Last Updated on May 2, 2024

As global supply chains evolve, Mexican factories deliver a beacon of hope for businesses seeking efficiency and reliability. The maquiladora industry, which emerged in the 1960s, has undergone a significant transformation, embracing cutting-edge technology and innovative practices. Mexican factories are at the forefront of modern manufacturing, offering streamlined supply chains.

The Evolution of the Maquiladoras

Maquiladoras, initially established to assemble and export goods, have adapted to changing market demands. These factories have invested heavily in advanced machinery, automation, and workforce training, enabling them to produce high-quality products with increased precision and speed. This transformation has enabled Mexican factories to stay competitive, attracting international companies seeking reliable partners.

Streamlining Supply Chains

Mexican factories deliver a streamlined future for supply chains by:

- Reduced lead times: Strategic locations and efficient logistics enable quick turnaround times, getting products to market faster.

- Improved quality control: Advanced technology and rigorous quality standards ensure consistent, high-quality products.

- Offering flexibility: Scalable production capabilities and adaptable workflows accommodate fluctuating demand.

- Being Cost-Effective: While labor costs in Mexico are rising, they remain competitive compared to developed economies. Additionally, Mexico offers tax breaks and investment incentives for manufacturers, further lowering operational costs

Embracing Innovation

Mexican factories are at the forefront of innovation, embracing a shift towards innovation and technological advancement.

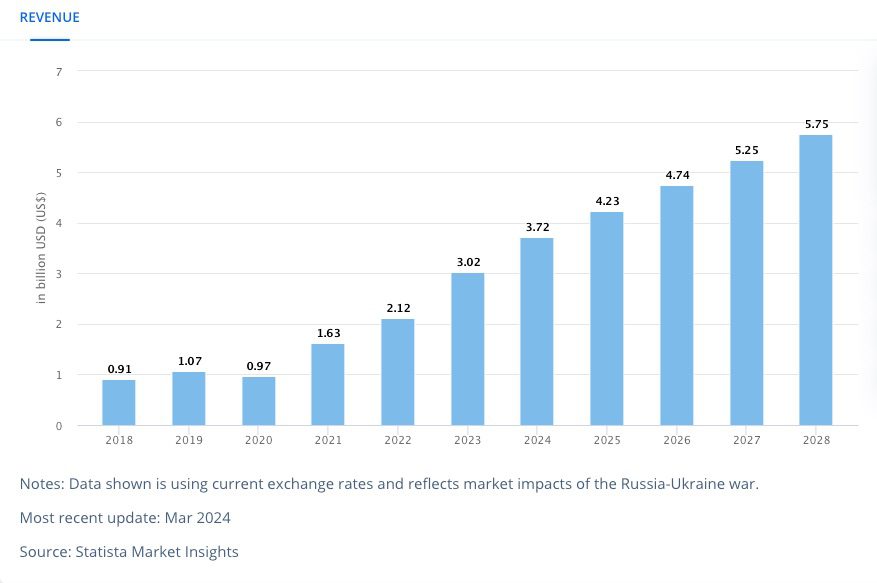

Source: Statitia. "Mexico is expected to see a significant growth in revenue within the Industrial IoT market."

Here's a breakdown of why this is happening:

- Tech Embrace: Mexican factories actively adopt technologies like robotics, artificial intelligence (AI), and the Internet of Things (IoT). This streamlines production, improves quality control, and keeps them competitive on a global market.

- Advanced Techniques: Beyond automation, Mexico is seeing a rise in advanced materials and manufacturing techniques. This includes things like composite materials and 3D printing, allowing for lighter, stronger, and even customized products.

- Government Push: The Mexican government invests in fostering innovation. They're investing in education and training programs to create a skilled workforce capable of handling these cutting-edge technologies. This creates a strong foundation for future advancements.

- Impact: The results are promising. Mexican factories are not just keeping pace, they're setting high standards for efficiency and productivity across various sectors, from automotive to aerospace.

But what about Mexico? As a center for conventional and advanced manufacturing for North America, Mexico has made progress in adopting the technologies required by Industry 4.0. Many of the world’s leading manufacturers have operations in Mexico, especially in industries such as automotive, electronics, aerospace, and medical instruments, which has favored the fact that given its location in the country, Mexican talent is increasingly immersed and specialized in new technologies such as robotics and IoT to improve efficiency, quality, and flexibility.

Institute for Democracy and Innovation

Conclusion: Mexican Factories Have Come a Long Way

Mexican factories have come a long way from their maquiladora roots, emerging as modern marvels of efficiency and innovation. As global supply chains continue to evolve, these factories are poised to deliver a streamlined future, offering businesses a competitive edge in an increasingly complex market.

Frequently Asked Questions on Mexican Factories

1. What are maquiladoras?

Maquiladoras are Mexican factories that assemble and export goods, initially established in the 1960s.

2. How have Mexican factories evolved?

Mexican factories have invested in advanced technology, automation, and workforce training, enabling them to produce high-quality products with increased precision and speed.

3. What benefits do Mexican factories offer to supply chains?

Mexican factories deliver reduced lead times, improved quality control, and flexibility, streamlining supply chains.

4. What innovative technologies do Mexican factories embrace?

Mexican factories adopt Industry 4.0 technologies, sustainable practices, and collaborative robots to enhance productivity and efficiency.

5. Why should businesses partner with Mexican factories?

Businesses can diversify their supply chain, improve product quality, and increase efficiency by partnering with Mexican factories.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about Mexico Manufacturing Facilities with our curated collection of related blog posts.

- Why Mexico Isn’t a Perfect Manufacturing Solution (and What That Really Means)

- Can Moving Manufacturing to Mexico Really Be Turnkey? Here’s What You Need to Know

- Setup Process for Manufacturing in Mexico: What You Should Know About Timelines, Permits, and Common Pitfalls

- Americans Say They Want More U.S. Factory Jobs—So Why Don’t They Want to Work in Them?

- Top 10 Well-Known American Companies in Mexico—Should You Be Next?

- Why Factories in Mexico Are the Preferred Choice for Nearshoring

- 5 Easy Steps to Move Your Production to a Mexican Factory

- 3 Key Benefits of Operating in Mexico’s Border Zone