Last Updated on April 2, 2024

Nearshoring has become a buzzword in the business world, and Texas and Mexico are leading the charge. The two regions partner in a harmonious supply chain symphony, leveraging their geographical proximity and economic strengths. Texas and Mexico are partnering in nearshoring, forging a strategic alliance that promises to reshape global supply chains.

The Global Trade Landscape

Change winds are blowing through the international trade landscape. The traditional model of distant manufacturing hubs being challenged is driven by a multitude of factors, including:

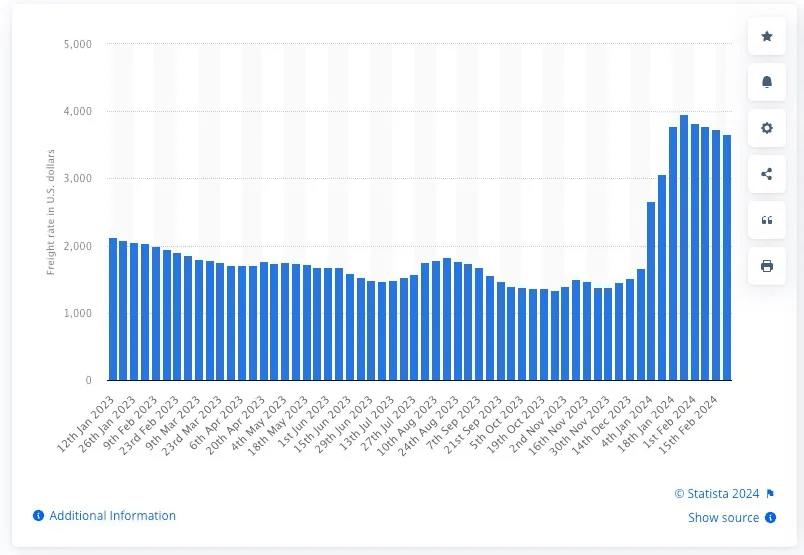

- Rising transportation costs: Global shipping costs have skyrocketed in recent years, making distant production less cost-effective.

- Supply chain disruptions: The COVID-19 pandemic exposed long, complex supply chains' vulnerabilities, prompting companies to seek greater control and proximity.

- Geopolitical tensions: Trade tensions and political instability are leading companies to diversify their sourcing strategies and reduce reliance on one country.

Statista: Global container freight rate index from the 12th January 2023 to the 22nd February 2024

Texas and Mexico: A Match Made in Nearshoring Heaven

In this dynamic environment, Texas and Mexico have emerged as key players in the nearshoring game. Their geographical proximity, complementary strengths, and long-standing economic ties make them a natural fit for nearshoring partnerships.

Shifting global supply chains in Mexico, increasing cross-border trade and a business-friendly climate in the region are helping the Lone Star State outpace California in population growth and gross domestic product, experts said.

Freight Waves

Mexico's Advantages

Mexico boasts a skilled and competitive workforce, with a growing middle class that represents a significant consumer market. The country has also made significant strides in improving its infrastructure, including transportation networks and logistics capabilities.

Texas' Strengths

Texas, on the other hand, offers a business-friendly environment, with low taxes, a deregulated economy, and a robust infrastructure. The state also boasts a strong logistics network, including major ports and airports, that facilitate efficient goods movement.

The state of Texas exports the most goods to Mexico, including plastics, chemicals, computers and electronics, and machinery. Many American manufacturers have opened factories and production facilities in northern Mexican states due to lower wages and proximity to Texas ports.

A Symphony of Collaboration

Together, Texas and Mexico are creating a nearshoring symphony, with each partner playing a vital role in the whole's success.

The Texas-Mexico Nearshoring Partnership Offers Several Advantages

- Reduced transportation costs: Shorter distances between production and consumption points translate into significant shipping savings.

- Enhanced supply chain resilience: Nearshoring reduces reliance on distant suppliers, making supply chains less susceptible to disruptions.

- Increased agility and responsiveness: Closer proximity allows companies to respond faster to market changes and customer demands.

- Creation of jobs and economic growth: Both Texas and Mexico stand to benefit from new jobs and economic opportunities driven by nearshoring.

Conclusion: Texas and Mexico Are Partnering in Nearshoring and Demonstrating the Power of Collaboration

Texas and Mexico are partnering in nearshoring and are a compelling example of how collaboration can lead to mutually beneficial outcomes. By leveraging their unique strengths and geographical proximity, these two economic powerhouses are poised to play a leading role in shaping global trade's future.

FAQs (Frequently Asked Questions): Texas and Mexico are Partnering in Nearshoring

1. How does nearshoring differ from offshoring? Nearshoring involves outsourcing to nearby countries, often with shared borders, while offshoring typically entails outsourcing to distant countries, often across oceans.

2. What industries benefit most from nearshoring between Texas and Mexico? Industries such as manufacturing, automotive, aerospace, electronics, and consumer goods benefit significantly from nearshoring between Texas and Mexico due to lower costs and enhanced logistics.

3. Are there any risks associated with nearshoring to Mexico? While nearshoring offers numerous benefits, potential risks include political instability, regulatory changes, security concerns, and fluctuations in currency exchange rates.

4. How can companies navigate cultural differences when nearshoring to Mexico? Companies can navigate cultural differences by investing in cross-cultural training, fostering open communication channels, building strong relationships with local partners, and respecting cultural norms and customs.

5. What steps can companies take to ensure compliance with trade regulations and agreements? To ensure compliance, companies should stay informed about relevant trade regulations, engage legal and regulatory experts, implement robust compliance protocols, and maintain transparent record-keeping practices.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about Texas and Mexico manufacturing with our curated collection of related blog posts.

- Top 10 Reasons to Move Your Manufacturing Operations to Mexico

- Strengthening Your Supply Chain: How Texas Manufacturing Companies Benefit from Mexican Partnerships

- Maximizing the USMCA Advantage: Texas Manufacturers Partnering with Mexico

- Closer to Home: Why Texas is a Prime Location for Nearshoring Manufacturing

- Strategic Shifts: Texas Manufacturing Companies and the Nearshoring Movement