Last Updated on January 17, 2025

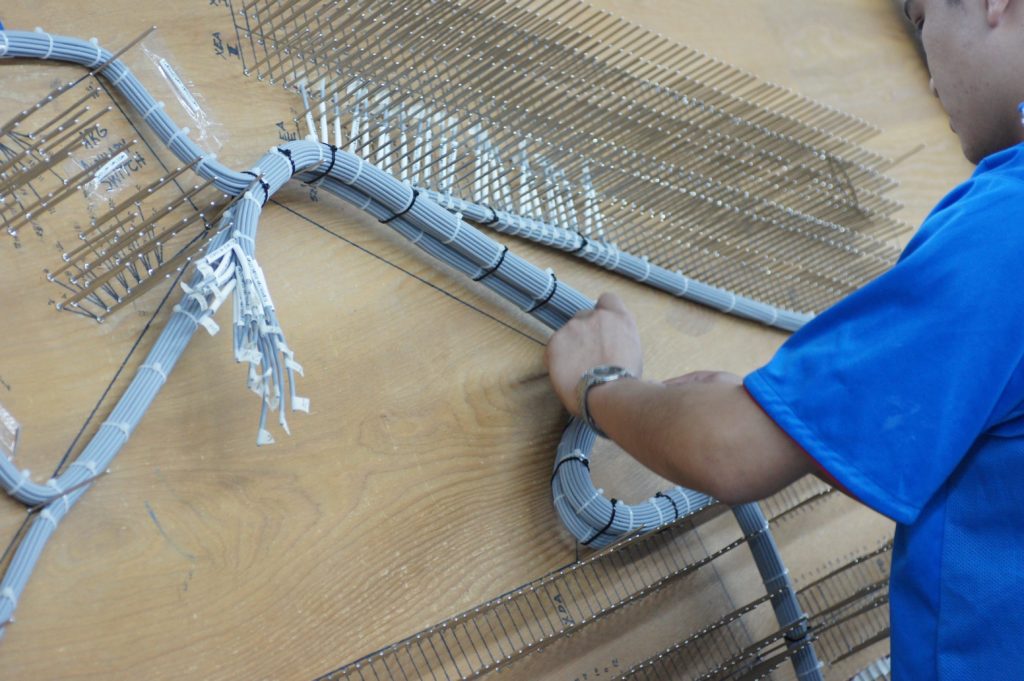

In today's globalized world, companies constantly seek ways to optimize their manufacturing processes. For many, wire harness assembly presents an exciting opportunity. Wire harnesses, the intricate networks of wires that act as the nervous system of electronic devices, require a skilled touch and a keen eye for detail. That's where Mexican wire harness assembly partners come in.

Mexico offers a compelling set of factors that make it an attractive location for wire harness assembly. Skilled labor, competitive costs, and geographical proximity to the US market are just a few reasons why many companies look south of the border. But finding the right partner can feel daunting. Worry not, this guide will equip you to find the right Mexican wire harness assembly partner for your needs.

The wire harness market is expected to register an incremental growth value of US$ 56.5Bn during (2023-2030). Technological advancements in food and beverage, agriculture and automobiles sectors are providing to provide opportunities for the global market growth during 2023-2030.

Insight Partners

Key Considerations for Selecting the Right Partner

Experience Reigns Supreme: Just like entrusting your car to a seasoned mechanic, your wire harness assembly partner should boast a proven track record. Look for companies with a history of success in your industry. Their experience translates into a deeper understanding of your product's unique challenges and requirements.

Quality is Uncompromising: A single faulty wire can bring your entire operation to a standstill. Ensure your potential partner adheres to rigorous quality control standards and has a documented inspection process. Certifications like ISO 9001 are a strong indicator of their quality commitment.

Communication is Critical: A successful partnership thrives on clear and consistent communication. Does the potential partner have a dedicated team that can effectively communicate in your preferred language? Time zone differences can be a hurdle, so inquire about their communication protocols and preferred methods of contact.

Flexibility is Essential: The manufacturing landscape is rarely static. Your needs may evolve over time. Does the potential partner have the flexibility to adapt to changes in your production volume or design specifications?

Look Beyond the Basics: While cost is certainly a factor, it shouldn't be the sole deciding element. Look for a partner who offers additional value-added services, such as prototyping, inventory management, or logistics support. These additional offerings can streamline your operations and free up your resources to focus on your core competencies.

Building a Strong Partnership: Finding the right partner is just the first step. Investing time and resources in building a strong relationship will reap significant rewards in the long run. Open communication, regular progress updates, and a collaborative approach will foster trust and ensure a successful partnership.

NovaLink's Comprehensive Range of Wire Harness Manufacturing Services

NovaLink offers a comprehensive range of wire harness manufacturing services. With expertise in the field, NovaLink delivers tailored solutions to meet diverse customer needs. Some of the key services provided by NovaLink include:

Wire Harness Design

NovaLink's experienced engineers collaborate closely with clients to design customized wire harnesses that meet specific requirements. By leveraging their knowledge of industry standards and best practices, they ensure optimal performance and reliability.

Wire Cutting and Stripping

NovaLink utilizes cutting-edge equipment to precisely cut and strip wires, ensuring accurate lengths and consistent quality. This step is crucial for achieving proper connectivity and electrical performance in wire harnesses.

Terminal Crimping

Skilled technicians at NovaLink expertly crimp terminals onto wires, creating secure and reliable connections. This process is essential for guaranteeing the integrity and longevity of the wire harnesses.

Connector Assembly

NovaLink specializes in the assembly of various types of connectors, including complex multi-pin connectors. Their technicians ensure proper alignment and mating of connectors to achieve seamless integration within electrical systems.

Custom Labeling and Packaging

NovaLink provides custom labeling and packaging solutions to meet specific branding and logistical requirements. Proper labeling ensures easy identification and installation of wire harnesses, while tailored packaging ensures safe transportation and storage.

Value-added Services

In addition to wire harness manufacturing, NovaLink offers value-added services such as prototyping, kitting, and supply chain management. These services further streamline the manufacturing process and provide comprehensive solutions to clients.

Harness Testing and Inspection

NovaLink implements rigorous testing and inspection procedures to verify the functionality and quality of wire harnesses. This includes continuity testing, insulation resistance testing, and visual inspections to detect any potential defects or issues.

Conclusion: Partnering With a Qualified and Reliable Mexican Wire Harness Assembly Company

Wire harness assembly is a critical component of many electronic devices. By partnering with a qualified and reliable Mexican wire harness assembly company, you can benefit from cost savings, skilled labor, and geographical proximity to the US market. Remember, the key to success lies in finding the right partner who aligns with your specific needs and fosters a collaborative working environment.

FAQs on Mexican Wire Harness Assembly

Bold the questions and answer them in normal font

Q: Is a Mexican wire harness assembly an appropriate fit for my company?

A: If you're looking to optimize your manufacturing processes and benefit from cost reductions, Mexican wire harness assembly could be an excellent option. However, it's imperative to carefully evaluate your needs and ensure a potential partner has the experience and capabilities to meet them.

Q: What are the biggest challenges of working with a Mexican wire harness assembly partner?

A: Communication and cultural differences can pose challenges. However, by choosing a partner with a strong track record of working with US companies and clear communication protocols, these hurdles can be easily overcome.

Q: How can I ensure the quality of my wire harness assembled in Mexico?

A: Look for a partner with certifications like ISO 9001 and a documented quality control process. Regular audits and clear communication of quality expectations are also crucial.

Q: What are the typical costs associated with Mexican wire harness assembly?

A: Costs vary depending on design complexity, material prices, and labor rates. Mexican wire harness assembly generally offers significant cost advantages over domestic options.

Q: What happens if I need to change my wire harness design mid-production?

A: A flexible partner can adapt to changes in your design specifications. Discuss your company's change order process upfront to ensure a smooth transition.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.