Last Updated on February 26, 2024

Globalization has increased the number of options available to businesses when it comes to outsourcing manufacturing of their products. Depending on the company's priorities and needs, companies can choose between nearshore, offshore, and onshore manufacturing. A company seeking to make an informed decision about their outsourcing manufacturing strategy must understand the differences between each of these manufacturing methods.

Outsourcing Manufacturing Options: Nearshore Manufacturing, Offshore. What's the Difference? Share on XThroughout this blog post, we will examine the differences between nearshore, offshore, and onshore manufacturing and help you decide which outsourcing manufacturing options, including the decision to move manufacturing to Mexico, are most suitable for your company.

Nearshore Manufacturing

Nearshore refers to outsourcing manufacturing to a company situated in a nearby country. A US company may, for example, outsource work to a company in Mexico. In this type of outsourcing, lower labor costs are achieved while maintaining similar time zones and cultural compatibility.

Advantages of Outsourcing Manufacturing to Nearshore:

The benefits of outsourcing manufacturing to a nearshore partner in Mexico, aside from the obvious advantage of having your operations close to your business headquarters, are great:

- Economical Labor: Nearshore manufacturing allows companies to take advantage of lower labor and operating costs in nearby countries such as Mexico without having to incur the additional expenses associated with offshore manufacturing. You have access to an affordable, and often plentiful labor force in Mexico, such as the Maquiladora.

- Cultural Compatibility: A company that outsources to a nearby country may share a similar culture and language, which can help facilitate communication and understanding between the two organizations.

This is especially true for shelter companies in Mexico that border Texas and California; Mexico, Texas and California share many common cultural experiences and traditions with the Latino community, as well as the English and Spanish language, of which both sides are commonly fluent. - Speed of Execution: Nearshore manufacturing means that the manufacturing facility is located in a nearby country, which can help reduce transportation costs and lead times. It also allows for more frequent visits to the manufacturing facility for quality control and other purposes. Consulting firm Accenture recently purchased a Nearshore firm for this very reason:

For today’s CMO, it’s all about greater speed to market, responsiveness and relevancy, said Brian Whipple, global managing director of Accenture Interactive.

Despite the numerous benefits of nearshore manufacturing, there are a few drawbacks as well. Nearshore manufacturing may not always provide the cost savings that businesses expect. In some cases, labor costs may differ between countries geographically close to the home country and those geographically further away, affecting the cost-effectiveness of nearshoring.

Offshore Manufacturing

Offshore refers to outsourcing work to a company located in a different country, often one that is geographically far away unlike a shelter company in Mexico.

A US company may outsource work to a company located across the ocean, usually in central Asia (such as China) or in southern Asia, for example, India or Bangladesh.

Advantages of Outsourcing Manufacturing to Offshore

Outsourcing manufacturing to another country has the following benefits:

- Lower Labor Costs: Some businesses can benefit from offshore manufacturing by taking advantage of lower labor costs in countries where wages are lower than in their home country, which can result in significant cost reductions.

- Operational Cost Savings: Aside from reducing overhead costs such as rent, utilities, and administrative expenses, offshore manufacturing can also reduce other operational costs such as infrastructure, raw materials, and regulatory compliance.

- Raw Material Costs: Offshore manufacturing locations may have access to cheaper raw materials or alternative sources of supply, which can help businesses reduce their procurement costs.

Because of the large cultural and language differences with many Offshore partners, the need to have collaboration between your company and your Offshore partner can be difficult. According to Chron, this creates a hurdle for collaboration between home offices and their offshore partners:

The many U.S. and global dialects of English can create "What'd you say?" moments between people who -- in theory -- should understand one another. Accents can make English speakers from different parts of the world strain to decipher each other's speech. More confoundingly, non-native speakers may slip into the sentence structure of their native language. Without an understanding of the colloquial speech and slang that can dominate exchanges between colleagues, misunderstandings can occur.

Onshore Manufacturing

An onshore operation is one in which all business operations are carried out within the same country. As a result, the company does not outsource any work overseas or to countries nearby. When there is a preference to keep jobs in the country or outsourcing is not financially feasible, this business model may be used.

Advantages of Outsourcing Manufacturing to Onshore

This approach has several obvious advantages and challenges:

- Quality Control: Businesses can maintain greater control over the manufacturing process by manufacturing on-site, ensuring consistent quality standards and the reliability of their products.istics for moving your product to market are reduced.

- Intellectual Property Protection: Onshore manufacturing can provide greater intellectual property protection, as businesses can rely on stronger legal frameworks and regulatory systems to protect their proprietary technology and trade secrets.

- Reduced Transportation Costs: Depending on your Onshore partner's proximity to your company, your time-to-market may also be reduced. If your partner is across the country from you, your freight and shipping costs may be as much (or more) than using a Nearshore option.

Despite several benefits associated with this approach, including reduced shipping costs and improved quality control, higher wages and more stringent labor laws may result in higher labor costs. Living standards and costs of living in developed countries are generally higher, resulting in higher wages for workers. In addition, manufacturers are forced to increase labor costs as a result of stricter labor laws and regulations, such as the provision of health insurance and retirement benefits to their employees.

Conclusion: Weighing the Benefits of Your Outsourcing Manufacturing Options

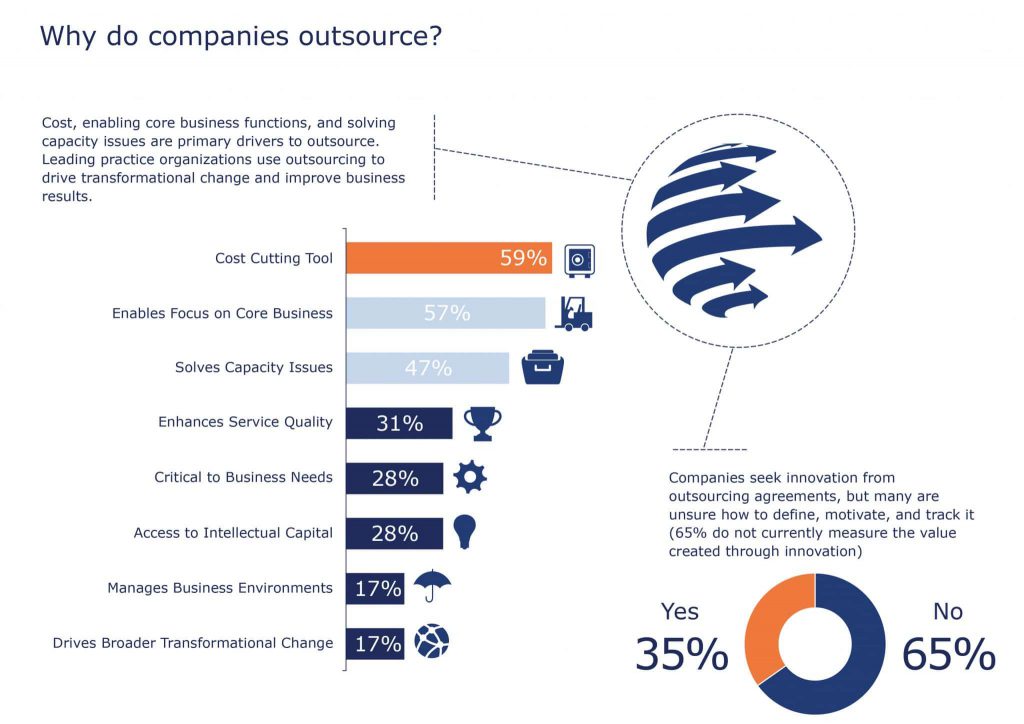

There are two main factors that determine the benefits of outsourcing: execution and cost. Despite the importance of factors such as language and labor skill, they are not nearly as important as the ability to reduce the cost of your product (through labor or production) and the ability to get your product to the market in the most efficient manner.

In considering outsourcing manufacturing options, a business may take into account the needs and goals of the business and the product they are producing, but cost-savings are often the most important consideration.

There are two main factors that determine the benefits of outsourcing: execution and cost. Share on XFAQs about Nearshore, Offshore, and Onshore Outsourcing

Q1: What is the difference between nearshore, offshore, and onshore outsourcing?

A1: Nearshore outsourcing refers to contracting services from a neighboring country, typically within a similar time zone. Offshore outsourcing involves partnering with a company located in a different geographical region, often with significant time zone differences. Onshore outsourcing, on the other hand, entails hiring a service provider within the same country as the client's operations.

Q2: What are the advantages of nearshore outsourcing?

A2: Nearshore outsourcing offers several benefits, such as improved communication due to overlapping time zones and cultural similarities. It can lead to better collaboration, reduced language barriers, and easier travel arrangements, allowing for frequent face-to-face meetings when necessary. Additionally, nearshore outsourcing often results in lower costs compared to onshore alternatives.

Q3: Why would a company choose offshore outsourcing?

A3: Offshore outsourcing provides access to a global talent pool and can significantly reduce labor costs. Companies may choose offshore outsourcing when they require specialized skills that are not readily available or are expensive in their home country. It allows organizations to leverage cost-effective resources while maintaining flexibility in scaling their operations.

Q4: Are there any challenges associated with offshore outsourcing?

A4: Offshore outsourcing can present certain challenges, such as language barriers, cultural differences, and the potential for miscommunication due to time zone disparities. Managing remote teams across different countries and coordinating project timelines may require additional effort. However, these outsourcing manufacturing options and their challenges can be mitigated by choosing experienced outsourcing partners and implementing effective communication and project management strategies.

Q5: When should a company consider onshore outsourcing?

A5: Onshore outsourcing is particularly suitable when a company prioritizes proximity, easy collaboration, and stringent control over operations. It may be preferred in situations where face-to-face interactions, regulatory compliance, and intellectual property protection are crucial. Onshore outsourcing can also be beneficial for industries that require specific local knowledge or when dealing with sensitive information that demands a higher level of security.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.