Last Updated on November 12, 2024

When considering manufacturing in Mexico, two primary models often come up: the Maquiladora vs. Shelter program. Both offer distinct benefits, but choosing the right one depends on your business's specific needs. This article will discuss the differences between the two models and help you determine which is most suitable for your company. Plus, we’ll explore how partnering with a nearshore manufacturer like NovaLink can streamline your entry into the Mexican market.

What is a Maquiladora?

A Maquiladora is a Mexican manufacturing operation that allows foreign companies to import materials and equipment duty-free. Finished goods are typically exported back to their country of origin. This program was designed to attract foreign investment and create jobs in Mexico.

Companies operating under the Maquiladora model benefit from lower labor costs, tax advantages, and proximity to the U.S. market. However, the Maquiladora requires a substantial commitment to setting up a legal entity in Mexico. This includes managing local regulations compliance, and handling all aspects of the business, from payroll to human resources.

How do Maquiladoras and IMMEX differ?

There is a key difference between Maquiladoras and IMMEX in Mexican manufacturing. IMMEX is an acronym for "Industria Manufacturera, Maquiladora y de Servicios de Exportación" (Manufacturing, Maquiladora, and Export Services Industry). Basically, it's a government program that encourages foreign companies to establish Maquiladoras in Mexico. In addition to offering duty exemptions, the program streamlines customs procedures. As an analogy, think of IMMEX as a special club for Maquiladoras. IMMEX offers its members (Maquiladoras) benefits.

The terms have become interchangeable over time. Maquiladoras are often used to refer to IMMEX as a whole. Maquiladoras are factories, and IMMEX is the program they operate under.

Understanding the Shelter Program

In contrast, the Shelter Program is a turnkey solution for companies that want to start manufacturing in Mexico without establishing a full legal presence. Under this program, a third-party provider (the "Shelter") assumes responsibility for all legal and administrative burdens. This includes handling permits, human resources, payroll, and compliance with Mexican laws.

The Shelter Program minimizes risk and speeds up market time. Companies using this model focus on their core competencies, such as production and quality control, while the shelter provider handles everything else.

Maquiladora vs. Shelter Program: Key Differences

Choosing between a Maquiladora vs. Shelter Programs hinge on several critical differences:

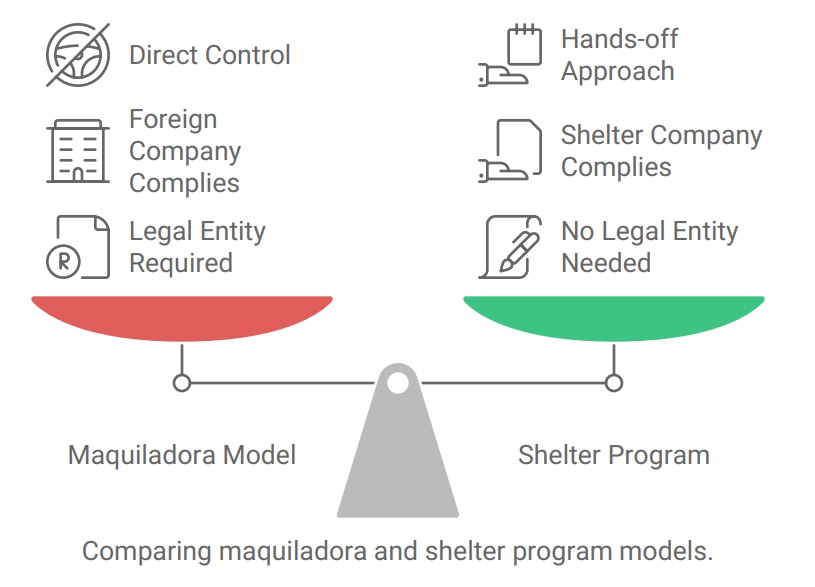

- Legal Entity Requirement: Maquiladora requires the foreign company to establish a Mexican legal entity, while a shelter program does not.

- Compliance Responsibility: In a Maquiladora, the foreign company is responsible for all compliance. In a shelter program, the shelter company assumes these responsibilities.

- Control and Flexibility: Maquiladora provides more direct control over operations, while a shelter program offers a more hands-off approach with less control over day-to-day activities.

- Risk and Liability: The shelter program reduces risk and liability for the foreign company, whereas the Maquiladora model involves higher risk due to direct legal and fiscal responsibilities.

- Cost and Investment: Maquiladora requires higher initial investment and ongoing costs related to compliance and administration, while the shelter program offers lower initial costs and reduces administrative expenses.

Which Option is Right for Your Business?

So, which model is right for your business: Maquiladora or Shelter Program? The answer depends on your company's goals, resources, and risk tolerance.

- Choose the Maquiladora if you want full control over operations and are prepared for a larger financial and time investment. This model is ideal for companies planning long-term, large-scale production in Mexico.

- Opt for the Shelter Program if you want a quick, low-risk entry into the Mexican market. This is suitable for companies that wish to test the waters or start small and scale up over time.

Why Partner with a Nearshore Manufacturer like NovaLink?

Regardless of the model you choose, working with a nearshore manufacturing partner like NovaLink can smooth your transition. As a partner in your manufacturing operation, NovaLink offers expertise in setting up a Maquiladora while still allowing the client the freedom to control their manufacturing. Their experience and infrastructure can help you get your Maquiladora operation up and running quickly and efficiently. By partnering with NovaLink, you gain access to a reliable supply chain, reduce costs, and accelerate your time to market.

Conclusion

Understanding the differences between a Maquiladora vs. Shelter Programs are crucial for any company looking to manufacture in Mexico. Each model offers distinct advantages, and the right choice depends on your company's needs, goals, and resources. For a hassle-free entry into the Mexican market, consider partnering with a nearshore manufacturer like NovaLink to streamline the process and ensure smooth operation from day one.

FAQs on Maquiladora vs. Shelter Program

1. What is the primary difference between the Maquiladora and Shelter Program?

The primary difference lies in the level of control and risk. The Maquiladora provides full control but requires handling all legal and administrative tasks, while the Shelter Program minimizes risk by outsourcing these responsibilities to a third-party provider.

2. How quickly can I start manufacturing in Mexico under the Shelter Program?

The Shelter Program offers a faster time to market since it bypasses the need to establish a legal entity in Mexico. Companies can typically begin operations within weeks.

3. What are the financial implications of choosing the Maquiladora model?

The Maquiladora model requires a higher initial investment due to the need to establish and maintain a legal presence in Mexico. However, it offers more control over operations and can be more cost-effective for long-term, large-scale production.

4. Can I switch from the Shelter Program to the Maquiladora model later?

Yes, many companies start with the Shelter Program to minimize risk and gain market entry. Once they are confident in their operations, they can transition to a Maquiladora model for greater control.

5. How does partnering with NovaLink benefit my manufacturing operation in Mexico?

NovaLink provides expertise, infrastructure, and a reliable supply chain for both Maquiladora and Shelter Program setups, helping companies start quickly and operate efficiently in the Mexican market.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into Maquiladoras in Mexico with our curated collection of related blog posts.

- What Type of Company Should Not Move to Mexico?

- Mexico’s Manufacturing Workforce in 2025: A Game-Changer for Global Industry

- How to Find the Best Maquiladora for Your Manufacturing Needs

- Strategic Measures to Fortify Mexico’s Textile Industry Under President Claudia Sheinbaum

- Labor vs. Land: What Costs More in Mexican Manufacturing?

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.