Last Updated on February 27, 2024

In the fast-paced world of manufacturing, businesses constantly seek ways to streamline operations and minimize waste. One approach that has gained significant traction is Just-In-Time (JIT) manufacturing. JIT is not just a buzzword; it's a strategic philosophy that can revolutionize manufacturing processes. In this comprehensive guide, we'll delve deep into the five key principles of JIT manufacturing. We'll reveal why it's a seamless fit for Mexico's manufacturing industry.

What is JIT Manufacturing?

At its core, Just-in-Time (JIT) manufacturing is a strategic approach aimed at producing goods or components precisely when they are needed, in the right quantity, and without excess. It's about trimming waste and maximising productivity.

The JIT inventory system is popular with small businesses and major corporations alike because it enhances cash flow and reduces the capital needed to run the business. Retailers, restaurants, on-demand publishing, tech manufacturing, and automobile manufacturing are examples of industries that have benefited from just-in-time inventory.

Just-in-Time (JIT): Definition, Example, and Pros & Cons

Principle 1 - The Pull System

JIT began with a simple yet powerful concept – the Pull System. Instead of sticking to rigid production schedules, JIT manufacturing responds to customer demand. It's like preparing a meal when you're ready to eat it. This minimizes overproduction, reduces excess inventory, and allows manufacturers to adapt to market changes.

Principle 2 - Takt Time

Imagine a metronome guiding a musician's rhythm; that's Takt Time's role in JIT manufacturing. It sets the pace at which products should be produced to meet customer demand. This synchronizes production with actual requirements, ensuring a smooth and harmonious workflow.

Principle 3 - Continuous Flow

JIT's mantra is to keep the river flowing. Continuous flow ensures materials move seamlessly from one production stage to another, eliminating bottlenecks and delays. Like an orchestra, each component contributes to the efficiency of the system.

Principle 4 - The Kanban System

Picture a supermarket shelf that gets restocked precisely when items run low. That's the essence of the Kanban system in JIT. It uses visual signals to trigger the replenishment of materials or products, reducing waste and ensuring resources are employed only when needed.

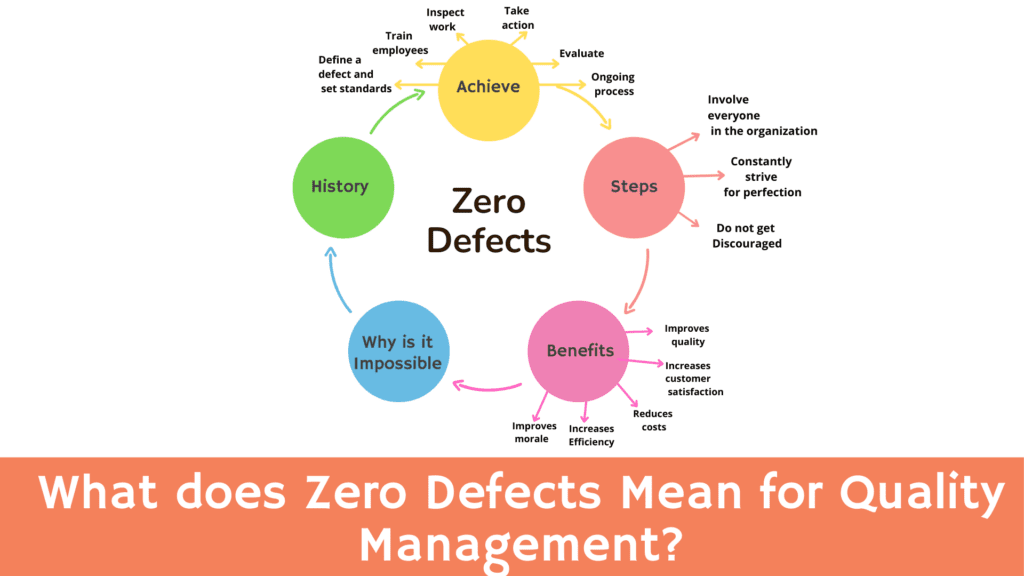

Principle 5 - Zero Defects

In JIT, perfection is the goal. The Zero Defects principle emphasizes stringent quality control. By addressing issues as they arise, JIT minimizes defects and slashes costly rework, ensuring products meet high standards.

Zero Defects in Quality Management

Why Just-in-Time Manufacturing Thrives in Mexico

Now, let's explore why JIT manufacturing is tailor-made for the thriving manufacturing sector in Mexico.

Strategic Location

Mexico's proximity to North America's vast consumer markets, particularly the United States, is a standout feature. This close geographical proximity significantly reduces transportation times and costs. For JIT manufacturing, which relies on efficient and timely delivery of components and finished products, this proximity is a game-changer.

Skilled Workforce

Mexico's commitment to education and vocational training, coupled with its cost-effective and culturally dedicated workforce, makes it a highly attractive location for JIT manufacturing. This skilled talent pool not only meets the technical demands of modern manufacturing but also aligns with the principles of efficiency, adaptability, and quality control that JIT manufacturing relies upon.

Cost-Efficiency

Cost efficiency is a hallmark of JIT manufacturing, and Mexico offers competitive labor and operating costs, making it an attractive destination for companies seeking to implement JIT practices.

Supply Chain Integration

The close integration of Mexico's manufacturing industry with its North American neighbors ensures a well-established supply chain. This aligns with JIT's need for seamless material flow.

Regulatory Environment

Mexico has made significant strides in creating a favorable business environment. Regulations and incentives encourage foreign investment and manufacturing operations, further supporting JIT implementation.

Conclusion

In conclusion, the five principles of Just-in-Time (JIT) manufacturing offer a path to heightened efficiency, reduced waste, and improved competitiveness. When combined with Mexico's strategic advantages, including its location, skilled workforce, cost-efficiency, supply chain integration, and business-friendly regulations, JIT becomes an even more compelling proposition for manufacturers. Mexico and JIT manufacturing are a harmonious duet, creating a success symphony.

Frequently Asked Questions on Just-in-Time Manufacturing and Mexico

FAQ 1: How does JIT manufacturing benefit Mexico's economy?

Answer: JIT manufacturing promotes economic growth in Mexico by attracting foreign investment, creating jobs, and fostering a vibrant manufacturing ecosystem.

FAQ 2: Can JIT manufacturing work for small businesses in Mexico?

Answer: Yes, JIT principles can be scaled to fit businesses of all sizes, including small enterprises in Mexico. It's about tailoring the approach to your specific needs.

FAQ 3: Are there any cultural considerations in implementing JIT manufacturing in Mexico?

Answer: Cultural sensitivity and effective communication are crucial when introducing JIT practices in Mexico to ensure buy-in from the local workforce.

FAQ 4: What industries in Mexico benefit most from JIT manufacturing?

Answer: JIT principles can be applied across various industries, but automotive, electronics, aerospace, and medical devices are among those that particularly benefit from JIT in Mexico.

FAQ 5: What support does the Mexican government provide to companies implementing JIT manufacturing?

Answer: The Mexican government offers incentives and support programs to encourage JIT manufacturing and foreign investment, making it easier for companies to adopt JIT practices.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.