Last Updated on February 26, 2024

In today's competitive business landscape, efficiency is no longer a luxury - it's a necessity. For Mexican companies, this is especially true. With rising labor costs and an increasingly demanding customer base, businesses need to streamline their operations and improve their bottom line. One solution that can help companies achieve this is kitting services. Kitting involves the pre-assembly of individual components into a kit, which is then ready for immediate use. This eliminates the need for workers to gather individual parts, saving time and labor costs.

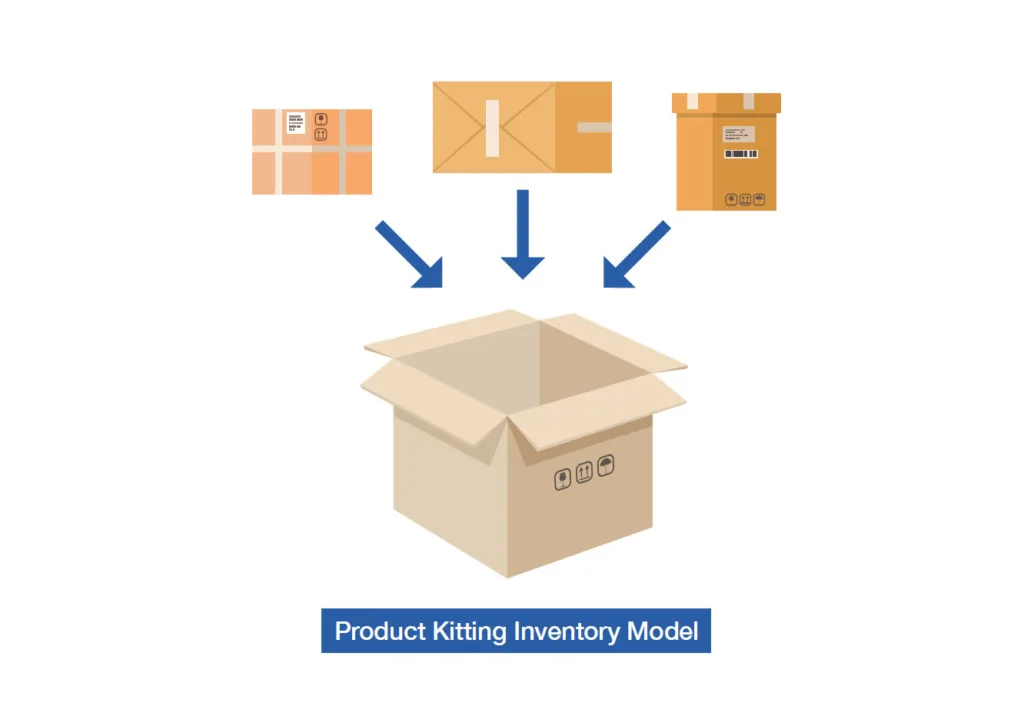

Understanding Kitting Services

Before delving into the impact of kitting services, let's demystify the concept. In simple terms, kitting involves bundling together related items sold as a single unit. This process streamlines order fulfillment, enhancing efficiency and reducing operational costs. In Mexico, where markets thrive on agility, kitting services have emerged as a game-changer for businesses looking to stand out.

Manufacturing Industries That Benefit From Kitting Services

In the manufacturing sector, kitting services play a crucial role in improving efficiency, reducing errors, and streamlining production processes. Here are some specific manufacturing industries that benefit from kitting services:

- Automotive Manufacturing: Kitting is used to assemble specific components for vehicles, ensuring that the right parts are readily available at each stage of production.

- Electronics Manufacturing: In the electronics industry, kitting is employed to assemble components for devices, circuit boards, and other electronic products.

- Aerospace Manufacturing: Kitting is vital in aerospace manufacturing for assembling complex components and ensuring part accuracy in the production of aircraft and spacecraft.

- Medical Device Manufacturing: Kitting is utilized to assemble components for medical devices, ensuring precision and compliance with regulatory requirements.

- Industrial Equipment Manufacturing: Manufacturers of industrial machinery and equipment benefit from kitting for assembling complex assemblies and ensuring all necessary parts are available.

- Consumer Electronics Manufacturing: Kitting is used in the assembly of consumer electronic products, such as smartphones, tablets, and other gadgets.

- Appliance Manufacturing: Appliance manufacturers use kitting to assemble components for refrigerators, washing machines, and ovens.

- Textile and Apparel Manufacturing: Kitting is applied in the textile and apparel industry for bundling and packaging clothing items and accessories.

What is the Difference Between Kitting and Bundling?

Kitting and bundling are both inventory management and packaging strategies, but they involve different processes and have distinct purposes. While both kitting and bundling involve grouping items together, kitting is more about assembling components for a specific purpose. This is often in a manufacturing context. Bundling is the process of combining products for sale or promotional purposes, typically in retail or e-commerce settings.

Kitting and bundling are similar concepts, but they are not identical. A kit is composed of a combination of different items, like a gift set that may include different knives and a cutting board. A bundle, on the other hand, contains multiple quantities of the same item.

Listing Mirror

How Kitting Services Can Help Your Company Compete

In manufacturing's competitive business environment, kitting services can give your company a edge. By streamlining your operations and improving your efficiency, you can:

- Reduce your costs: Lowering labor and inventory costs can improve your bottom line and make you more competitive.

- Improve your responsiveness: With faster order fulfillment, you can respond to customer orders faster and efficiently.

- Increase your flexibility: Kitting can make your production process more flexible, allowing you to easily adapt to demand changes.

- Enhance your quality: By reducing errors in the assembly process, you can improve your products' quality.

- Boost customer satisfaction: Faster, more accurate order fulfillment can lead to happier customers.

Choosing the Right Kitting Service Provider

When considering kitting services in Mexico, choosing the right provider is crucial to your success and efficiency. Here are some factors to consider when selecting a kitting services provider in Mexico:

- Experience and Expertise: Look for a provider with a proven track record in kitting services. Experience of handling similar projects in your industry is valuable.

- Facility Capabilities: Assess the provider's facilities to ensure they have the necessary infrastructure, technology, and equipment to handle your specific kitting requirements.

- Quality Assurance: Check if the provider has robust quality control measures in place. Ensure that they follow industry standards and regulations to maintain assembled kits' quality.

- Customization and Flexibility: Choose a provider that tailors kitting services to meet your specific needs. Flexibility is essential for accommodating changes in product configurations or assembly processes.

- Scalability: Consider the provider's ability to scale their operations to meet your production demands. This is especially critical if your business experiences demand fluctuations.

- Supply Chain Integration: A kitting services provider should seamlessly integrate into your supply chain. Ensure they have effective communication and coordination processes to avoid disruptions.

- Location: Evaluate the provider's Mexico location. Proximity to manufacturing facilities or distribution centers can reduce transportation costs and lead times.

- Cost Competitiveness: Compare kitting costs among different providers. Ensure that the pricing structure is transparent and competitive without compromising quality.

- Technology and Automation: Assess the provider's use of technology and automation in kitting processes. Advanced technologies can improve accuracy, efficiency, and overall performance.

- Compliance and Regulations: Verify that the kitting services provider complies with local regulations and international standards. This is particularly relevant in industries with strict regulatory requirements.

- Communication and collaboration: Strong communication is crucial. Choose a provider that maintains open and transparent communication channels, keeping you informed about your kitting projects.

- References and Reviews: Seek references from other clients who have used the provider's kitting services. Online reviews and testimonials can reveal the provider's reputation.

- Sustainability Practices: Consider the provider's sustainability commitment. Assess their environmental practices and whether they align with your company's sustainability goals.

- Insurance and Risk Management: Ensure that the provider has appropriate insurance coverage and risk management strategies in place to mitigate potential issues or losses during the kitting process.

- Timeliness and Turnaround: Assess the provider's ability to meet deadlines and provide quick turnaround for kitting projects. Timely delivery is critical for efficient supply chain operations.

Benefits of Kitting Services in Mexico

Kitting services in Mexico can be a strategic solution for businesses looking to optimize their supply chain, reduce costs, and improve operational efficiency.

- Competitive labor costs: Mexico offers skilled labor at lower rates compared to many other countries.

- Government incentives: Mexico provides various incentives for manufacturers and logistics providers, including tax breaks and duty-free imports.

- Free trade agreements: Mexico has free trade agreements with many countries, including the US, which can further reduce your costs and improve market access.

Conclusion

By using kitting services, companies operating in Mexico can streamline their operations, reduce costs, and improve their competitiveness. If you're looking for ways to improve your business, outsourcing kitting services can be a valuable strategy.

FAQs About Kitting Services:

1. What types of products can be kitted?

A large variety of products can be kitted, including automotive parts, electronics, medical devices, and consumer goods.

2. How much do kitting services cost?

The cost of kitting services will vary depending on the size and complexity of the kits, the volume of kits required, and the location of the provider.

3. How can I find a kitting service provider in Mexico?

There are a number of online directories and industry associations that can help you find kitting service providers in Mexico.

4. What are the risks of using kitting services?

One risk of using kitting services is that the provider may not be able to meet your quality standards. It's important to carefully evaluate potential providers before making a decision.

5. What are the alternatives to kitting services?

Some alternatives to kitting services include outsourcing assembly to a contract manufacturer or assembling products on-demand. However, these options may not be as efficient or cost-effective as kitting services.

By carefully considering the benefits and risks of kitting services, you can decide if they are the right solution for your company.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.