Last Updated on November 27, 2024

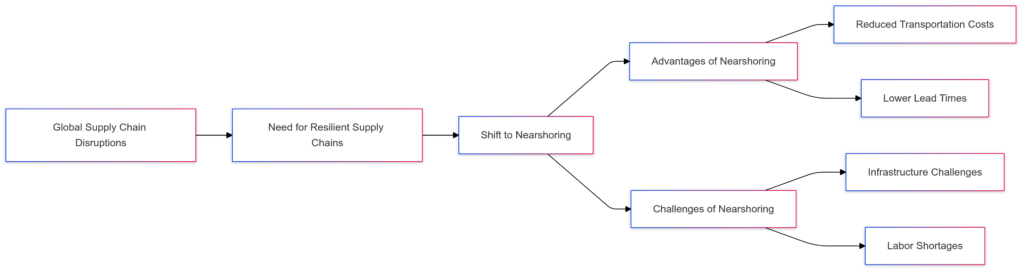

The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting industrials to reassess their operational resilience. Companies prioritize agility, flexibility, and resilience in their supply chain networks. This shift has led to increased demand for industrial relocation and supply chain restructuring. This article delves into the drivers behind nearshoring, its impact on the manufacturing sector, and the investment opportunities it presents.

Key Drivers for Nearshoring in North America

1. Supply Chain Disruptions and Geopolitical Tensions

Recent years have underscored the vulnerabilities of global supply chains. Geopolitical uncertainties, along with economic and environmental disruptions, have forced companies to reassess their reliance on distant suppliers. Nearshoring provides a solution to these issues by allowing businesses to reduce lead times, enhance flexibility, and mitigate risks associated with distant production hubs.

2. Cost Benefits and Technological Advancements

While the cost advantage of manufacturing in regions like China has declined, nearshoring to Mexico or other North American locations offers favorable conditions. Automation, robotics, and AI-driven systems offset labor costs, making North American production increasingly competitive. Government incentives, such as the CHIPS Act and the Inflation Reduction Act, further bolster these transitions by subsidizing domestic manufacturing and technology investments.

3. Sustainability and Customer Proximity

Consumers increasingly demand environmentally sustainable products, pushing companies to adopt greener practices. Nearshoring aligns with sustainability goals by reducing transportation emissions and supporting local economies. Moreover, proximity to key markets ensures better responsiveness to consumer demands and trends, fostering improved customer relationships.

Beyond addressing trade disruptions, reshoring and nearshoring could also offer significant benefits related to sustainability. One of the most notable advantages is the inherent reduction in carbon footprints, achieved by minimising the distances that goods need to travel. By relocating production facilities closer to end markets, businesses can lower greenhouse gas emissions, resulting in a more sustainable and efficient operation. - RSM Global

4. Relocation Trends

Regionalization has become a significant trend, with businesses establishing localized supply chains to cater to specific markets or regions. This shift is also evident in the movement of industries from urban centers to rural areas. This is where they can benefit from lower operational costs and improved accessibility. Furthermore, strategic proximity is a major factor, as companies strategically position themselves near key customers, suppliers, or transportation hubs.

Supply Chain Restructuring Strategies

Effective supply chain restructuring involves several strategies. Dual sourcing has become essential, with companies engaging multiple suppliers for critical components to mitigate risk. Inventory optimization is also crucial, with businesses implementing just-in-time inventory management and buffer stock to ensure continuity. Furthermore, digitalization plays a vital role, with industrials investing in supply chain visibility tools, predictive analytics, and automation to enhance agility and responsiveness.

Challenges in Implementing Nearshoring Strategies

Despite its advantages, nearshoring presents certain challenges. These include:

- Infrastructure Development: North American infrastructure must adapt to accommodate increased industrial activity.

- Labor Shortages: The shortage of skilled labor in some regions could impact nearshoring speed and scalability.

- Transition Costs: Relocating production facilities involves capital investments, which may not yield immediate returns.

Key Sectors Benefiting from Nearshoring

1. Automotive and Electronics

Automotive manufacturing, especially electric vehicles (EVs) and battery production, benefits from nearshoring. Given the complexity of EV supply chains, companies gain an advantage by relocating these activities to North America. Likewise, electronics manufacturing, including semiconductors, is reshoring due to government incentives aimed at strengthening national security and technological self-sufficiency.

2. Industrial Machinery and Components

As U.S. industries require machinery and components critical to industrial operations, onshoring supply chains has become crucial. Mexico, with its skilled workforce and proximity, provides a compelling location for manufacturing these goods. This sector is set to expand further as companies prioritize local manufacturing to reduce import dependency.

3. Renewable Energy

With the global shift toward sustainability, the renewable energy sector will benefit from nearshoring. Demand for wind turbines, solar panels, and energy storage solutions has risen, with Mexico positioned as a strategic hub for their production. Nearshoring allows companies to leverage advanced manufacturing practices while tapping into local green energy expertise.

Benefits of Mexico Relocation

Mexico is emerging as an attractive destination for supply chain relocation. Its proximity to the US market reduces transportation costs and times, enhancing supply chain efficiency. Mexico's skilled workforce, competitive labor costs, and established manufacturing infrastructure also make it an ideal location. Additionally, the USMCA (United States-Mexico-Canada Agreement) provides a favorable trade framework, streamlining cross-border commerce. By relocating supply chains to Mexico, companies can leverage these advantages to improve resilience, reduce costs, and enhance competitiveness.

Private Equity Perspective on Supply Chain Restructuring

Supply chain restructuring and industrial relocation are areas in which private equity firms see opportunities. By investing in strategic technology, these companies support digital transformation and supply chain modernization.

The private equity firms also provide operational expertise, including advice on reducing costs and improving efficiency. In addition to strategic acquisitions, targeted acquisitions facilitate consolidation and expansion.

Nearshoring Investment Opportunities

The nearshoring trend is creating investment opportunities across various sectors:

- Automation and Robotics: Companies in these sectors benefit by providing the technology needed to optimize North American manufacturing.

- Logistics and Warehousing: Proximity to the end markets demands robust logistics networks, opening opportunities for investors in transportation and warehousing.

- Private Equity in Industrial Manufacturing: Private equity firms are increasingly targeting companies that enable nearshoring, supporting growth through technology, advanced manufacturing, and process automation.

Conclusion

Industrial relocation and supply chain restructuring have become essential strategies for companies seeking resilience and agility. As businesses navigate this new landscape, private equity firms are poised to support growth and transformation.

Frequently Asked Questions

What are the primary drivers of supply chain restructuring?

The primary drivers include nearshoring and reshoring, supply chain diversification, and operational efficiency.

How can companies benefit from relocating supply chains to Mexico?

Companies can leverage Mexico's proximity to the US market, skilled workforce, competitive labor costs, and established manufacturing infrastructure to improve resilience, reduce costs, and enhance competitiveness.

What role does digitalization play in supply chain restructuring?

Digitalization enhances supply chain visibility, predictive analytics, and automation, enabling companies to respond swiftly to disruptions and changes.

What are the key challenges associated with supply chain restructuring?

Talent acquisition and retention, infrastructure and logistics, and sustainability and ESG considerations are significant challenges.

How can private equity firms support supply chain restructuring?

Private equity firms provide strategic investments in technology, operational expertise, and guidance on efficiency improvements and cost reduction, facilitating consolidation and expansion through targeted acquisitions.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about Mexico Supply Chain with our curated collection of related blog posts.

- How Mexico Is Strengthening Supply Chains for Long-Term Stability

- How to Find Your Ideal Mexico Manufacturing City

- Is Your Supply Chain Ready for a Mexico Move?

- Mexico’s Customs Clearance: Why It’s Faster—and Smarter—for Manufacturers

- How to Streamline Supply Chains in Mexico Without Losing Your Mind (or Your Margin)

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.