Last Updated on February 27, 2024

Two essential components are often at the center of electrical and electronic systems: wire harnesses and cable assemblies. At first glance, these two entities may seem similar, but they serve distinct purposes and have unique advantages. We examine the five critical differences between wire harnesses and cable assemblies in this comprehensive guide.

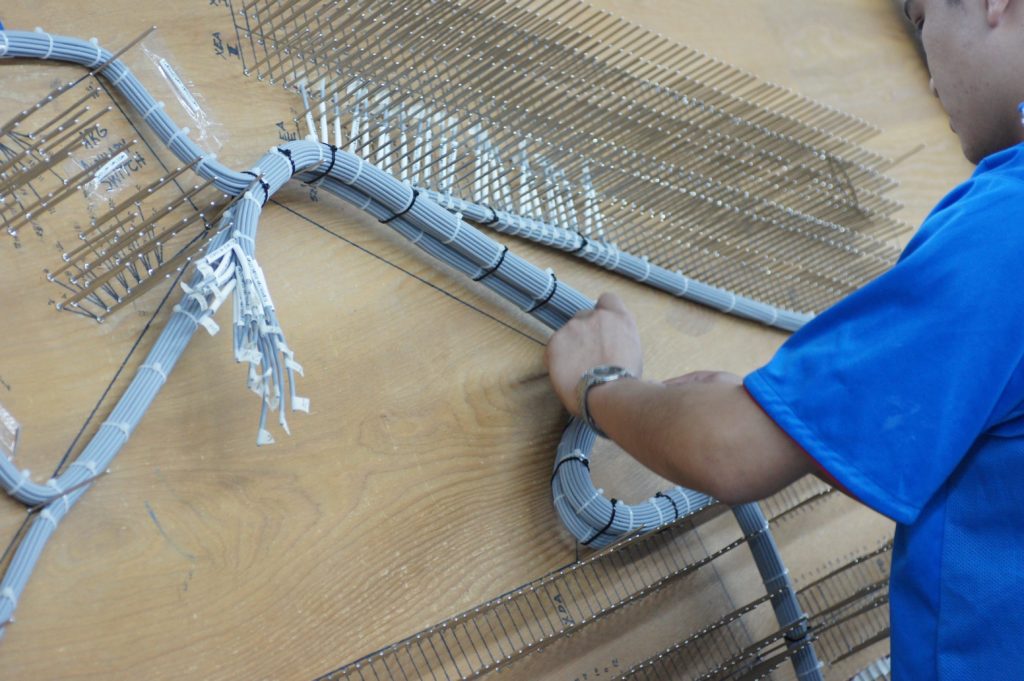

Wire Harnesses: A Closer Look

Definition and Function

Wire harnesses are meticulously organized bundles of wires, cables, and connectors. Its primary function is to transmit electrical signals and power efficiently between various components within an electrical system. Wire harnesses play a vital role in ensuring seamless operation of machinery, automotive systems, and a myriad of other applications.

Construction

Wire harnesses are characterized by their structured arrangement. They consist of multiple wires, typically color-coded for identification, bundled together and secured with various fasteners, such as zip ties, tape, or woven sleeves. This organized approach simplifies installation and maintenance, reducing wire damage or tangling.

Use Cases

Wire harnesses find extensive use in applications where precise routing and protection against environmental factors, such as heat, moisture, and abrasion, are critical. They are commonly employed in the automotive industry, aerospace, medical equipment, and industrial machinery.

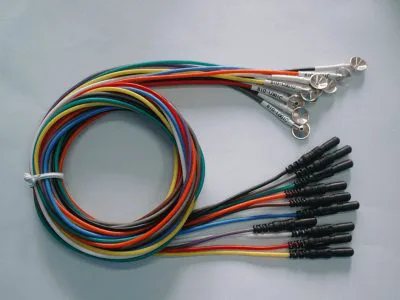

Cable Assemblies: A Detailed Examination

Definition and Function

Cable assemblies, on the other hand, are more versatile. It comprises cables, connectors, and often additional components like terminals or switches. Cable assemblies transmit data, signals, or power from one point to another while offering flexibility and adaptability.

Construction

Cable assemblies are inherently more flexible than wire harnesses due to their varied components. They are often custom-designed to suit specific applications, allowing for a broader range of cable types and connectors. This flexibility ensures compatibility with diverse systems.

A sample cable assembly. From Bisinfotech.

Use Cases

Cable assemblies are favored when adaptability and customization are paramount. They are frequently utilized in telecommunications, consumer electronics, and complex machinery, where component configuration may change frequently.

Key Differences

Now that we've examined wire harnesses and cable assemblies individually, let's highlight the five key distinctions between them:

1. Purpose

- Wire Harnesses: Primarily designed for power distribution and signal transmission within a fixed system.

- Cable Assemblies: Adaptable and versatile, suitable for various applications, including data transmission and dynamic systems.

2. Construction

- Wire Harnesses: Structured and organized, with fixed wire lengths and a focus on protection and organization.

- Cable Assemblies: Flexible, custom-built to meet specific requirements, with varying cable lengths and connectors.

3. Use Cases

- Wire Harnesses: Ideal for applications with a stable, unchanging configuration, requiring robust protection.

- Cable Assemblies: Suited for systems where changes in configuration or frequent connections and disconnections are common.

4. Complexity

- Wire Harnesses: Typically simpler in design, with fewer components.

- Cable Assemblies: More complex, accommodating a wider range of cables, connectors, and additional components.

5. Industry Applications

- Wire Harnesses: Predominantly used in industries like automotive, aerospace, and heavy machinery.

- Cable Assemblies: Widely applied in telecommunications, consumer electronics, and industries with evolving technology.

Conclusion

In summary, wire harnesses and cable assemblies serve as critical components in electrical and electronic systems, each with its distinct characteristics and advantages. Understanding the differences between them is crucial for selecting the right solution for your specific application. Whether it's the structural reliability of a wire harness or the adaptability of a cable assembly, making an informed choice ensures optimal performance and efficiency in your systems.

FAQs

1. What's the primary function of a wire harness?

- A wire harness organizes and bundles wires and connectors for efficient electrical signal transmission.

2. How do cable assemblies differ from wire harnesses in terms of complexity?

- Cable assemblies are more complex, incorporating additional elements like insulation, connectors, and shielding, suitable for intricate systems.

3. Where are wire harnesses commonly used?

- Wire harnesses find extensive use in industries like automotive, aerospace, and industrial machinery due to their durability and reliability.

4. What are the quality control challenges with cable assemblies?

- Cable assemblies demand more intricate testing methods, including insulation resistance, connector functionality, and shielding effectiveness.

5. Are cable assemblies more expensive than wire harnesses?

- Yes, cable assemblies tend to be pricier due to their added components and increased complexity, offering enhanced functionality at a higher cost.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.