally.

Why Outsourcing Reverse Logistics Makes Sense for OEMs

Reverse logistics—that is, managing product returns, repairs, and refurbishment—can be a complex and resource-intensive aspect of manufacturing. For original equipment manufacturers (OEMs), partnering with a full-service contract manufacturer offers distinct advantages in this arena.

First, contract manufacturers are already equipped with the advanced diagnostic tools, dedicated floor space, and qualified technical staff needed to handle returns, repairs, and the extraction of reusable parts. This infrastructure, which is essential for high-quality manufacturing, doubles perfectly for streamlined reverse logistics processes.

By outsourcing these services, OEMs can:

- Reduce Operational Burdens: Free up their own workforce and facilities for core competencies, rather than devoting resources to returns processing and repair.

- Boost Cost Efficiency: Lower overall costs by leveraging the contract manufacturer’s economies of scale, instead of investing in specialized equipment or extra personnel.

- Enhance Customer Satisfaction: Benefit from faster turnaround times and organized handling of returns and repairs, resulting in a smoother experience for end users.

- Maximize Resource Recovery: Improve profits by salvaging usable components and subassemblies from scrapped units, turning potential waste into valuable inventory.

In essence, since the skillsets and technologies required for reverse logistics closely mirror those used in production, OEMs that tap into their contract manufacturer’s expertise enjoy simplified operations, improved quality, and measurable savings.

The Role of Reverse Logistics in Custom Manufacturing

An often-overlooked aspect of full-service manufacturing is reverse logistics—a process that focuses on what happens when products are returned after reaching the customer. Rather than being limited to manufacturing alone, experienced contract manufacturers extend their expertise to handle returns, repairs, and the recovery of valuable components.

Reverse logistics covers several key activities:

- Managing Returns: Handling the return process efficiently, including issuing and tracking return material authorizations (RMAs) to ensure product accountability and customer satisfaction.

- Product Repairs and Maintenance: Diagnosing, repairing, and maintaining returned items using the same skilled technicians, specialized equipment, and manufacturing space that are integral to initial production.

- Component and Material Recovery: Extracting usable parts, subassemblies, or raw materials from products that cannot be resold or repaired, thereby reducing waste and maximizing resource use.

By integrating these reverse logistics operations within their core services, custom manufacturers can provide seamless support that stretches far beyond the assembly line. This holistic approach not only helps reduce costs but also enhances sustainability and keeps valuable resources in circulation—a win-win for both manufacturers and their clients.

Exploring Assembly Capabilities in Full-Service Contract Manufacturing

Full-service contract manufacturers bring a comprehensive suite of assembly options to the table, going well beyond standard subassembly production. These providers can handle everything from building individual components to executing complete product assembly under one roof. This integrated approach not only streamlines production but also eliminates the added costs and logistics of moving materials between multiple sites—whether it's from kitting to assembly or on to distribution.

For example, many full-service manufacturers utilize cutting-edge technologies like advanced surface mount technology (SMT) for printed circuit board assembly, a crucial capability for electronics and tech products. With this expertise, manufacturers can support a range of industries, ensuring precise, reliable assembly across automotive, medical devices, consumer products, and more.

By centralizing the entire assembly process, businesses benefit from:

- Consolidated logistics: Fewer touchpoints mean less risk of delays and errors.

- Cost efficiencies: Reduced transportation and handling requirements drive down expenses.

- Quality assurance: Centralized control fosters greater oversight and uniformity in finished products.

In short, full-service contract manufacturers empower businesses to bring their ideas to life with cohesive, high-quality assembly solutions—all while keeping timelines tight and costs in check.

Managing Supplier Networks and Compliance

A hallmark of full-service contract manufacturers is their ability to expertly manage vast supplier networks and ensure rigorous compliance with industry standards. Rather than starting from scratch, these manufacturers leverage well-established, pre-vetted relationships with reliable suppliers. This not only streamlines the sourcing of new parts but also enables the negotiation of competitive pricing and reduction of lead times for critical components.

The benefits go beyond sourcing efficiency. Contract manufacturers take on the responsibility for essential—and often time-consuming—activities such as vetting and qualifying suppliers, performing first article inspections, and executing ongoing material resource planning (MRP). They are also adept at navigating regulatory requirements, including conflict minerals tracking and RoHS (Restriction of Hazardous Substances) compliance management, relieving businesses from these intricate and ever-evolving obligations.

By entrusting these processes to a partner with robust systems already in place, companies free themselves from significant overhead costs and administrative complexities, allowing them to focus on innovation and growth. This transfer of supply chain intricacy not only mitigates risk but also ensures that the end products adhere to both client expectations and international standards.

Understanding Kitting in Contract Manufacturing

Kitting is a crucial step in the contract manufacturing process that involves gathering and organizing all the necessary individual parts and components required for assembly. Think of it as creating a "ready-to-go" package for each production order—each kit contains the exact items and quantities needed to assemble the finished product on the line.

Why does this matter? Accuracy in kitting is fundamental. Incorrect components or missing pieces can halt production and create ripple effects throughout inventory management and scheduling. By ensuring that the right parts are bundled together from the start, manufacturers minimize delays and reduce the likelihood of inventory errors.

A major advantage of working with a full-service contract manufacturer is that every stage, from inventory picking to final assembly, is often handled under one roof. This allows for tighter coordination, prompt identification of any discrepancies, and rapid resolution—keeping the entire supply chain running smoothly and reducing the risk of missing critical delivery deadlines.

Defining Requirements

At the outset, businesses can start by clearly defining their customization requirements. This involves a detailed understanding of the specific features, dimensions, materials, and functionalities desired for the end product. By articulating these customization parameters, businesses lay the foundation for a more focused and streamlined manufacturing process.

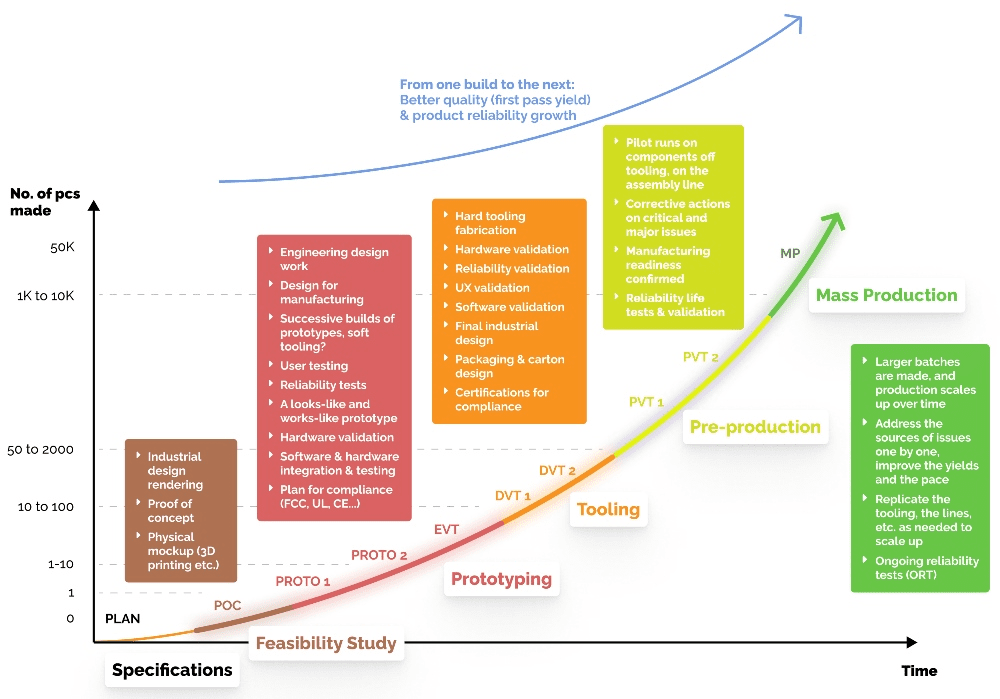

Source: SoFeast: How Many Prototypes Are Needed Before We Get ‘Perfection?’

Breaking Down the Production Process

The next step involves breaking down the production process itself. This can be achieved by dividing the manufacturing journey into distinct phases, such as design, prototyping, testing, and final production. Each phase can then be addressed independently, allowing businesses to concentrate on specific aspects without feeling overwhelmed by the entire process.

Moreover, breaking down customization into simpler components involves leveraging technology and specialized tools. Computer-aided design (CAD) software, for instance, can simplify the design process, providing a visual representation of the customized product and facilitating efficient collaboration between designers and manufacturers. Similarly, prototyping tools and virtual simulations can streamline the testing and validation stages.

Streamlining Supply Chain Management

In the logistics and distribution aspects of custom manufacturing, breaking down complexity means segmenting the supply chain into manageable steps. From sourcing raw materials to the final delivery of the customized product, businesses can optimize each stage individually, ensuring a seamless and efficient flow of materials and goods.

A critical part of this process involves managing supplier relationships and overseeing the acquisition of components. By working with a vetted network of suppliers, businesses can source new parts more efficiently, negotiate better pricing, and reduce lead times. This approach also helps minimize overhead related to activities such as supplier qualification, first article inspection, material resource planning (MRP), and compliance with regulations like RoHS and conflict minerals requirements.

By treating each supply chain and compliance task as its own distinct step, companies avoid becoming overwhelmed and gain greater visibility and control. Breaking these responsibilities into manageable pieces empowers teams to address challenges proactively, allocate resources wisely, and ensure that every link in the chain supports both quality and customization goals.

Fulfillment and Distribution Services

A key advantage of partnering with full-service contract manufacturers is their extensive suite of fulfillment and distribution options. These firms streamline the journey from production line to customer doorstep with a combination of modern logistics solutions:

- Climate-Controlled Warehousing: Products are stored in environments optimized for temperature and humidity, ensuring quality and integrity for everything from electronics to food-grade goods.

- Flexible Shipping Methods: Whether you need direct delivery to retailers, eCommerce customers, or a network of distributors, these manufacturers offer adaptable solutions like dropshipping, cross-docking, and blind shipments. This flexibility helps businesses meet a variety of delivery requirements without added complexity.

- Order Fulfillment Management: By leveraging advanced inventory systems, manufacturers can handle picking, packing, and shipping for both bulk orders and individual customer shipments. This includes managing retail, direct-to-consumer, and wholesale fulfillment—freeing up your resources and ensuring orders arrive promptly.

- Scalable Distribution: With in-house logistics infrastructure, full-service manufacturers can seamlessly scale fulfillment capacity as your business grows. Whether you're ramping up for a seasonal spike or managing steady long-term demand, you benefit from efficient and cost-effective distribution.

By integrating these services, companies can simplify supply chain management and maintain a competitive edge, all while ensuring products reach their customers efficiently and reliably.

Ensuring Accuracy and Minimizing Bottlenecks in Kitting

Accuracy and efficiency are crucial when it comes to kitting—the process where individual components are gathered and assembled into kits for the production line. Full-service contract manufacturers excel at keeping this process on track in several key ways.

First, by operating under one roof, every stage— from parts receiving to kitting— is closely coordinated. Components are carefully checked, counted, and organized in dedicated inventory systems. Using advanced tools like barcode scanners and inventory management software helps eliminate errors in selecting the right parts and quantities for each kit.

When everything happens in the same facility, any discrepancies—say, a missing part or a mix-up in component counts—are quickly identified and corrected. This proximity also means teams can address issues on the spot, reducing potential production slowdowns and helping to keep projects on schedule. Streamlined communication between inventory, production, and quality control teams further ensures that kits are assembled accurately and get to the assembly line exactly when needed.

Ultimately, this coordinated, hands-on approach means fewer disruptions, more reliable delivery timelines, and a smoother overall manufacturing process.

Conclusion

In conclusion, custom full-service manufacturing is not just a production method; it's a strategic approach that empowers businesses to thrive in a competitive landscape. Choosing Mexico as a manufacturing hub adds another layer of advantage, combining cost-effectiveness with skilled craftsmanship.

FAQs About Custom Full-Service Manufacturing

Q1: Is custom manufacturing suitable for small businesses?

Absolutely! Custom manufacturing can be tailored to accommodate the production needs of small businesses, offering flexibility in scale and cost.

Q2: How does custom manufacturing impact product quality?

Custom manufacturing often enhances product quality as each item is meticulously crafted to meet specific standards and requirements.

Q3: Are there any limitations to custom manufacturing?

While custom manufacturing offers unparalleled flexibility, certain limitations may arise in terms of production scale and cost-effectiveness for mass production.

Q4: Can I use my existing designs in custom manufacturing?

Certainly! Custom manufacturing often involves adapting existing designs to meet specific requirements, ensuring a perfect match to your vision.

Q5: What are the key considerations when choosing a custom manufacturing partner?

Key considerations include the partner's expertise, technological capabilities, production capacity, and track record in delivering custom solutions.

In the dynamic landscape of manufacturing, embracing custom full-service solutions is not just a strategic choice—it's a necessity. By unlocking the potential of bespoke production, businesses can stay ahead of the curve and meet the ever-evolving demands of their markets.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Expand your knowledge and delve deeper into more information about full service manufacturing in Mexico with our curated collection of related blog posts.

- Stop Waiting: Mexico Product Manufacturing Is Ready When You Are

- Why Factories in Mexico Are the Preferred Choice for Nearshoring

- 5 Easy Steps to Move Your Production to a Mexican Factory

- Turnkey Manufacturing vs. Traditional Manufacturing: Which Is Better for Your Business in Mexico?

- Customer Service in Mexico Manufacturing: A Key to Success