Last Updated on January 23, 2025

In the global manufacturing landscape, a growing number of companies are looking for the perfect location to optimize their operations. If you’re one of those businesses weighing options, here’s the thing: Mexico product assembly offers unmatched advantages in 2025. Let’s explore why this vibrant nation has become the premier choice for companies seeking to elevate their manufacturing game.

The Geography Advantage: Proximity Meets Opportunity

Picture this: Your assembly plant is just a stone’s throw away from your largest market. For companies in the United States and Canada, Mexico’s geographical location is a game-changer.

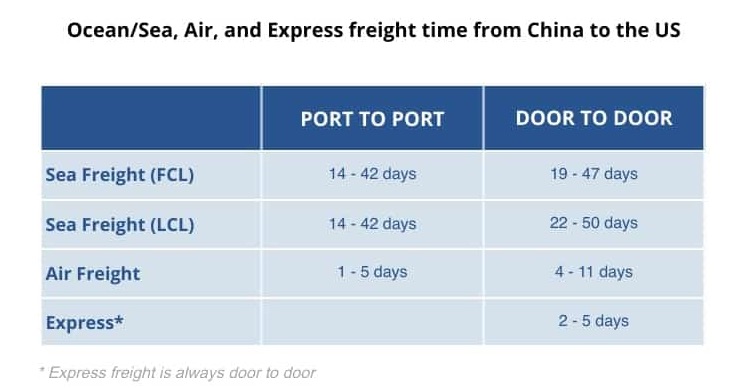

Shipping products from Asia takes weeks; from Mexico, it’s often a matter of days. This not only reduces lead times but also minimizes transportation costs. Plus, with the ever-evolving complexities in global supply chains, being close to home is no longer a luxury—it’s a necessity.

But it’s not just about proximity. Mexico’s strategic location gives companies access to Pacific and Atlantic trade routes, allowing for seamless distribution across the Americas, Europe, and Asia.

Skilled Workforce with Competitive Costs

Let’s talk talent. Mexico boasts a highly skilled and diverse workforce, especially in sectors like automotive, electronics, and aerospace. This is critical when you have a complex product to assembly. From seasoned engineers to diligent assembly line workers, the country’s labor pool is not only capable but also continuously growing in expertise thanks to partnerships between industries and technical training institutions.

Now, here’s the kicker: Labor costs in Mexico remain significantly lower than in the U.S. or Europe, but without compromising on quality. It’s a rare win-win situation where businesses benefit from cost savings while maintaining high production standards.

Infrastructure Built for Efficiency

Mexico’s infrastructure plays a pivotal role in enhancing its competitiveness as a manufacturing and product assembly hub, especially as we move into 2025, when supply chain resilience and efficiency will remain critical for businesses. The country’s extensive network of highways, railways, and ports is designed to support the rapid movement of goods, a key factor in reducing lead times and ensuring customer satisfaction in increasingly demanding markets.

Think about this: An assembly plant in Monterrey or Guadalajara can ship goods to Dallas or Los Angeles faster than many U.S. domestic manufacturers can. That’s the power of world-class infrastructure combined with proximity.

Highways and Logistics Efficiency

Mexico boasts one of the most developed highway networks in Latin America, connecting major manufacturing hubs like Monterrey, Guadalajara, and Mexico City with border cities and key ports. For product assembly plants, this means components and raw materials can be transported quickly from suppliers, and finished goods can reach distribution centers or export markets without delays. Efficient highways minimize disruptions, a factor that is especially important for industries with just-in-time manufacturing models.

Strategic Ports and Global Trade Connectivity

Mexico’s ports, such as Veracruz on the Gulf of Mexico and Lázaro Cárdenas on the Pacific, provide access to international shipping routes. These ports are equipped to handle large volumes of cargo, ensuring a steady inflow of imported materials and the smooth export of assembled goods. For manufacturers targeting North American, European, or Asian markets, this infrastructure is indispensable.

Railways Linking Key Regions

Mexico’s railway system plays a crucial role in connecting industrial zones to the U.S. and Canada. With the United States-Mexico-Canada Agreement (USMCA) reducing trade barriers, rail transport offers an efficient and cost-effective solution for moving heavy or bulk goods. For product assembly plants, rail access ensures seamless supply chain integration and supports high-volume production.

Investments in Modernization

In 2025, Mexico continues to make substantial investments in modernizing its transportation and communication systems. Initiatives such as smart highways, automated logistics hubs, and advanced port facilities underscore the country’s commitment to staying competitive in the global manufacturing landscape. These improvements future-proof Mexico’s infrastructure, enabling it to meet the evolving demands of industries like automotive, electronics, and aerospace.

5 Ways to Cut Costs with Assembly Services

- Consolidate suppliers—fewer vendors mean simpler logistics.

- Use local sourcing for non-critical components.

- Leverage Mexico’s duty-free programs like IMMEX.

- Optimize production scheduling to avoid overtime pay.

- Share facilities with a partner for reduced overhead.

Small adjustments can add up to big savings.

Conclusion: Don't Miss Out on Product Assembly Opportunities

Still on the fence about Mexico product assembly? Here’s a reality check: The longer you wait, the more opportunities you miss. With rising global competition and the ongoing demand for quicker, more cost-effective solutions, Mexico is the partner you need.

The benefits—proximity, skilled labor, cost-efficiency, robust infrastructure, and a pro-business environment—speak for themselves. Whether you’re relocating operations or just starting, Mexico offers the perfect springboard for growth.

So, what’s stopping you? It’s time to make the move.

FAQs on Why Mexico is the Best Choice for Product Assembly in 2025

1. What industries benefit the most from product assembly in Mexico?

Industries like automotive, electronics, aerospace, medical devices, and consumer goods thrive in Mexico due to its skilled workforce, advanced infrastructure, and favorable trade agreements.

2. How does Mexico’s workforce compare to other manufacturing hubs?

Mexico’s workforce is highly skilled, especially in technical fields. While labor costs are lower than in developed nations, the quality of work is on par with global standards.

3. Are there incentives for foreign companies to set up in Mexico?

Yes, programs like the maquiladora initiative offer tax benefits and duty-free imports for materials used in products destined for export, making Mexico an attractive choice.

4. What challenges should companies consider when setting up in Mexico?

While Mexico offers many advantages, companies should prepare for differences in regulatory processes and cultural practices. Partnering with local experts can help navigate these challenges effectively.

5. How does Mexico’s location impact supply chain efficiency?

Being close to the U.S. and Canada shortens lead times and reduces shipping costs. Mexico’s access to major trade routes also supports global distribution, enhancing supply chain efficiency.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about Assembly in Mexico with our curated collection of related blog posts.

- Car Brands Made in Mexico: A Look at Global Manufacturing Powerhouses

- Why Mexico is the Best Choice for Product Assembly in 2025

- Shifting Gears: Top 5 Automotive Manufacturing Trends in Mexico

- How Kitting Services in Mexico Streamline Your Manufacturing Operations

- The Auto Industry’s Production Advantage in Mexico: Analyzing the Factors Driving Mexico’s Success as a Global Automotive Manufacturing Hub

- Streamlining Your Operations: How Kitting Services Can Help You Compete in Mexico

- Why Mexico Is an ‘Undiscovered Opportunity’ for Entrepreneurs: The Focus on Mexican Manufacturing Companies

- Packaging Solutions in Mexico: Crafting Success in Every Box

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.