Last Updated on December 11, 2024

The electronics industry in Mexico has become increasingly prominent in recent years. Businesses in the industry benefit from Mexico's strategic location, skilled workforce, and robust infrastructure. To achieve success in electronics manufacturing, however, it is imperative that the supply chain be streamlined effectively. We will explore the importance of streamlining the supply chain and discuss key strategies that can contribute to successful electronics manufacturing in Mexico in this article.

Streamlining Supply Chain: The Key to Successful Electronics Manufacturing in Mexico #ems #mexico #manufacturing #novalink Share on XUnderstanding the Importance of Supply Chain Streamlining

Enhancing Efficiency and Cost Savings

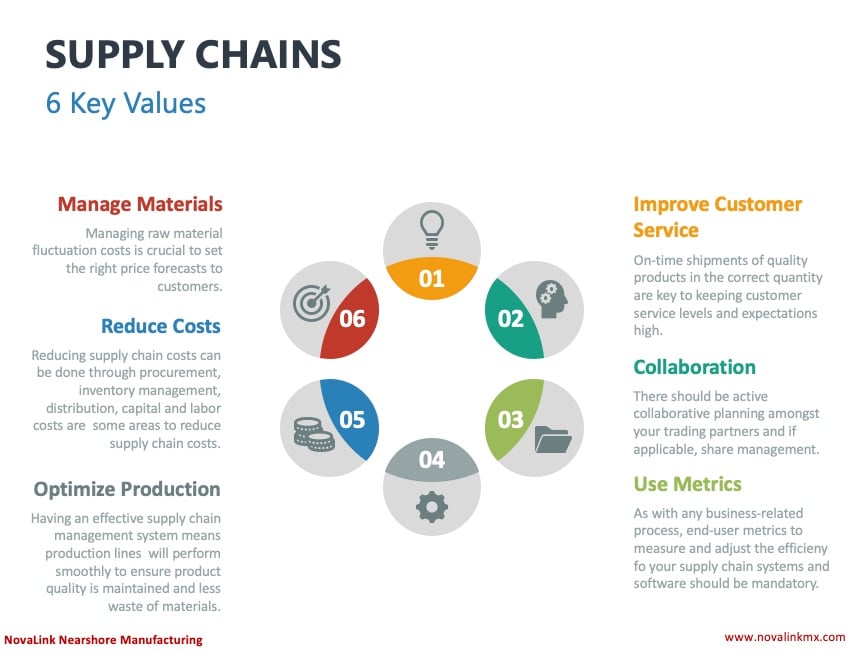

Supply chain management plays a crucial role in electronics manufacturing success. As a result of streamlining the supply chain, companies are able to reduce lead times, eliminate bottlenecks, and optimize their operations. This results in improved efficiency, reduced costs, and increased market competitiveness.

Minimizing Risks and Ensuring Quality

In addition, a well-organized supply chain helps mitigate risks associated with disruptions, such as delays or shortages of components. It enables effective inventory management, ensuring the right components are available at the right time. Moreover, streamlining the supply chain allows for better quality control, reducing defects or errors in the manufacturing process.

As part of the manufacturing operations of electronics systems and PCB production, planning for supply chain success is imperative. Without a cohesive plan, shortages of components or materials could cause a line down situation. Conversely, a burden of oversupply and inventory can induce large carrying costs that can be prohibitive on profits. Management of information, originating from the customer, all the way through to final shipment of inventory is the key to winning logistics challenges.

MicroFab: Supply Chain Management for Electronics Manufacturing

Key Strategies for Streamlining the Supply Chain

Supplier Relationship Management

In the field of electronics manufacturing, strong partnerships with suppliers are vital to optimizing the supply chain. Maintaining a consistent and reliable flow of materials depends on close collaboration with trusted suppliers. In order to achieve this, it is necessary to cultivate effective communication channels, to provide timely feedback on product specifications and quality requirements, and to conduct periodic assessment of supplier performance. For instance, in the context of printed circuit board assembly, establishing strong relationships with reliable PCB manufacturers allows electronics companies to secure a steady supply of high-quality boards, minimizing production delays and ensuring timely delivery of finished products.

Just-in-Time (JIT) Inventory Management

Electronic manufacturing benefits greatly from just-in-time (JIT) inventory management. It is based on the concept of receiving components and materials precisely when they are required in order to minimize inventory levels. JIT allows manufacturers to significantly reduce carrying costs, minimize waste, and improve cash flow. For JIT to be successfully implemented in electronics manufacturing, accurate demand forecasting is crucial. Market trends, customer demands, and production requirements are carefully analyzed by manufacturers so that the exact quantity and timing of component orders can be determined, avoiding excess inventory and stockouts. Mexico's proximity to the United States makes it an ideal location for electronics manufacturing companies using the just-in-time inventory model.

Implementing Advanced Technology Solutions

Leveraging advanced technology can significantly streamline electronics manufacturing supply chains. Automation, data analytics, and cloud-based systems enable real-time inventory tracking, efficient demand planning, and seamless collaboration between stakeholders. Adopting Industry 4.0 technologies like the Internet of Things (IoT) and artificial intelligence (AI) can revolutionize the manufacturing process and improve overall supply chain visibility.

Continuous Process Improvement

To ensure ongoing supply chain optimization, it is essential to prioritize continuous improvement. This can be achieved through the implementation of Lean Six Sigma methodologies, conducting regular performance evaluations, and fostering a culture of innovation and learning. By identifying and eliminating inefficiencies, manufacturers can enhance their supply chain operations.

Streamlining Supply Chain in the Mexican Electronics Manufacturing Industry

Leveraging Mexico's Strategic Location

The proximity of Mexico to the United States is an important advantage for electronics manufacturers. Due to the short distance, transportation is more rapid, lead times are reduced, and shipping costs are lower. By strategically locating manufacturing facilities and distribution centers, companies can streamline the supply chain and cater to North American market demands efficiently.

Developing a Skilled Workforce

Mexico is renowned for its substantial pool of skilled workers within the electronics manufacturing industry. The country has established itself as a prominent destination for electronics manufacturing due to its highly competent workforce. To capitalize on this advantage, companies operating in Mexico often prioritize investing in training programs and talent development initiatives. By doing so, they ensure that the workforce is equipped with the essential skills and knowledge required to handle advanced manufacturing processes.

Companies in Mexico understand the importance of staying up-to-date with the latest technological advancements in the electronics industry. As a result, training initiatives often incorporate education on emerging technologies, such as Internet of Things (IoT), artificial intelligence (AI), and Industry 4.0 concepts. This ensures that the workforce remains competitive and capable of handling cutting-edge manufacturing processes.

Mexican companies of all sizes and capacities are implementing or are planning to implement AM technologies and are actively looking for both turn-key solution and assistance conceptualizing automated processes that could help them better meet their customers’ demands.

Few U.S. companies are leveraging the momentum of Mexico’s high degree of interest in AM, despite buyers’ preferences for U.S. made products. Supplier meetings are strategic to connecting with vetted reputable buyers.

Advanced manufacturing techniques and applications have exploded across a range of industry-sectors in Mexico.

Partnering With Local Suppliers in Mexico

Collaborating with local suppliers in Mexico offers numerous advantages specifically tailored to the electronics manufacturing industry. By partnering with nearby suppliers, companies can reap benefits such as decreased transportation costs, expedited response times, and improved communication channels. Proximity to suppliers enables efficient coordination and enhances flexibility in managing supply chain activities, crucial for meeting tight production schedules and minimizing delays.

For instance, electronics manufacturers in Mexico can benefit from working closely with local PCB fabrication companies. This proximity allows for streamlined logistics, reducing shipping times and costs associated with importing PCBs from distant locations. Additionally, when facing unexpected changes or urgent requirements, local suppliers can quickly respond and provide timely support, ensuring uninterrupted production processes.

How Companies Can Stay Agile in the Evolving Electronics Industry

The electronics industry is continually evolving, and keeping your business agile in this landscape ensures your competitiveness. Here's how:

Leverage flexible service models

Flexible operational models are crucial. These services allow businesses to adapt quickly to market shifts, whether that involves ramping up production or pivoting away from existing strategies.

Focus on Scalable Solutions

As demand fluctuates, scalable solutions are key. Technologies and services that grow with your company prevent resource wastage and ensure efficiency.

Embrace transparency and strategic guidance

Transparency in operations strengthens trust and alignment between all stakeholders. Ensure you have clear communication and strategic guidance to pave the way for informed decision-making and efficient operations.

Plan for Growth and Transition

Be prepared to expand or transition away from existing models as needed. This foresight enables smooth scaling or phasing out activities without disrupting workflow or profitability.

Conclusion

Streamlining the supply chain is crucial for successful electronics manufacturing in Mexico. By enhancing efficiency, reducing costs, and mitigating risks, manufacturers can gain a competitive edge in the industry. Embracing strategies such as supplier relationship management, JIT inventory management, technology integration, and continuous improvement ensures a streamlined and robust supply chain. Leveraging Mexico's strategic location and developing a skilled workforce further contribute to the success of electronics manufacturing in the country. Choosing a nearshore manufacturing partner like NovaLink in Mexico offers numerous benefits, including proximity to major markets, access to a skilled workforce, supply chain integration, and regulatory compliance.

FAQs:

- Q: What are the benefits of streamlining the supply chain in electronics manufacturing?

A: Streamlining the supply chain in electronics manufacturing offers benefits such as improved efficiency, cost savings, minimized risks, and enhanced quality control. - Q: How does just-in-time (JIT) inventory management contribute to supply chain optimization?

A: JIT inventory management reduces inventory levels, minimizes waste, and improves cash flow by receiving components and materials just when they are needed. - Q: What role does technology play in streamlining the supply chain?

A: Technology solutions such as automation, data analytics, and cloud-based systems enable real-time tracking, efficient planning, and collaboration, leading to a streamlined supply chain. - Q: Why is Mexico an attractive location for electronics manufacturing?

A: Mexico's strategic location, skilled workforce, and proximity to the United States make it an attractive location for electronics manufacturing due to reduced transportation costs and faster response times. - Q: How can collaboration with local suppliers benefit electronics manufacturers in Mexico?

A: Collaborating with local suppliers in Mexico reduces transportation costs, allows for better coordination, and strengthens the overall industry ecosystem, contributing to a streamlined supply chain.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into sourcing in Mexico with our curated collection of related blog posts.

- How Mexico Is Strengthening Supply Chains for Long-Term Stability

- Is Your Supply Chain Ready for a Mexico Move?

- How to Streamline Supply Chains in Mexico Without Losing Your Mind (or Your Margin)

- The Most Overlooked Advantage of Mexico’s Logistics Infrastructure

- Stop Wasting Time—These Are the Fastest Trade Routes in Mexico