Last Updated on February 13, 2025

If you're considering setting up a manufacturing operation in Mexico, you've probably heard about the advantages of the border zone. But what makes it such a strategic choice? Is it just about proximity to the U.S., or is there more to the story Let’s break it down. Here are three key benefits that make Mexico’s Border Zone a smart move for manufacturers.

What is Mexico’s Border Zone and Why is it Critical for Manufacturing?

Overview of Mexico’s Border Zone

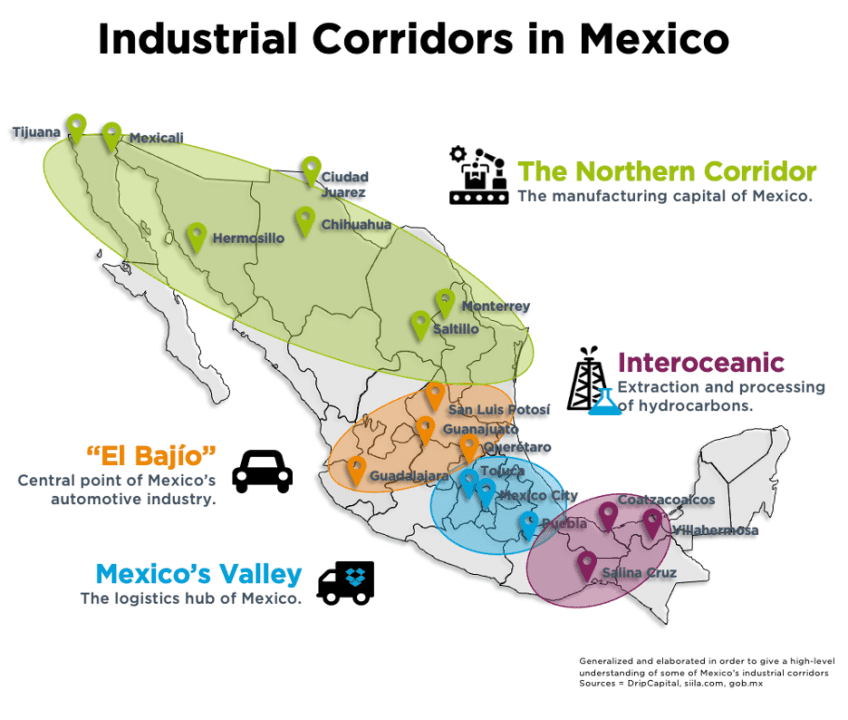

Mexico’s Border Zone refers to the region within approximately 20 to 30 kilometers (roughly 12 to 18 miles) of the U.S.-Mexico border. It includes major industrial cities like Tijuana, Mexicali, Ciudad Juárez, Reynosa, and Matamoros. This area has long been a manufacturing powerhouse, attracting companies from automotive, electronics, aerospace, and textiles.

One of the defining characteristics of the border zone is its integration into the U.S. economy. Many factories here operate under the IMMEX (Maquiladora) Program, which allows companies to import raw materials duty-free, provided they export the finished goods. This has made the border zone a prime location for international manufacturing operations.

1. Faster, Smoother Logistics: Get Your Products Moving

If supply chain efficiency is a top priority (and let’s be honest, when isn’t it?), Mexico’s Border Zone offers a huge advantage. Being right next to the U.S. border means faster shipping, fewer delays, and lower transportation costs.

Think about it—products manufactured in Tijuana, Juárez, or Matamoros can reach U.S. distribution centers within hours instead of weeks. Compare that to dealing with overseas supply chains, where delays at ports, customs bottlenecks, and long transit times can throw off production schedules.

- Shorter lead times: A truck from a factory in Mexico’s Border Zone can reach major U.S. cities in a day or two.

- Lower shipping costs: Less distance means less time spent on freight, fuel, and handling.

- Customs efficiency: Many border manufacturers operate under IMMEX (Maquiladora) programs, which streamline import/export processes.

And with nearshoring on the rise, companies that manufacture in the border zone gain a competitive edge by responding faster to market demands.

2. Lower Costs Without Sacrificing Quality

Labor and operational costs are always a major factor in site selection. One of the biggest reasons companies choose Mexico’s Border Zone is the significant cost savings—especially compared to the U.S. and other global manufacturing hubs.

- Competitive wages: While wages in Mexico are higher than in some offshore locations, they're still significantly lower than in the U.S., offering a great balance between affordability and skilled labor.

- Lower overhead: Rent, utilities, and other operating expenses are much cheaper in the border region.

- Government incentives: Programs like IMMEX and VAT exemptions reduce costs even further.

The most exciting part? These cost savings don’t compromise quality. Border factories produce goods for major global brands, ensuring high standards of production and quality control.

3. A Skilled and Ready Workforce

What use is a factory without skilled workers? One of the standout benefits of Mexico’s Border Zone is the deep pool of experienced labor. Decades of manufacturing investment have created a workforce that knows the industry inside and out.

- Trained in manufacturing: Many workers have experience in automotive, electronics, textiles, and other specialized industries.

- Bilingual and cross-border savvy: With daily business between Mexico and the U.S., many workers are bilingual and accustomed to international operations.

- Strong work ethic: Mexico is known for its dedicated and hardworking labor force, especially in manufacturing hubs near the border.

Plus, with universities and technical schools training the next generation of workers, companies can count on a steady stream of talent to keep operations running smoothly.

Mexico’s higher education system offers opportunities for U.S. community colleges to develop collaborative programs with technical universities in different regions in Mexico. Faced with rapid changes in global supply chains, the Mexican education system has adopted a stance of constant collaboration with regional economic sectors to understand industry needs and update curricula to prepare technicians and specialists in key productive areas. Mexico’s technical and technological system is one of the largest in the world. - International Trade Administration

Economic Zones: A Haven for Manufacturers

Mexico has established several Special Economic Zones (SEZs) to attract foreign investment and stimulate regional development. These zones offer additional incentives and benefits to manufacturers, making them highly attractive locations for operations.

These zones provide:

Skilled workforce: Proximity to technical schools and training programs.

Streamlined regulations: Simplified procedures for setting up and operating a business.

Infrastructure and utilities: Access to modern facilities, transportation networks, and essential services.

Yucatán Special Economic Zone

A hub for tourism, manufacturing, and logistics in southeastern Mexico.

Tijuana Industrial Park

A major manufacturing hub on the US-Mexico border.

Guadalajara Industrial Park

A significant center for technology and manufacturing companies.

Monterrey Industrial Park

A key location for manufacturing, logistics, and aerospace companies.

Final Thoughts: Manufacturing in Mexico’s Border Zone

Manufacturing in Mexico’s Border Zone isn’t just about proximity to the U.S.—it’s about efficiency, cost savings, and access to skilled labor. Whether you're relocating a factory or starting from scratch, this region offers a powerful combination of benefits that can give your business a competitive edge.

Looking for a faster supply chain, lower costs, and a talented workforce? Mexico’s Border Zone might be exactly what you need.

FAQs on Manufacturing in Mexico’s Border Zone

1. How does manufacturing in Mexico’s Border Zone compare to China?

Mexico offers shorter lead times, fewer supply chain disruptions, and easier communication with U.S. customers. While China may have lower labor costs in some regions, Mexico provides cost savings in logistics and tariff benefits under USMCA.

2. What industries benefit the most from manufacturing in Mexico’s Border Zone?

Automotive, electronics, medical devices, aerospace, and textiles are among the top industries leveraging the border zone’s advantages. The skilled labor force and logistics benefits make it a great fit for precision manufacturing.

3. Are there tax incentives for companies manufacturing in Mexico’s Border Zone?

Yes! Programs like IMMEX (Maquiladora) allow companies to import raw materials duty-free, provided the finished products are exported. There are also VAT exemptions and other incentives that reduce operational costs.

4. Is it difficult to find workers in Mexico’s Border Zone?

Not at all. The region has a well-established manufacturing workforce, and technical schools keep the talent pipeline strong. Many workers have years of experience in high-tech industries.

5. How secure is manufacturing in Mexico’s Border Zone?

Security varies by location, but many companies operate safely by investing in private security, secure industrial parks, and well-managed logistics strategies. The key is working with experienced partners who understand the region.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.