Last Updated on February 27, 2024

When it comes to global manufacturing, few countries can match Mexico. With a rapidly growing economy, strategic geographical location, and a skilled labor force, Mexico has emerged as a manufacturing hub. However, in an era of heightened competition, maintaining cost competitiveness has become paramount. In this article, we delve into the factors and strategies that drive cost competitiveness in Mexican manufacturing. We unveil the secrets to success in this dynamic market.

Understanding the Landscape: Mexico's Manufacturing Advantage

Mexico's manufacturing story is compelling. Its proximity to the United States, one of the world's largest consumer markets, gives it a logistical edge. Additionally, the country boasts a well-trained workforce across various industries. Lower labor costs compared to developed nations further add to its attractiveness.

Factors Influencing Cost Competitiveness

Labor Costs and Skilled Workforce

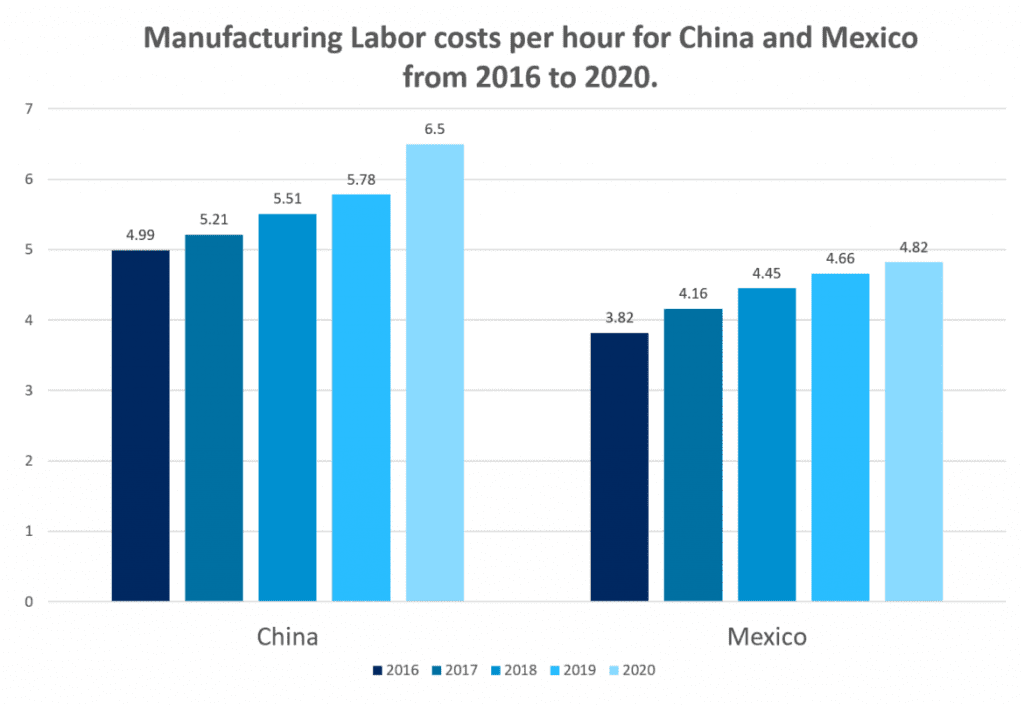

Mexico's labor costs, while higher than some Asian countries, remain significantly lower than those in the United States and Europe. This cost advantage is complemented by the country's skilled workforce, which contributes to higher productivity and quality output. Skilled engineers, technicians, and operators are a key driver of cost competitiveness.

Infrastructure and Logistics

Efficient infrastructure and logistics are the backbone of a competitive manufacturing sector. Mexico's well-developed transportation networks, including roads, ports, and railways, facilitate smooth goods movement within the country and across borders. This enhances supply chain efficiency and reduces costs.

Efficient infrastructure and logistics are the backbone of a competitive manufacturing sector. Mexico's well-developed transportation networks, including roads, ports, and railways, facilitate smooth goods movement within the country and across borders. This enhances supply chain efficiency and reduces costs.

Mexico - Country Commercial Guide

Trade Agreements and Market Access

Mexico's participation in trade agreements, such as the United States-Mexico-Canada Agreement (USMCA), grants manufacturers access to a broader market. Reduced trade barriers and tariffs translate into cost savings and competitive advantages, making Mexican products more attractive to international buyers.

Energy Costs and Sustainability

In recent years, Mexico has made strides in energy sector reforms. The availability of cost-effective and sustainable energy sources, including natural gas and renewable energy, helps manufacturers reduce operational costs. Embracing sustainable practices cuts expenses but also aligns with global environmental trends.

Strategies for Cost Competitiveness in Manufacturing

Lean Manufacturing and Process Optimization

Implementing lean manufacturing principles streamlines operations and minimizes waste. By identifying and eliminating inefficiencies, manufacturers can reduce costs while maintaining or enhancing product quality. This continuous improvement approach fosters a efficiency culture throughout the organization.

Supplier Collaboration and Local Sourcing

Collaboration with local suppliers reduces lead times and transportation costs. Proximity to suppliers allows more agile responses to demand fluctuations, reducing excess inventory. This strategy also bolsters the local economy, creating a win-win scenario.

Technology Adoption and Automation

Investing in cutting-edge technologies and automation systems for manufacturing yields substantial benefits in productivity enhancement and long-term reduction of labor costs. By integrating robotics, artificial intelligence, and data analytics into operations, manufacturing processes are optimized to their utmost potential. This strategic integration not only minimizes errors but also amplifies overall efficiency to unprecedented levels.

In recent years, the fields of robotics and automation have experienced remarkable advancements that are reshaping various industries. These innovations are not only changing the way we work and produce, but also expanding the possibilities of what can be achieved. Robotic systems have revolutionized manufacturing and production processes. Advanced robotic arms equipped with precise sensors and AI algorithms are capable of performing intricate tasks with unparalleled accuracy and speed. Automation of assembly lines has led to increased efficiency, reduced error rates, and higher production volumes.

Unleashing the Future: How Robotics and Automation are Reshaping Industries for Maximum Efficiency and Quality

Navigating Challenges for Sustainable Competitiveness

Currency Fluctuations and Market Volatility

Global market dynamics can impact currency values, affecting manufacturing costs. Manufacturers should implement hedge strategies and closely monitor economic trends to mitigate currency fluctuations risks.

Skills Gap and Workforce Development

As technology evolves, a skilled workforce becomes increasingly crucial. Addressing the skills gap requires investing in training and education programs that equip employees with the necessary expertise to operate advanced technologies effectively.

Conclusion: Mastering the Art of Cost Competitiveness

Mexico's manufacturing landscape offers abundant opportunities for businesses to thrive. By leveraging factors like a skilled workforce, efficient logistics, and favorable trade agreements, manufacturers can carve out a niche in the global market. Adopting strategies such as lean manufacturing, supplier collaboration, and technology integration empowers businesses to stay cost-competitive and sustain growth.

Frequently Asked Questions About Cost Competitiveness in Mexican Manufacturing

Q: How does Mexico's labor cost compare to other manufacturing hubs?

A: While higher than some Asian countries, Mexico's labor costs are considerably lower than those in the United States and Europe.

Q: What role does infrastructure play in Mexico's cost competitiveness?

A: Efficient infrastructure and logistics networks enhance supply chain efficiency, reducing costs for manufacturers.

Q: How do trade agreements benefit Mexican manufacturers?

A: Trade agreements like the USMCA reduce trade barriers and tariffs, making Mexican products more attractive to international buyers.

Q: What is the significance of automation in maintaining cost competitiveness?

A: Automation enhances productivity and efficiency, reducing labor costs and ensuring long-term competitiveness.

Q: How can manufacturers address the challenge of currency fluctuations?

A: Implementing hedging strategies and closely monitoring economic trends can help mitigate the impact of currency fluctuations on manufacturing costs.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.