Last Updated on June 26, 2024

Global manufacturing is evolving rapidly, and companies are strategically reassessing their production hubs to gain a competitive edge. This change has been exemplified by numerous businesses shifting manufacturing from China to Mexico. In this comprehensive guide, we delve into the immediate benefits of such a move and why it positions your business for success.

Understanding the Current Manufacturing Landscape

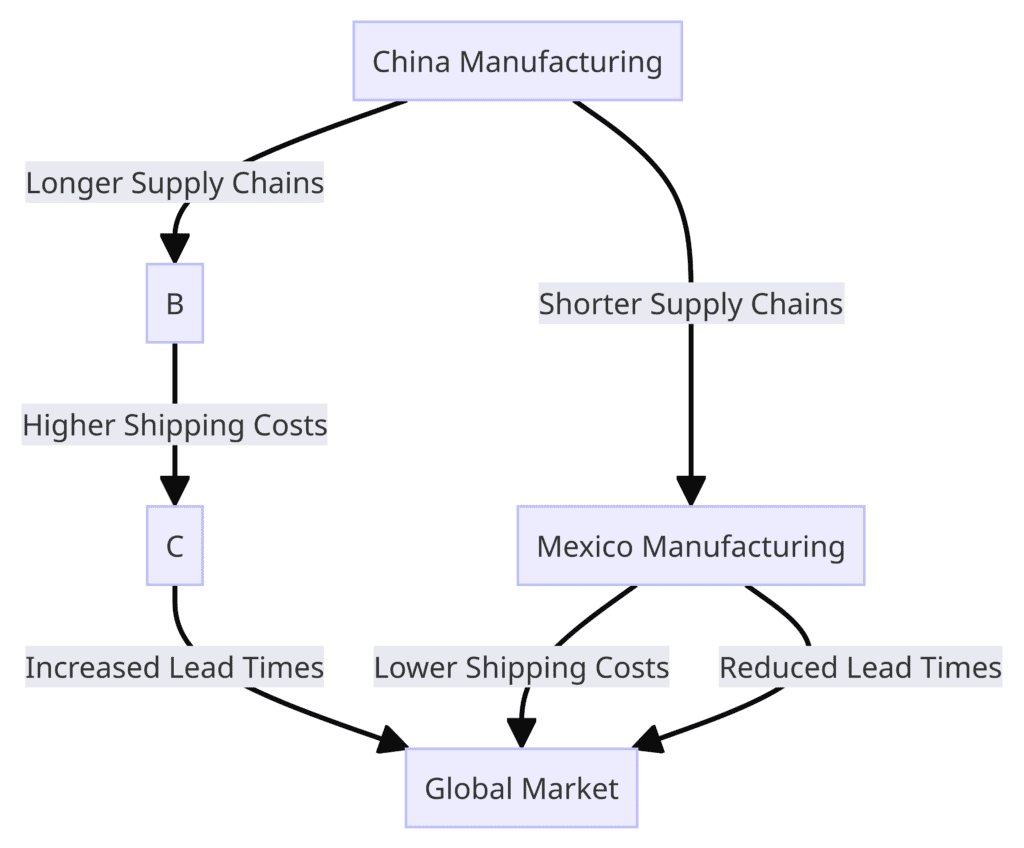

The worldwide manufacturing industry is undergoing a significant transformation characterized by shifts in economic landscapes and geopolitical factors. Faced with these dynamic challenges, companies are strategically evaluating their manufacturing strategies. In this context, a notable trend is emerging – the decision to relocate manufacturing operations from China to Mexico is gaining prominence as a practical and viable solution.

This strategic move is likely influenced by several factors. First and foremost, companies may be responding to evolving economic conditions, such as rising labor costs and changing trade dynamics in China. Additionally, geopolitical considerations, including trade tensions and uncertainties, could prompt businesses to reassess the location of their manufacturing operations

By shifting manufacturing operations to Mexico, companies aim to adapt to the evolving global landscape. They also aim to mitigate geopolitical uncertainties risks, and optimize production processes. This strategic decision reflects a dynamic response to the challenges posed by the changing dynamics of the global manufacturing sector.

While a general global demand slowdown, weakening consumer demands for goods and retreating business inventory growth contribute to the decline in Chinese exports, a closer examination of the export data suggests another significant factor.

Furthermore, the disruptions caused by the COVID-19 pandemic and the ongoing conflict in Ukraine, combined with efforts to reduce dependency on China, have led to the emergence of the 'nearshoring' phenomenon, impacting global supply chains.

Shifting trade dynamics: Is China losing advantage to ‘nearshoring’?

Immediate Cost Savings from Mexico

Labor Cost Savings

One of the primary advantages of transitioning manufacturing to Mexico is the substantial reduction in labor costs. Skilled and semi-skilled labor in Mexico is competitively priced compared to Chinese counterparts. This shift enhances cost-efficiency and ensures high-quality production standards.

Operational overheads

Beyond labor, Mexico offers cost-effective operational overheads. From utility expenses to regulatory compliance, businesses find a more favorable economic environment that directly impacts their bottom line:

- Lower rent and land costs: Commercial real estate and land prices in Mexico are generally more affordable than in many developed countries, leading to lower overhead costs for facilities and operations.

- Developed infrastructure: While there are areas for improvement, Mexico has a well-developed infrastructure for transportation, logistics, and utilities, supporting efficient operations.

Proximity to Key Markets

North American Market Access

Strategic relocation to Mexico provides unparalleled access to the North American market. With a shared border with the United States, businesses can streamline supply chains, reduce shipping times, and respond more efficiently to market demands.

Trade Agreement Benefits

Mexico's participation in trade agreements like the United States-Mexico-Canada Agreement (USMCA) facilitates smooth cross-border trade. This minimizes trade barriers and fosters a conducive environment for international business operations.

Enhanced Agility and Flexibility

Faster Response to Shifting Preferences

- Reduced Lead Times: Proximity to the US market significantly cuts down transportation times, allowing companies to respond quickly to changes in consumer demand or emerging trends. Imagine needing a crucial component for a hot-selling gadget; instead of waiting weeks for shipments from Asia, a Mexican plant can deliver it in days.

- Agile Production Lines: Many Mexican facilities are geared to small batch production and rapid product modifications. This means you can adjust your offerings based on real-time market feedback, keeping ahead of the competition. Think limited-edition sneakers or seasonal variations on a popular product – Mexico makes it nimble and cost-effective.

Embracing Customization and Personalization

- Skilled Workforce: Mexico boasts a large pool of skilled manufacturing workers proficient in various techniques and technologies. This allows companies to offer customized products at scale, catering to individual preferences and niche markets. Picture personalized apparel or furniture – Mexican expertise makes it feasible without skyrocketing costs.

- Modular Production Systems: Many Mexican factories utilize modular production systems, enabling quick reconfiguration of assembly lines for different product variations. This empowers companies to introduce updated product features or even entirely brand-new lines rapidly, meeting specific customer demands and staying ahead of the curve.

Enhanced Supply Chain Agility

- Diversification: Manufacturing in Mexico reduces reliance on single-source suppliers and fragile global supply chains. This diversification mitigates risks associated with disruptions in distant countries, allowing companies to adapt and source materials or components more readily. Imagine a parts shortage in China throwing your production off track; Mexico offers an alternative within reach.

- Vertical Integration: Some companies even opt for vertical integration in Mexico, controlling various stages of production within the country. This further tightens control over response times and quality, making the entire process more agile and adaptable to changing circumstances.

Conclusion: Seizing the Advantages Offered by Mexico's Manufacturing Landscape

Overall, Mexico's manufacturing environment empowers businesses with the flexibility to adjust production based on consumer preferences, industry trends, and unforeseen challenges. This translates to a competitive advantage in a dynamic marketplace, allowing companies to innovate faster, cater to diverse needs, and stay ahead of the pack. Remember, in today's fast-paced world, agility is king, and Mexico provides the tools to wear that crown.

FAQ's on Shifting Manufacturing from China to Mexico

1. How can shifting manufacturing from China to Mexico provide a competitive advantage?

Shifting manufacturing from China to Mexico offers several advantages, including reduced labor costs, proximity to the North American market, and favorable trade agreements such as the USMCA. These factors contribute to cost savings, faster time-to-market, and increased flexibility in responding to market demands.

2. What are the key cost-saving benefits of relocating manufacturing operations to Mexico?

Mexico offers lower labor costs compared to China, making it an attractive destination for companies looking to reduce production expenses. Additionally, decreased shipping and logistics costs, along with favorable currency exchange rates, contribute to overall cost savings, positively impacting the bottom line for businesses.

3. How does proximity to the North American market enhance competitiveness?

Shifting manufacturing to Mexico brings companies closer to the lucrative North American market. This proximity reduces shipping times and costs, allowing businesses to respond more swiftly to customer demands. Faster delivery times enhance customer satisfaction and contribute to a competitive edge in the market.

4. What role do favorable trade agreements, such as the USMCA, play in gaining a competitive advantage?

Mexico's participation in trade agreements like the United States-Mexico-Canada Agreement (USMCA) facilitates seamless cross-border trade. Reduced tariffs and streamlined customs procedures contribute to cost-effectiveness and efficiency, enabling companies to navigate international trade barriers more effectively than in other manufacturing locations.

5. How does relocating manufacturing to Mexico impact supply chain resilience?

Diversifying manufacturing locations by shifting operations to Mexico can enhance supply chain resilience. This strategy mitigates risks associated with overreliance on a single location, providing companies with greater flexibility to adapt to unforeseen disruptions, geopolitical changes, or global economic shifts, ultimately bolstering overall competitiveness.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.