Last Updated on February 26, 2024

The winds of change are blowing through the manufacturing landscape. For decades, companies chased lower production costs overseas, often to China. But the tide is turning. Reshoring manufacturing to Mexico is gaining momentum, driven by a confluence of factors that make it a compelling proposition for businesses seeking agility, resilience, and growth.

Understanding Reshoring Manufacturing to Mexico

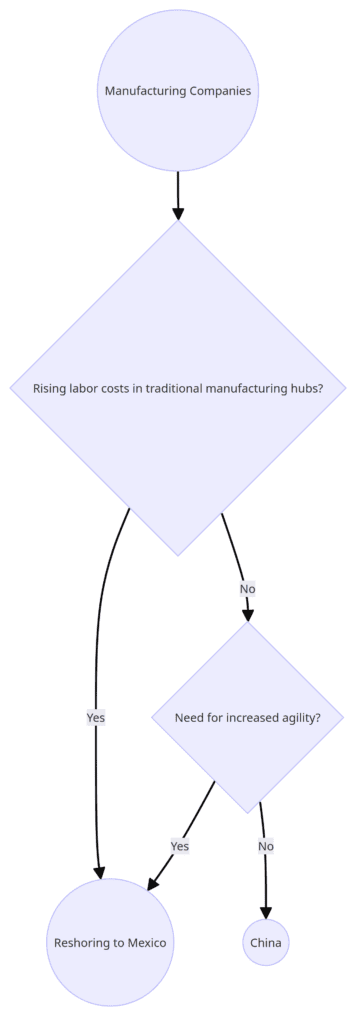

Reshoring manufacturing to Mexico involves the relocation of production facilities from overseas destinations back to Mexico. This strategic shift is driven by various factors, including rising labor costs in traditional manufacturing hubs, such as China. In addition, it is driven by the need for increased agility in responding to market demands. By bringing production closer to home, companies can reduce lead times, mitigate supply chain risks, and achieve cost efficiencies.

Why Mexico For Reshoring Manufacturing?

Imagine Mexico as the missing piece of the puzzle, strategically located in North America. It boasts a young, skilled workforce, competitive labor costs, and a robust trade infrastructure. Time zones are similar, facilitating communication and collaboration. Plus, the United States-Mexico-Canada Agreement (USMCA) ensures duty-free trade between the three nations, further streamlining operations.

How Does Reshoring Manufacturing to Mexico Fuel North American Manufacturing?

Think of reshoring to Mexico as an engine reboot. It injects new life into North American manufacturing, creating a more robust and regionally integrated ecosystem. Here's how it fuels success:

- Enhanced Agility: Proximity to your customer base means quicker response times and the ability to adapt to changing market demands swiftly. Imagine adjusting production volumes or introducing new product lines without overseas operations.

- Reduced Costs: While labor costs in Mexico may be slightly higher than in some Asian countries, the overall landed cost of goods (including transportation, duties, and logistics) is often lower due to geographical proximity. This translates into improved margins and competitiveness.

- Improved Quality and Control: Having your production closer to home allows for tighter quality control and faster issue resolution. Imagine visiting your manufacturing facility, collaborating with teams on the ground, and ensuring your products meet your exacting standards.

- Strengthened Supply Chains: Reshoring to Mexico fosters regional interdependence and reduces reliance on single-source suppliers. This diversification mitigates risks associated with geopolitical instability or natural disasters that can disrupt overseas production.

- Technology and Innovation: Mexico has invested in technology and innovation hubs, fostering collaboration between industry and academia. Access to technology and innovation ecosystems can drive advancements in manufacturing processes, product design, and efficiency, ultimately enhancing North American manufacturers' competitiveness.

- Market Integration: By reshoring manufacturing to Mexico, companies can take advantage of the integrated North American market facilitated by trade agreements like the USMCA. This integration enables streamlined trade processes, tariff benefits, and access to a combined consumer base of over 490 million people across the United States, Mexico, and Canada.

Reshoring Manufacturing to Mexico Isn't a One-Size-Fits-All Solution

Carefully evaluate your specific needs, production requirements, and target markets. Consider factors like product complexity, volume, and required skill sets. Partner with experienced logistics providers and leverage government incentives to make the transition smooth and successful.

Reshoring decisions require a comprehensive evaluation of multiple factors beyond labor and material costs. Organizations should conduct a total cost analysis, assess the advantages of proximity to the market, consider IP protection, and address local regulations and compliance requirements.

ThomastNet

Navigating Challenges and Opportunities

While reshoring manufacturing to Mexico presents compelling opportunities, it also poses challenges that companies must navigate effectively. These include managing geopolitical risks, optimizing supply chain logistics, and addressing regulatory complexities. By leveraging advanced technologies, fostering strategic partnerships, and investing in workforce development, companies can mitigate these challenges and capitalize on the advantages of manufacturing in Mexico.

Conclusion: Strategic Positioning for the Future

Remember, reshoring to Mexico isn't just about cost savings; it's about strategic positioning for the future. It's about building a more resilient, agile, and competitive manufacturing base in North America. So, if you're looking to reboot your engine and drive your business forward, consider Mexico as your strategic partner in growth.

Reshoring Manufacturing to Mexico FAQs:

1. What are the biggest challenges of reshoring to Mexico?

Navigating the logistics of moving production, adapting to a new cultural environment, and ensuring talent availability are some potential hurdles. However, with careful planning and the right partners, these challenges can be overcome.

2. What industries are best suited for reshoring to Mexico?

Labor-intensive industries like apparel, automotive, and electronics can benefit significantly from reshoring. Additionally, industries with complex supply chains or requiring frequent product updates can leverage Mexico's proximity to their North American markets.

3. What are the government incentives available for reshoring to Mexico?

Several programs exist to support companies reshoring to Mexico, including tax breaks, infrastructure development grants, and workforce training initiatives.

4. How can I find the right manufacturing partner in Mexico?

Industry associations, government agencies, and logistics providers can connect you with reputable manufacturers in Mexico that align with your specific needs.

5. What are the long-term benefits of reshoring to Mexico?

By reshoring, you gain greater control over your supply chain, improve product quality, enhance agility, and tap into a skilled and growing workforce. This translates to long-term cost savings, increased competitiveness, and sustainable growth for your business.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about reshoring to Mexico with our curated collection of related blog posts.

- Can Moving Manufacturing to Mexico Really Be Turnkey? Here’s What You Need to Know

- What Type of Company Should Not Move to Mexico?

- Stop Waiting: Mexico Product Manufacturing Is Ready When You Are

- 3 Hidden Costs You’re Avoiding by Manufacturing in Mexico (And Why It Matters)

- What Your CFO Needs to See Before Approving a Move: Why Moving Manufacturing from China to Mexico Makes Dollars and Sense