Last Updated on September 5, 2023

Wire management products play an important role in the smooth operation of various industries in today's interconnected world. For the organization, protection, and maintenance of electrical and communication systems, wire management solutions are indispensable in a wide variety of industries, including telecommunications, automotive, energy, and construction. The process of ensuring global standards for wire management products can, however, be a complex one, resulting in inefficiencies, substandard quality, and increased costs. Our article will discuss the importance of harmonizing global standards for wire management products and how partnering with a nearshore manufacturing partner in Mexico can help achieve this goal while driving innovation and reducing costs.

Understanding the Need for Global Standards in Wire Management Products

The Importance of Global Standards

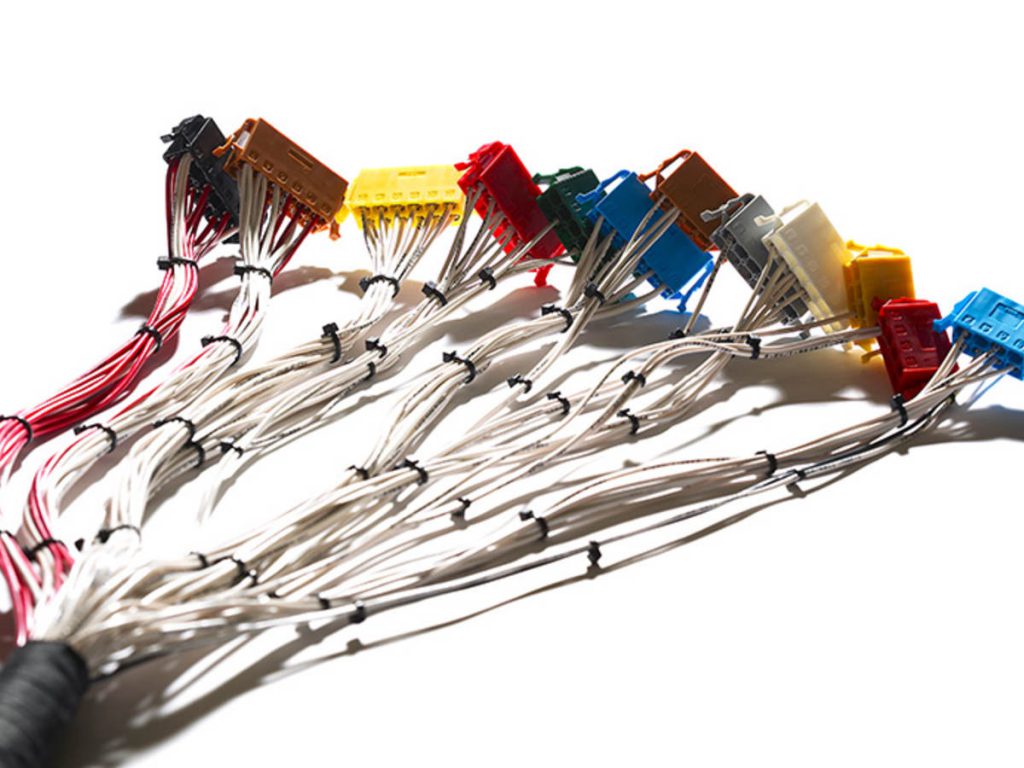

Wire management products, such as wire harnesses, cable ties, conduits, and connectors, need to meet specific quality and safety requirements to function effectively. Global standards ensure uniformity in design, manufacturing, and performance, enabling seamless integration of wire management solutions across borders. This fosters interoperability, simplifies installation processes, and enhances system reliability.

Challenges of Diverse Standards

Diverse standards across different regions pose significant challenges for wire management manufacturers and end-users. Incompatibility issues, non-compliance with regulations, and the need for multiple product variations result in increased complexity and costs. Harmonizing global standards addresses these challenges by establishing a unified framework that facilitates market access, reduces redundancy, and promotes cost-effective manufacturing processes.

Reducing the number of separate standards and testing requirements provides a substantial opportunity for OEMs to promote products that are high value, have consistent quality, and have a safe and efficient application, while also ensuring product performance and high quality based on the successful completion of test standards.

How The Global Harmonization Of Wire Harness Standards Will Impact Heavy Equipment Specification Decision Making

The Benefits of Harmonizing Global Standards

Enhanced Innovation

Harmonizing global standards for wire management products promotes innovation by streamlining product development cycles. Manufacturers can focus on designing cutting-edge solutions rather than adapting to regional requirements. This encourages the introduction of various materials, technologies, and features, ultimately driving industry progress.

Cost Reduction

Global standardization optimizes manufacturing processes, supply chains, and economies of scale. With uniform design specifications and regulatory compliance, wire management manufacturers can consolidate production, reduce redundancy, and eliminate excessive customization. This leads to cost savings, which can be passed on to customers, making wire management products more affordable and accessible.

Leveraging Nearshore Manufacturing in Mexico for Global Standards Compliance for Wire Management Products

Proximity and Connectivity

Mexico's strategic location, bordering the United States, makes it an ideal nearshore manufacturing partner for companies seeking to harmonize global standards for wire management products. Close proximity ensures reduced lead times, facilitates collaboration, and allows for quick response times to market demands and evolving standards.

Skilled Workforce and Expertise

Mexico has a skilled workforce with wire management expertise. The country's commitment to education and vocational training programs ensures a talent pool capable of meeting global standards. Manufacturers in Mexico can provide high-quality products while adhering to global regulations and industry best practices. Additionally, manufacturing in Mexico can help companies comply with global standards, such as ISO 9001 and AS9100, which are important for wire management products.

Cost-Effective Manufacturing

Collaborating with a nearshore manufacturing partner in Mexico offers cost advantages without compromising quality. The country provides competitive labor rates, favorable trade agreements, and a robust infrastructure, enabling efficient production and cost optimization. By leveraging these advantages, companies can align their wire management products with global standards in a cost-effective manner.

Conclusion: Embracing Global Standards

Harmonizing global standards for wire management products is essential to unlock innovation, reduce costs, and enhance overall product quality. By adopting a unified framework, wire management manufacturers can streamline production processes, drive innovation, and ensure compliance with global regulations. Partnering with a nearshore manufacturing partner in Mexico brings added advantages of proximity, skilled workforce, and cost-effective manufacturing. Embracing these opportunities will not only benefit manufacturers but also lead to improved wire management solutions that meet global standards, fueling growth across industries.

FAQs:

Q1: Why are global standards important for wire management products?

A1: Global standards ensure uniformity, interoperability, and reliability, simplifying installation and enhancing overall system performance.

Q2: How does harmonizing global standards drive innovation?

A2: Harmonization frees manufacturers from adapting to multiple regional requirements, enabling them to focus on designing cutting-edge wire management solutions.

Q3: What cost advantages does nearshore manufacturing in Mexico offer?

A3: Mexico provides competitive labor rates, favorable trade agreements, and a robust infrastructure, enabling cost-effective wire management product manufacturing.

Q4: Can partnering with a nearshore manufacturing partner affect lead times? A4: Yes, partnering with a nearshore manufacturing partner, such as Mexico, reduces lead times due to close proximity and enhanced connectivity.

Q5: How can nearshore manufacturing in Mexico ensure compliance with global standards?

A5: Mexico boasts a skilled workforce and expertise in wire management manufacturing, ensuring adherence to global regulations and industry best practices.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.