Last Updated on March 26, 2025

Knowing the principles of strategic sourcing in Mexico is a key element of success for companies that want to implement strategies to negotiate and better interact with Mexican suppliers. This article will explain the fundamentals of strategic sourcing in Mexico and how to apply them to improve the purchasing and supply process.

Defining Strategic Sourcing in Mexico

Strategic sourcing is the logical and sequential process that analyzes the internal demands of a company. That is, it provides managerial staff with an overview of the materials, goods, and services that it needs to operate the company. The process aims to determine an organization’s position in the market with its suppliers and devise strategies that improve negotiation processes, decrease risk levels, and increase opportunities for savings and cost reduction. Success in sourcing in Mexico depends upon how well a company analyzes and acts upon its unique situation.

Strategic sourcing can be clearly defined as a systematic, organized, and collaborative way of identifying competitive suppliers to achieve long-term agreements with them to ensure the supply of the goods and services that a company needs over time.

Benefits of strategic sourcing in Mexico

Working capital optimization

When a strategic supply model is applied to a company, it can reduce the total cost of purchase (TCO) considerably, expand payment terms, and reduce logistics costs associated with the sourcing process. What is the result? Greater cash liquidity and working capital are available for other productive activities.

Efficiency in the Mexican sourcing process

It should be noted that although the strategic sourcing model and the purchasing process are two different mechanisms, both are very directly related to each other.

The purchasing process is when sourcing in Mexico involves all the stages that a company must carry out internally to issue a purchase order to a supplier, receive the requested merchandise, and pay for it in due time. Strategic sourcing, however, extends beyond purchases and focuses on taking advantage of local Mexican and global market conditions to improve negotiation processes and customer-supplier relationships.

In this sense, when a company implements a strategic supply model due to the substantial amounts of raw materials and supplies that it needs to tender and buy annually, it automatically needs to lay the foundations of how the purchasing process is going to be used from a strategic perspective. It must be effective in ensuring that, in practice, all commercial transactions are carried out in an organized manner, on schedule, and under meticulous control of all necessary paperwork and approval systems that the company has in place.

Alignment and professionalization of Mexican procurement teams:

Together with the aforementioned ideas, the strategic supply model gives the Mexican purchasing process an orderly methodology of how to transpire and makes supply the protagonist in the fulfillment of the corporate goals and objectives of a company.

The purchasing teams that have worked with this methodology experience a greater commitment to the results and begin to professionalize their functions. They also transform the Mexico sourcing process into a strategic function that generates important added value for a company.

Principles of Strategic Sourcing in Mexico That You Should Know

View supplier base rationalization in Mexico as a result, not a goal

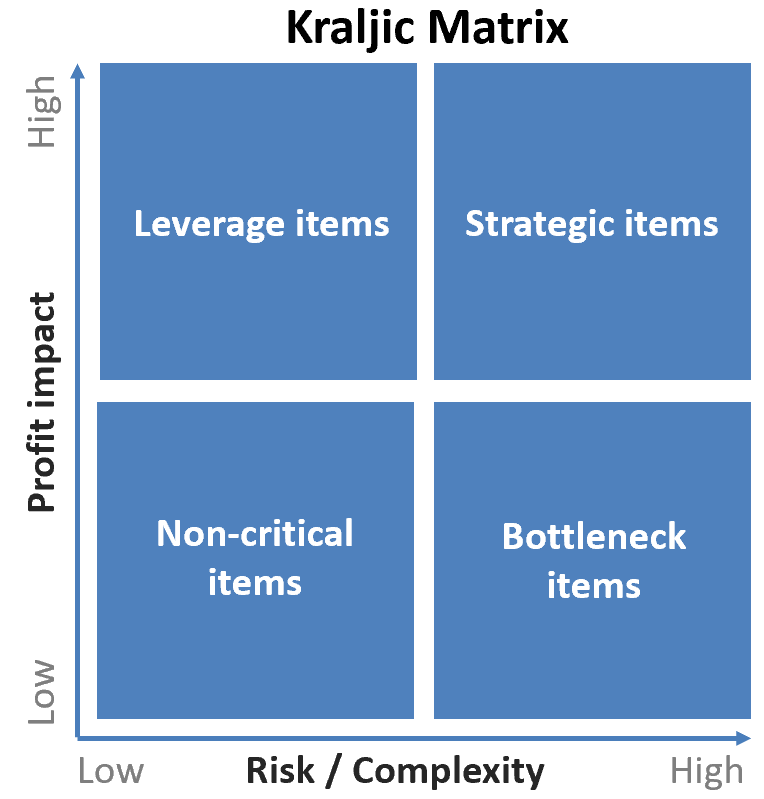

In the third stage of the strategic sourcing methodology, called "supplier portfolio,” a list of suppliers must be made for each product category identified using the Kraljic Matrix. For this type of classification to be even more strategic, it is important to rationalize a company’s supplier base. This is achieved by considering whether it is necessary to increase or decrease its size according to the priority levels that each product yields.

For example, if a company manufactures automobiles in Mexico, it is convenient to have more suppliers for those inputs that are essential in the production process. This may include things such as tires, mechanical parts to assemble the engine, and upholstery fabric (to name a few). In order to optimize a company’s supplier portfolio, it is recommended that those sourcing in Mexico:

- Analyze the cost/benefit of reducing or expanding it.

- Assess the role that each current supplier plays.

- Never lose sight of the Total Acquisition Cost (TAC), which represents the added expenses that are necessary until the merchandise is in the warehouse and can be included in the company’s Mexican supply chain.

Use of cross-functional teams

Developing a sourcing strategy in Mexico should be viewed as an organizational skill and not just the exclusive purview of the purchasing or procurement department. At the moment, when companies must gather their work teams to develop their own strategic supply models, they should not limit themselves to only including experts in the area. They will be well served to try also involving experts in finance, accounts payable, administration, managers from the warehouse, the operational manager, the production manager, etc.

The more relevant staff that the company gets involved with, the more diversity of opinion there will be. It follows that this will generate more creative input. Cross-functional work makes Mexico sourcing strategy design an organizational activity.

Although unilaterally developed plans can effectively deal with competitive situations that usually arise in the purchasing area, without the support of other functions, such as Production and Engineering, these opportunities for cooperation may not be realized.

Conduct rigorous global investigations

Many Mexico sourcing strategies start with a current supplier portfolio. However, the effective development of a successful procurement process can potentially benefit from a wider global vision.

Sourcing staff must be sure that it has taken the time to investigate whether there are, in addition to Mexico and the rest of North America, suppliers that can meet the company’s needs on the other side of the ocean. For example, there may be companies in Asia or India that can supply the basic inputs necessary for production at a more accessible price, with acceptable payment terms and credit terms. It is very important to remember, however, that products from sources outside of North America will most likely be subject to tariffs and duties that do not apply to similarly sourced items in the United States – Mexico – Canada free trade zone (USMCA).

The truth is that global research can sometimes enable companies that are manufacturing in Mexico to find a previously unknown advantageous supplier. To assess whether a company is ready to put this principle into practice, sourcing staff must ask:

- Is my supply exclusively from a local source?

- Do I meet the conditions and requirements to import?

- How does import affect the industrial sector?

- Does it improve my Total Cost of Acquisition?

- Do I already have my Sourcing Group defined?

In this sense, among the principles of strategic sourcing in Mexico, there can be a benefit in evaluating what is currently happening in global markets in terms of spending, supply, and opportunities. Taking these factors into account can help to make the sourcing process much more strategic.

Quantify the Benefits of Sourcing in Mexico

To have an exemplary strategic supply process, it is not only necessary to define correct strategies, but companies must also do the work to define the appropriate KPIs that are aligned with management’s set goals. It is impossible to know if the model used to source for manufacturing in Mexico has had the desired impact if it is not attached to performance with metrics. Here is a list of possible KPIs to measure the performance of your strategic sourcing:

- Total Lead Time.

- Purchasing Lead Time.

- Supplier Lead Time.

- Logistics Lead Time.

- Promise Performance.

- Budget.

- Service level.

- Payment conditions.

- price comparisons

In short, strategic supply or strategic sourcing is not only a trend in world-class companies. It currently constitutes a management methodology that every organization should follow when creating strategic relationships with suppliers. Well-chosen suppliers and well-executed sourcing in Mexico can help achieve organizational objectives and evaluate what is currently happening in the markets regarding spending, supply, and opportunities to improve a competitiveness and value chain

FAQs on Principles of Strategic Sourcing in Mexico

Q1: What is strategic sourcing, and how does it relate to Mexico?

A1: Strategic sourcing involves a comprehensive approach to procurement that focuses on achieving cost savings, quality improvement, and supply chain optimization. In Mexico, strategic sourcing leverages the country's manufacturing capabilities, skilled labor force, and favorable trade agreements to maximize value for businesses.

Q2: What are the key benefits of implementing strategic sourcing principles in Mexico?

A2: Implementing strategic sourcing in Mexico offers several advantages, including reduced procurement costs, access to specialized expertise, shortened lead times, enhanced supply chain resilience, and improved collaboration with local suppliers.

Q3: How does strategic sourcing in Mexico contribute to cost savings?

A3: Strategic sourcing in Mexico allows businesses to tap into the country's competitive labor and operational costs. By optimizing supplier relationships and streamlining processes, companies can achieve significant cost reductions without compromising quality.

Q4: What role do trade agreements play in strategic sourcing in Mexico?

A4: Mexico's participation in trade agreements like USMCA (United States-Mexico-Canada Agreement) provides tariff-free access to key markets. This trade advantage reduces costs and enhances market reach for businesses engaged in strategic sourcing in Mexico.

Q5: How can companies ensure ethical and sustainable sourcing practices in Mexico?

A5: Companies can prioritize ethical and sustainable practices in strategic sourcing by conducting thorough supplier audits, promoting fair labor practices, and adhering to environmental regulations. Collaborating with local suppliers who share these values ensures a responsible sourcing approach in Mexico.

Q6: What risks are associated with sourcing in Mexico and how can they be managed?

A6: When considering Mexico as a sourcing destination, it's crucial to be aware of the potential risks involved. These encompass a range of issues, such as:

- Political Instability: Changes in government policies or political unrest can impact trade and business operations.

- Labor Disputes: Strikes or conflicts within the workforce may disrupt manufacturing and supply chains.

- Natural Disasters: Events like earthquakes or hurricanes can damage infrastructure and halt production.

- Cybersecurity Threats: With increasing reliance on digital systems, the risk of data breaches or cyber-attacks is ever-present.

Effective Risk Management Strategies

To navigate these challenges, companies can employ several strategies:

- Diversify Suppliers: Relying on multiple suppliers can reduce dependency on a single source and safeguard against disruptions.

- Develop Contingency Plans: Having backup plans ensures quick responses to unforeseen events, minimizing downtime.

- Stay Informed: Regularly monitoring market trends and geopolitical developments can help anticipate and respond to potential risks proactively.

By implementing these strategies, businesses can effectively manage the uncertainties of sourcing from Mexico, ensuring a smoother and more resilient supply chain.

Q7: What is The State of Transportation and Infrastructure in Mexico?

A7: Mexico boasts a robust transportation network that is fundamental to effective logistics and supply chain management. With an extensive array of modern highways, railways, and well-equipped airports, the movement of goods across the nation is facilitated with relative ease.

Key Considerations:

- Geographic Challenges: Despite the well-developed infrastructure, attention must be given to the country's diverse topography, which can impact transportation routes and times.

- Customs and Border Issues: Efficient logistics management necessitates a thorough understanding of customs clearance procedures and potential delays at border crossings. These factors are critical when planning supply chains that extend into or out of Mexico.

- Collaboration is Key: Engaging with knowledgeable logistics partners who are adept at navigating the complexities of cross-border trade can dramatically enhance operational efficiency.

In summary, while Mexico's transportation infrastructure supports smooth logistics operations, success in supply chain management requires careful planning and strategic partnerships to tackle geographic and regulatory challenges.

Q8: How Can Businesses Ensure Compliance with Mexican Trade Laws?

A8: Navigating the intricate legal landscape of Mexico requires diligence and strategic planning. Here’s how businesses can effectively ensure they remain compliant with Mexican trade laws:

- Implement Robust Internal Processes

- Develop clear and consistent internal processes. This involves creating a dedicated compliance team that is well-versed in the specific requirements of Mexican trade laws. Regular training sessions for employees about new regulations can keep everyone informed and proactive.

- Leverage Expertise

- Collaborating with legal experts familiar with Mexico’s trade regulations is invaluable. Partner with experienced legal counsel or consultants who specialize in this area. Their guidance can be crucial in interpreting complex legal requirements and offering practical solutions to compliance issues.

- Stay Informed about Legal Changes

- The regulatory environment in Mexico is dynamic, with frequent updates and changes. It's vital for businesses to keep abreast of these developments. Subscribing to industry newsletters, attending trade seminars, and being active participants in trade associations can provide timely insights into new regulations.

- Establish a Monitoring System

- Implementing a system for ongoing compliance monitoring can help identify potential issues before they escalate. Regular audits and assessments can pinpoint weaknesses in your compliance strategy, allowing for timely adjustments.

- Foster Collaborative Relationships

- Engage with local partners and industry groups who have a deeper understanding of the local market. Their insights can inform your compliance strategies and help adapt your operations seamlessly to regulatory changes.

By taking these steps, businesses can significantly reduce the risk of non-compliance, ensuring a smoother and more efficient process when sourcing from or operating in Mexico.

Q9: Why is Efficient Supply Chain Management is Crucial for Sourcing in Mexico?

A9: Efficient supply chain management is key when sourcing in Mexico for several reasons. Primarily, it ensures that goods, information, and finances move seamlessly from sourcing to delivery. By managing these flows effectively, businesses can enhance their operational efficiency and maintain a competitive edge.

One of the major benefits is cost-effectiveness. Properly coordinated supply chains help in reducing delays and avoiding unnecessary expenses. This means products reach their destinations on time and within budget, which is vital in a globalized economy where timing can significantly impact profitability.

Moreover, collaborating with suppliers, transportation providers, and other stakeholders is essential for overcoming geographical and logistical challenges. Such partnerships facilitate smoother operations, allowing companies to respond swiftly to market demands or unexpected disruptions.

Additionally, an efficient supply chain supports transparency and improved communication, ensuring that all parties involved are informed and aligned with the goals. This leads to faster decision-making processes and enhances the overall reliability of the supply network.

In short, mastering supply chain management in Mexico is not just beneficial but essential for any business looking to thrive in the region's dynamic market.

Q10: What Role Do Trade Agreements Like USMCA Play in Sourcing in Mexico?

Trade agreements like the United States-Mexico-Canada Agreement (USMCA) play a crucial role in enhancing Mexico's appeal as a sourcing hub. By removing trade barriers and reducing tariffs, these agreements facilitate smoother and more cost-effective supply chains between Mexico, the United States, and Canada.

Benefits of Trade Agreements in Sourcing:

- Reduced Costs: With decreased tariffs, businesses can import and export goods at lower costs.

- Market Access: Companies gain broader access to North American markets, allowing for easier expansion and increased competitiveness.

- Regulatory Streamlining: Harmonized regulations across member countries simplify compliance processes, saving time and resources.

Overall, agreements like the USMCA not only encourage businesses to source from Mexico but also enhance the efficiency and profitability of these ventures. As a result, Mexico stands out as a strategic choice for businesses aiming to tap into the North American market.

Q11: What is the Overview of the Mexican Economy Relevant to Sourcing?

Understanding the Mexican economy is essential if you're considering sourcing there. As the 11th largest economy globally, Mexico boasts a vibrant and diverse manufacturing sector. Industries like automotive, aerospace, electronics, medical devices, and textiles form the backbone of this industrial powerhouse.

For businesses contemplating sourcing from Mexico, it is important to delve deep into the specific industry you plan to engage with. Knowing the ins and outs of market dynamics is key. This insight will not only reveal opportunities but also help assess the competitive landscape effectively.

Furthermore, Mexico's geographical advantage cannot be overstated. Positioned as a gateway to the North American market, it provides easy access to the United States and Canada. This strategic location, combined with trade agreements like the United States-Mexico-Canada Agreement (USMCA), makes it an appealing choice for businesses aiming to broaden their reach.

Utilizing Mexico as a sourcing destination offers a blend of accessibility, industry diversity, and financial incentives, making it a robust option in the global marketplace.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into sourcing in Mexico with our curated collection of related blog posts.

- How Mexico Is Strengthening Supply Chains for Long-Term Stability

- Is Your Supply Chain Ready for a Mexico Move?

- How to Streamline Supply Chains in Mexico Without Losing Your Mind (or Your Margin)

- The Most Overlooked Advantage of Mexico’s Logistics Infrastructure

- Stop Wasting Time—These Are the Fastest Trade Routes in Mexico