Last Updated on November 5, 2024

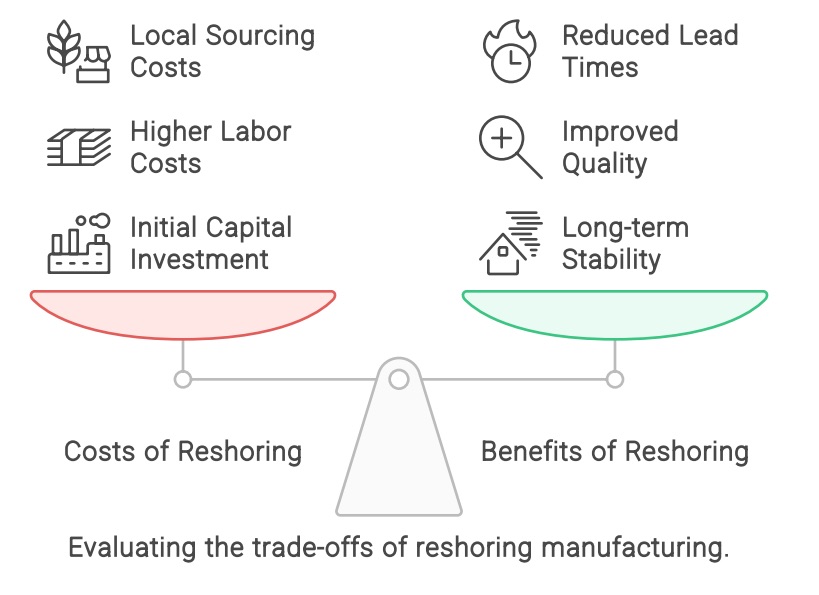

As companies weigh their options for manufacturing locations, many are considering reshoring – the process of bringing manufacturing back to their home country. But is it worth the switch? In this article, we'll delve into the cost-benefit analysis of reshoring manufacturing and explore how partnering with a nearshore manufacturing partner in Mexico, like NovaLink, can impact the decision.

Understanding Reshoring Costs

Before reshoring manufacturing, it's crucial to understand the costs involved. Reshoring is not merely about moving production back home; it involves a complex interplay of financial, logistical, and operational factors.

Initial Capital Investment

One of the most significant costs associated with reshoring is initial capital investment. This may include setting up updated facilities, purchasing equipment, and hiring skilled labor. While these upfront costs can be substantial, they are necessary to establish a stable and efficient manufacturing base.

Labor Costs

Labor costs in the home country are typically higher than offshore locations. However, the gap has narrowed, especially in countries like China, where wages have increased steadily. Reshoring to a country with a higher cost of living will increase payroll expenses. However, the trade-off often comes in the form of improved quality and better production control.

Supply Chain Adjustments

Reshoring also requires supply chain adjustments. Companies may need to source raw materials locally, which could be more expensive than offshore counterparts. However, this adjustment could reduce lead times and improve the reliability of the supply chain, thereby mitigating risks associated with delays and disruptions.

A report by Michael Zezas, Morgan Stanley's head of U.S. Public Policy Research and Municipal Credit Strategy, found that 42% of Morgan Stanley sector analysts believe the industries they cover need to secure supply chains faster than other industries. Furthermore, 58% of management teams at their covered companies are only somewhat—or not at all—receptive to such changes. Only 4% of North American management teams are highly receptive. - Morgan Stanley

Reshoring's Long-Term Benefits

While the initial costs of reshoring can be daunting, the long-term benefits often outweigh these expenses, leading to a more sustainable and resilient business model.

Improved Quality Control

One of the primary benefits of reshoring is enhanced quality control. When manufacturing is closer to a home base, it becomes easier to oversee production processes and maintain high standards. This proximity allows for quicker responses to quality issues, which is crucial for customer satisfaction and brand reputation.

Reduced Lead Times

Reshoring manufacturing significantly reduces lead times, as goods no longer need to be shipped from distant locations. This reduction not only speeds up delivery but also enables companies to be more responsive to market demands. In an era where consumers expect rapid service, shorter lead times can provide a competitive edge.

Increased Customer Trust

Consumers favor locally made products. Reshoring can improve a company's image and boost customer trust. By promoting local manufacturing, companies can tap into this growing preference, potentially increasing market share and customer loyalty.

Although there are numerous reasons to appreciate traditionally made products such as handmade goods and artisanal foods, we found that people also value how these products are made because they view traditional production as a form of cultural preservation. Since producers who use traditional methods only see a boost in consumer attitude when they're viewed as being motivated by cultural preservation, it is important for brands that use traditional production to convey authenticity so that consumers perceive their motives as pure. - SPSP.Org

Economic Contributions

By bringing manufacturing jobs back home, companies contribute to the local economy. This move can create jobs, support local suppliers, and stimulate economic growth, which leads to long-term benefits for the broader community.

Partnering with a Nearshore Manufacturing Partner in Mexico

Partnering with a nearshore manufacturing partner in Mexico can be a strategic way to offset the initial capital investments required when reshoring manufacturing back to North America. Here’s how this partnership can alleviate some of those costs:

Reduced Infrastructure Costs

By partnering with an established manufacturing facility in Mexico, businesses can leverage existing infrastructure, such as production lines, warehouses, and distribution networks. This is instead of investing in building or updating existing facilities from scratch. This can significantly reduce the initial capital expenditure associated with setting up an existing facility in the U.S. or Canada.

Lower Labor Costs with Skilled Workforce

Mexico offers a highly skilled and experienced labor pool, especially in automotive, electronics, and aerospace. Mexico's labor costs are often lower than the U.S. or Canada. This allows companies to access skilled labor without higher domestic hiring costs. This cost advantage extends beyond wages to include benefits, training, and labor-related overheads.

Access to Established Supply Chains

A nearshore manufacturing partner in Mexico has an established supply chain network. This reduces businesses' need to invest in supply chain infrastructure. These partners can provide quicker access to raw materials and components, lowering procurement costs and improving speed to market. This benefit helps reduce working capital tied up in inventory and minimizes delays.

Shared Equipment and Technology Investments

Rather than purchasing expensive manufacturing equipment or machinery, companies can leverage their Mexican manufacturing partners' advanced technology and equipment. These shared resources eliminate upfront investments in upgraded equipment and reduce ongoing maintenance and upgrade costs.

Regulatory and Tax Incentives

Mexico offers several tax incentives for foreign manufacturers, such as the IMMEX (Maquiladora) program, which allows temporary imports of goods and materials with tariff exemptions, provided the finished goods are exported. This can reduce customs duties, taxes, and tariffs, lowering production costs. Additionally, navigating local regulations can be more straightforward with a local partner who knows compliance requirements. This reduces the risk of costly fines or delays.

Government Incentives for Reshoring in Mexico

By strategically aligning with the global trend of reshoring, leveraging Mexico's proximity to the U.S., benefiting from favorable trade agreements like the USMCA, and tapping into cost advantages, companies can position themselves for sustained success. This white paper explores the nuanced details of government incentives in Mexico. It will provide a comprehensive guide for businesses navigating reshoring opportunities. Fill out the form to receive the white paper today.

Lower Transportation and Logistics Costs

Nearshoring to Mexico can significantly reduce transportation and logistics costs compared to overseas options. The proximity to North American markets means shorter transit times and reduced shipping costs, which offset reshoring costs. The reduction in lead times can also enhance supply chain resilience and flexibility, further minimizing inventory management financial risks.

Flexible Contract Manufacturing Arrangements

By engaging with a nearshore partner, businesses can often benefit from flexible contract manufacturing arrangements. This allows them to scale production up or down based on demand without making large, fixed investments in their own facilities. This flexibility can help companies manage cash flow more effectively and reduce financial risks associated with fluctuating market conditions.

Faster Time to Market

A nearshore partner in Mexico can offer faster time to market due to geographical proximity, shorter lead times, and established processes. This speed advantage allows companies to capitalize on market opportunities faster and reduces the time required to generate revenue, offseting initial investments.

Risk Mitigation Through Diversification

Partnering with a Mexican manufacturer allows businesses to diversify their production base, reducing the risks associated with concentrating all production in one country. This risk mitigation can protect against disruptions and lower the financial impact of unexpected events, such as supply chain interruptions or geopolitical issues.

Conclusion: Cost-Benefit Analysis of Reshoring Is Worthwhile

Reshoring manufacturing cost-benefit analysis is a multifaceted process that requires careful consideration of both immediate expenses and long-term gains. While reshoring presents significant initial costs, the benefits, including improved quality control, reduced lead times, and increased customer trust, make it a worthwhile investment. Additionally, partnering with a nearshore manufacturing partner in Mexico, such as NovaLink, offers strategic middle ground, providing cost-effectiveness and operational efficiency. By weighing these factors carefully, companies can make informed decisions that align with their long-term business goals.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about reshoring to Mexico with our curated collection of related blog posts.

- Can Moving Manufacturing to Mexico Really Be Turnkey? Here’s What You Need to Know

- What Type of Company Should Not Move to Mexico?

- Stop Waiting: Mexico Product Manufacturing Is Ready When You Are

- 3 Hidden Costs You’re Avoiding by Manufacturing in Mexico (And Why It Matters)

- What Your CFO Needs to See Before Approving a Move: Why Moving Manufacturing from China to Mexico Makes Dollars and Sense

FAQs on Cost-Benefit Analysis of Reshoring Manufacturing

1. What is reshoring manufacturing?

Reshoring manufacturing involves bringing production processes back to the company's home country after having been previously outsourced to foreign locations.

2. How does reshoring affect supply chain management?

Reshoring can simplify supply chain management by reducing the distance between production and end markets, thus lowering transportation costs and minimizing the risk of disruptions.

3. What are the main financial challenges of reshoring?

The main financial challenges of reshoring include the initial capital investment, higher domestic labor costs, and potential supply chain adjustments that may increase costs.

4. Why consider nearshoring to Mexico instead of reshoring domestically?

Nearshoring to Mexico offers a balance of lower labor costs and proximity to the U.S., which can reduce transportation costs and lead times while still benefiting from a skilled workforce.

5. How does partnering with NovaLink influence the cost-benefit analysis of reshoring?

Partnering with NovaLink can optimize the cost-benefit analysis of reshoring by providing cost-effective manufacturing solutions, efficient supply chain management, and access to skilled labor, all while maintaining proximity to the U.S. market.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.