Last Updated on November 21, 2024

TL;DR

Agile manufacturing, which focuses on flexibility and responsiveness, is essential for companies navigating fast-changing markets and consumer demands. Mexico is an ideal location for agile manufacturing due to its strategic geographic position, skilled and cost-effective workforce, and supportive trade agreements like USMCA. Manufacturers in Mexico excel in rapid prototyping, streamlined supply chains, scalable production, and advanced technologies, giving businesses a competitive edge. By choosing Mexico, companies can reduce costs, speed up time-to-market, and adapt seamlessly to market shifts—future-proofing their operations for success.

Introduction

Adapting to consumer demands and unpredictable market conditions can be challenging in today's fast-paced global economy. Mexico Agile Manufacturing offers a powerful solution for companies seeking to optimize their operations. Mexico's strategic location, skilled workforce, and supportive business environment have made it a hub for agile manufacturing.

What is Agile Manufacturing?

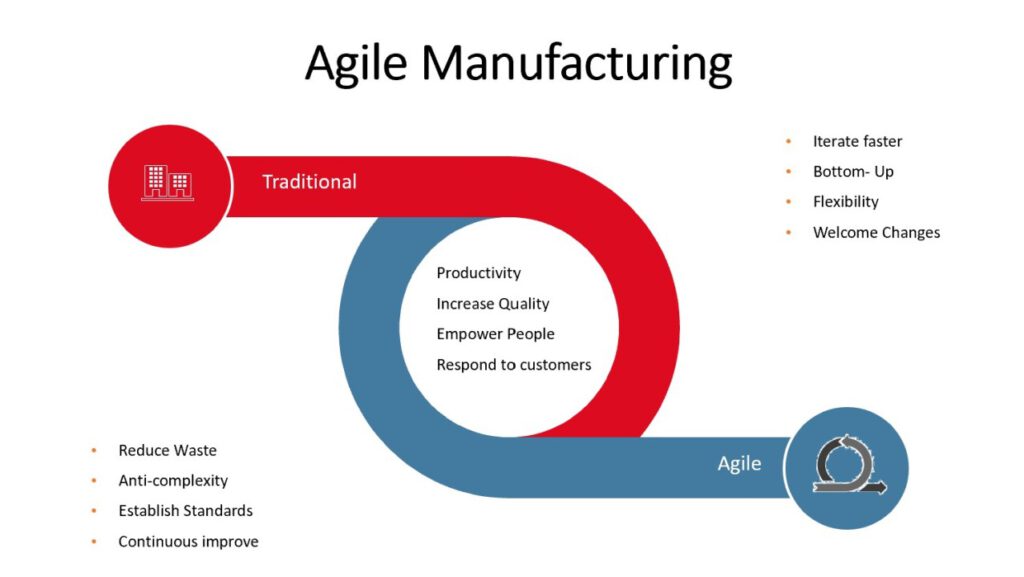

Agile manufacturing is a production philosophy centered on flexibility and responsiveness. It’s not just about making products quickly—it’s about making the right products at the right time. Think of it as a well-oiled machine that can change direction on a dime, whether it’s switching product lines, adjusting volumes, or responding to new market trends.

Why is this significant? Because businesses today don’t have long lead times or static production schedules. Markets evolve rapidly, and consumer expectations are higher than ever. Agile manufacturing is the answer to staying competitive.

Why Mexico Is Ideal for Agile Manufacturing

1. Strategic Location for Global Access

Located between North and South America, Mexico is a gateway to global trade. Its proximity to the United States—the world’s largest economy—allows manufacturers to deliver products faster and cheaper. Add to that its robust port infrastructure, and Mexico becomes a linchpin for efficient supply chains.

2. A Skilled and Cost-Effective Workforce

Mexico boasts a large, highly trained workforce specializing in automotive, electronics, and textiles. Labor costs are competitive, but value extends beyond price. Mexico workers are known for their adaptability and technical expertise, which are key to agile manufacturing.

3. Supportive Trade Agreements

Through agreements like the USMCA (United States-Mexico-Canada Agreement), Mexico ensures tariff-free access to key markets. These agreements provide manufacturers with the flexibility to pivot quickly, whether responding to shifts in consumer preferences or adapting to new trade dynamics.

How Mexico Agile Manufacturing Responds to Dynamic Demand

Rapid prototyping and customization

Mexico manufacturers excel at rapid prototyping, allowing businesses to test and refine products before full-scale production. This capability is critical when consumer preferences change quickly. Need a custom design or a limited-run product? Mexico has the expertise to deliver.

The Mexico Rapid Prototyping market is believed to see growth at a CAGR of 19.3% during the projected period, with a market size of USD 113.76 million in 2024. - Cognitive Market Research

Streamlined supply chains

With components sourced locally or regionally, manufacturers reduce lead times and transportation costs. This streamlined supply chain supports agile production's quick turnaround times.

Flexibility in Scaling Production

One of the hallmarks of agile manufacturing in Mexico is the ability to scale production up or down without significant disruptions. Whether demand spikes or drops, manufacturers can adjust seamlessly.

Integration of Advanced Technologies

From IoT-enabled production lines to AI-driven quality control, Mexican manufacturers embrace cutting-edge technologies. These tools enhance efficiency and enable real-time production process adjustments.

Conclusion

Agile manufacturing is no longer a luxury—it’s a necessity. And Mexico stands out as a prime location for businesses ready to embrace this model. With its strategic advantages and commitment to innovation, Mexico enables companies to meet dynamic demand with ease. Ready to future-proof your business? Mexico has the tools, talent, and technology to make it happen.

FAQs

1. What industries benefit most from Mexico Agile Manufacturing?

Industries like automotive, electronics, textiles, and consumer goods gain the most from Mexico’s agile manufacturing capabilities. These sectors often face fluctuating demand and require quick adaptation.

2. How does agile manufacturing reduce costs?

Agile manufacturing minimizes waste, optimizes supply chains, and speeds up production. These efficiencies lower overall costs, even for customized or low-volume orders.

3. Can small businesses take advantage of agile manufacturing in Mexico?

Absolutely! Mexico’s flexible manufacturing model is scalable, making it accessible for businesses of all sizes to compete effectively.

4. How does Mexico’s workforce support agile manufacturing?

Mexico’s workforce is skilled, adaptable, and experienced in modern production techniques. Their ability to quickly learn and implement new processes is essential for agility.

5. What role does technology play in Mexico’s agile manufacturing?

Technology is a cornerstone. From automation to data analytics, Mexican manufacturers use advanced tools to enhance flexibility and responsiveness in production.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about Reduce Manufacturing Costs with our curated collection of related blog posts.

- How Mexico Is Strengthening Supply Chains for Long-Term Stability

- 3 Hidden Costs You’re Avoiding by Manufacturing in Mexico (And Why It Matters)

- Mexico’s Customs Clearance: Why It’s Faster—and Smarter—for Manufacturers

- Setup Process for Manufacturing in Mexico: What You Should Know About Timelines, Permits, and Common Pitfalls

- The Most Overlooked Advantage of Mexico’s Logistics Infrastructure

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.