Last Updated on December 12, 2024

When considering manufacturing in Mexico, efficiency isn’t just an aspiration—it’s a necessity. One metric reigns supreme in this pursuit: OTIF, or On-Time In-Full. This cornerstone of operational excellence ensures that supply chains hum along like a well-oiled machine, delivering precisely what’s needed, exactly when it’s promised. But why does OTIF matter so much, and how does it factor into Mexico's manufacturing edge? Let’s explore.

What Is OTIF and Why Should You Care?

At its core, OTIF measures a supplier’s or manufacturer's ability to fulfill orders on time and in full. Imagine you expect 1,000 components for delivery on Friday. If they show up incomplete or late, it’s not just inconvenient—it’s a disruption. OTIF tracks two critical dimensions:

- On-Time: Was the delivery made when promised?

- In-Full: Did it include the exact quantity ordered?

OTIF isn’t just a box-ticking exercise. It’s the heartbeat of any reliable supply chain. When OTIF scores falter, so do relationships, production schedules, and, ultimately, bottom lines.

The Challenges of Hitting OTIF Goals

Achieving stellar OTIF performance is easier said than done. From complex data management to unforeseen supply chain hiccups, manufacturers face significant hurdles. Let’s unpack some:

- Data Management Nightmares: Ever tried gathering real-time data from multiple suppliers without robust tools? It’s like herding cats. Missing or outdated information can wreak havoc on OTIF scores.

- Bottlenecks: Whether it’s delayed raw materials or production snags, every hiccup compounds downstream delays.

- Customer Standards: Some clients penalize late deliveries, while others impose fines for early arrivals. Striking the perfect balance requires meticulous planning.

Why Real-Time Supply Chain Visibility Is a Game-Changer

Here’s the thing: you can’t fix what you can’t see. That’s where real-time visibility tools come in. With advanced tracking systems, manufacturers gain an up-to-the-minute view of their supply chain.

- Know Where Everything Is: From raw materials to finished goods, visibility tools provide clarity at every step.

- Proactive Problem-Solving: Spot a delay brewing? Redirect resources before it snowballs into a missed delivery.

- Minimized Penalties: Avoid fines by ensuring products arrive neither early nor late but right on schedule.

Mexico’s manufacturing sector benefits immensely from these tools, enabling it to maintain its reputation for reliability in a fiercely competitive global market.

Calculating OTIF: A Simple Formula, Complex Impact

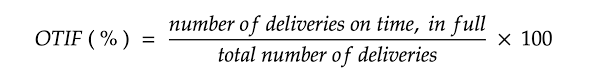

While the concept seems straightforward, calculating OTIF requires precision. It’s typically expressed as:

For example, if 90 out of 100 deliveries meet both criteria, your OTIF score is 90%. Sounds simple, right? But the devil’s in the details. A single late or partial delivery can ripple through production schedules, proving how high the stakes are.

The Difference Between OTIF and Availability

Understanding the difference between OTIF and Availability is essential for optimizing supply chain performance. While both metrics aim to improve customer satisfaction, they address distinct areas. OTIF focuses on the supplier's ability to deliver orders on the agreed timeline and in the correct quantities, directly reflecting the reliability and efficiency of order fulfillment processes.

In contrast, Availability measures whether products are in stock and ready to meet customer demand at any given time, emphasizing inventory management and demand planning. For example, a high OTIF score means customers receive their orders as promised, but low availability could still lead to lost sales if items aren’t in stock when needed. By balancing OTIF and Availability, businesses can ensure seamless operations, minimize delays, and build stronger customer trust.

Key Differences

| Aspect | OTIF | Availability |

|---|---|---|

| Primary Goal | Delivery performance | Stock readiness |

| Focus on Timeline | Critical (on-time delivery) | Not necessarily time-bound |

| Customer Experience | Ensures orders are fulfilled as promised | Ensures products are always ready to sell |

| Dependency | Relies on logistics and order fulfillment | Relies on inventory management and demand planning |

In summary, OTIF focuses on the accuracy and punctuality of delivering orders, while Availability is about ensuring sufficient stock to meet demand. Both are crucial for effective supply chain management but address different challenges.

How Mexico’s Manufacturing Edge Depends on OTIF

Manufacturers in Mexico have carved out a niche as global supply chain powerhouses, thanks in part to their mastery of OTIF principles. Here’s why this matters:

- Geographic Advantage: Proximity to major markets like the U.S. shortens delivery times, but OTIF ensures those timelines are consistently met.

- World-Class Infrastructure: Modern ports, highways, and rail systems support on-time deliveries.

- Skilled Workforce: Mexico's workforce understands the importance of precision and reliability, bolstering OTIF scores across industries.

By focusing on OTIF, Mexico’s manufacturers solidify their reputation as dependable partners, attracting businesses looking for a smooth transition to nearshoring.

Building Better Partnerships with OTIF

When manufacturers prioritize OTIF, they build trust. Customers know they can count on them, and that predictability fosters long-term relationships. But it’s not just about keeping promises—it’s about exceeding expectations.

The Bottom Line

Mexico’s manufacturing edge isn’t just about location or cost savings. It’s about reliability, and OTIF is the unsung hero making that possible. By mastering OTIF metrics, manufacturers in Mexico ensure they’re not just meeting expectations—they’re setting the standard.

FAQs on Mexico's Manufacturing Edge and OTIF

What does OTIF stand for in manufacturing?

OTIF stands for On-Time In-Full, a metric measuring whether deliveries arrive on schedule and in the exact quantities ordered.

How does OTIF impact supply chains?

A strong OTIF score reduces disruptions, builds customer trust, and minimizes penalties for late or incorrect shipments.

Why is OTIF particularly relevant in Mexico?

Mexico’s geographic proximity to major markets and its efficient infrastructure make OTIF crucial for maintaining competitive lead times and supply chain reliability.

What tools help improve OTIF scores?

Real-time supply chain visibility tools, like advanced analytics platforms, help track shipments, identify bottlenecks, and ensure on-time, accurate deliveries.

How can businesses transitioning to Mexico prioritize OTIF?

Partner with local experts, invest in real-time tracking systems, and focus on robust communication with suppliers to ensure seamless operations.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about Mexico Supply Chain with our curated collection of related blog posts.

- How Mexico Is Strengthening Supply Chains for Long-Term Stability

- How to Find Your Ideal Mexico Manufacturing City

- Is Your Supply Chain Ready for a Mexico Move?

- Mexico’s Customs Clearance: Why It’s Faster—and Smarter—for Manufacturers

- How to Streamline Supply Chains in Mexico Without Losing Your Mind (or Your Margin)

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.