Last Updated on May 2, 2024

Think of how your business could benefit from an efficient, cost-effective manufacturing operation. Almost too good to be true, isn't it? Mexico's modern factories are making this dream a reality for many businesses.

Mexico: A Manufacturing Powerhouse on the Rise

Gone are the days of Mexico being solely associated with low-cost labor. Today, the country boasts a network of state-of-the-art manufacturing facilities that are equipped with cutting-edge technology and staffed by a highly skilled workforce. This dynamic combination is revolutionizing the supply chain landscape, offering businesses a strategic advantage.

The Twin Pillars of Success: Cost-Effectiveness and Quality

So, what exactly makes Mexico's modern factories so successful? The answer lies in two key pillars: cost-effectiveness and quality. Here's how they work in tandem:

- Cost-Effectiveness: Mexico offers competitive labor rates compared to North American counterparts. This translates to significant savings on production costs, making it an attractive option for businesses looking to optimize their budgets.

- Quality: But Mexico isn't just about saving money. Modern factories prioritize quality. They invest heavily in advanced machinery and stringent quality control measures. The result? Products that meet international standards, ensuring customer satisfaction.

Beyond the Border: The Geographical Advantage

Factories and supply chains can benefit from Mexico's proximity to the United States and Canada. Mexico's strategic location acts as a catalyst for efficiency and responsiveness thanks to reduced shipping times, lower transportation costs, and a streamlined logistics process.

Transit times for finished goods are significantly reduced when manufacturing facilities are located closer to the major consumer markets such as the United States. By reducing lead times and improving customer satisfaction, products can reach customers faster.

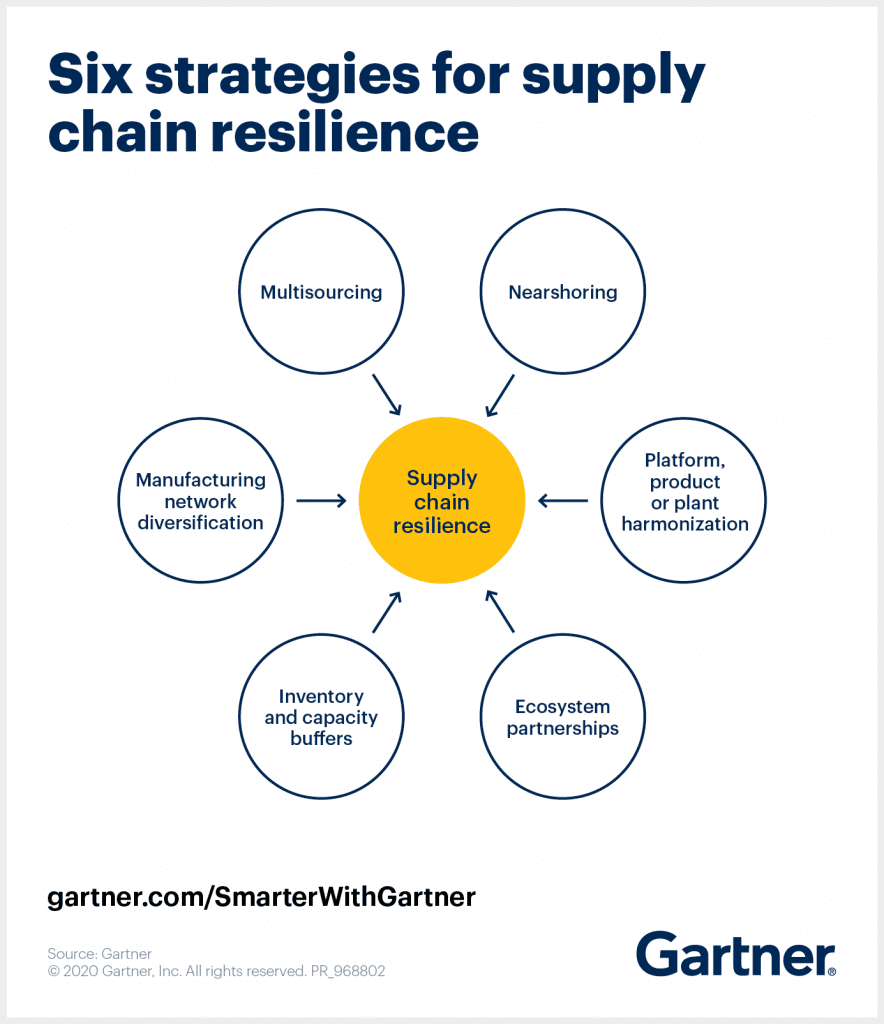

A recent trend among manufacturers is “nearshoring” — relocating overseas production facilities to countries closer to their markets. In the 1990s, many U.S. companies hopped on the offshoring trend to reduce costs; now, they are bringing some operations back to North America (specifically Mexico) to minimize the effects of supply chain disruptions while keeping costs in check.

Union Pacific

Furthermore, lower transportation costs translate directly into savings for businesses. Fuel consumption, transportation expenses, and logistics costs can be reduced by shipping goods over shorter distances. Cost-efficiency is particularly valuable in today's competitive business landscape, where companies are always trying to optimize their operations and maximize profits.

The benefits extend beyond immediate financial gains. By shortening the distance products travel, Mexico's modern factories contribute to a more sustainable supply chain. This translates to a lower carbon footprint, which is a growing concern for environmentally conscious businesses and consumers alike.

Conclusion: Look No Further Than Mexico's Modern Factories

Mexico's modern factories are no longer a hidden gem. They are a powerful force shaping the future of manufacturing. By offering a compelling combination of cost-effectiveness, quality, and geographical advantage, they are the key to unlocking supply chain success. So, if you're looking to streamline your operations, reduce costs, and build a more sustainable future for your business, look no further than Mexico's modern factories.

FAQs on Mexico's Modern Factories

1. Are there any cultural considerations when working with Mexican factories?

Absolutely. Understanding and respecting Mexican culture is key to building successful partnerships. Investing time in clear communication and fostering a collaborative environment goes a long way.

2. What industries are best suited for manufacturing in Mexico?

A wide range of industries can benefit from Mexico's modern factories. The automotive, aerospace, medical device, and electronics sectors are just a few examples.

3. How can I ensure the quality of products manufactured in Mexico?

Many Mexican factories adhere to strict international quality standards. However, conducting on-site inspections and establishing clear quality control protocols can provide additional peace of mind.

4. What are the logistics considerations for manufacturing in Mexico?

Mexico boasts a well-developed infrastructure, making transportation efficient. Partnering with a reputable logistics provider can further streamline the process.

5. How can I find the right factory partner in Mexico?

Conduct thorough research and consider attending industry trade shows in Mexico. There are also reputable sourcing companies that can help you find the perfect match for your needs.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about Mexico Manufacturing Facilities with our curated collection of related blog posts.

- Why Mexico Isn’t a Perfect Manufacturing Solution (and What That Really Means)

- Can Moving Manufacturing to Mexico Really Be Turnkey? Here’s What You Need to Know

- Setup Process for Manufacturing in Mexico: What You Should Know About Timelines, Permits, and Common Pitfalls

- Americans Say They Want More U.S. Factory Jobs—So Why Don’t They Want to Work in Them?

- Top 10 Well-Known American Companies in Mexico—Should You Be Next?

- Why Factories in Mexico Are the Preferred Choice for Nearshoring

- 5 Easy Steps to Move Your Production to a Mexican Factory

- 3 Key Benefits of Operating in Mexico’s Border Zone