Last Updated on August 30, 2023

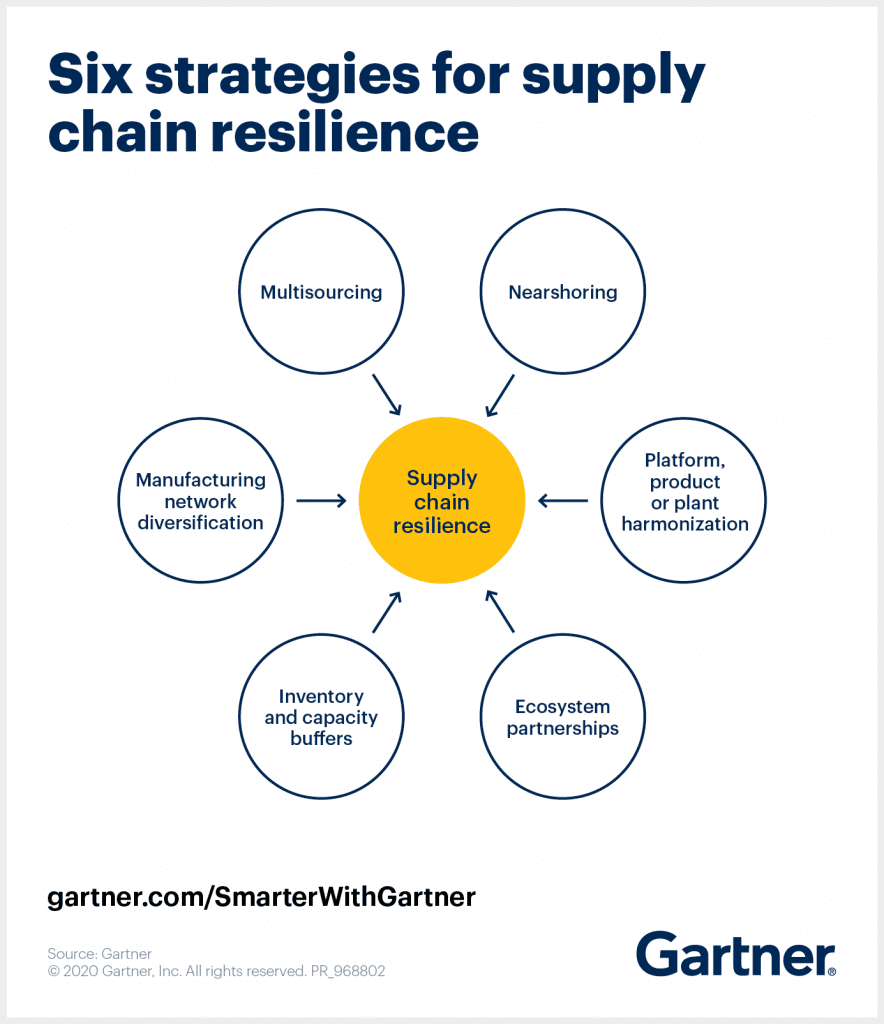

In an increasingly interconnected global economy, supply chain management has become a critical aspect of business success. The COVID-19 pandemic highlighted the vulnerabilities of complex, far-reaching supply chains, prompting companies to explore more resilient alternatives. Nearshoring has emerged as a strategic solution, offering businesses a way to mitigate supply chain risks while capitalizing on geographical proximity. In this comprehensive guide, we will delve into the concept of nearshoring, its benefits, challenges, and how it can effectively address supply chain vulnerabilities.

What is Nearshoring?

Nearshoring involves relocating a company's manufacturing or service operations to a nearby country, often with shared borders or geographical proximity. This approach offers advantages such as reduced transit times, improved communication, and increased control over the supply chain. Unlike offshoring, which involves moving operations to distant countries with lower labor costs, nearshoring focuses on maintaining logistical and cultural proximity.

What makes nearshoring different from offshoring is that the provision of manufacturing services is executed by companies whose location is close to that of the contracting company. It is generally sought that the two companies that enter into such a relationship share borders. In simple terms, nearshoring is outsourcing production processes whose activities fall on a company close to the client company. If locating manufacturing far from the home country of the client company amplifies supply chain risk, then locating production to home reduces supply chain risks.

In recent years, the most common offshoring practice has been hiring companies in China.

The Benefits of Nearshoring

- Reduced Supply Chain Complexity and Risk Embracing nearshoring simplifies supply chain complexity by shortening distances between suppliers, manufacturers, and consumers. This minimizes disruptions caused by geopolitical events, natural disasters, or transportation delays.

- Enhanced Responsiveness Nearshoring fosters quicker response times to market changes and customer demands. With reduced lead times, companies can adapt to shifts in demand and design alterations more effectively.

- Cultural Affinity Proximity often implies shared cultural and linguistic characteristics, leading to smoother collaborations and fewer misunderstandings. Cultural alignment can also lead to improved customer service and stronger relationships.

Challenges to Consider

- Labor Cost Variations While nearshoring might not offer the same cost advantages as offshoring, the benefits of reduced risk and better quality control can often outweigh the difference in labor costs.

- Infrastructure and Technological Maturity Some nearshore destinations might have less developed infrastructure or technological capabilities. Research and investment are crucial to ensure seamless operations.

- Talent Availability Companies must assess the availability of skilled labor in potential nearshore locations. A sufficient talent pool is essential to maintain production quality and efficiency.

The Transition From Offshoring to Nearshoring

The benefits of moving manufacturing to a low-cost strategic location, even though it was located on the other side of the world, represented great savings opportunities for many companies. Initial conditions prevalent in the countries where they were manufactured made this the case for this mode of doing business. However, this situation has proven challenging to sustain in the long run.

The cost of labor in China, and other geographically distant low-cost locations, has risen appreciably in recent years. In addition, such countries typically have a weak legal and regulatory infrastructure. This being the case, security and intellectual property risks have been bothersome and common problems for entrepreneurs. Adding to these factors’ appreciable differences in time, culture, and language exist. In the end, what once seemed profitable has proven not to be the best option for low-cost manufacturing and mitigating supply chain risks.

The Tipping Point for Nearshoring and More Secure Supply Chains

The COVID-19 pandemic exposed American supply chains' fragility and enormous dependence on Chinese suppliers. To reduce the United States' reliance on Asian suppliers, many companies have moved factories to strategic locations. This is a better, safer, and more cost-effective alternative. The leading country of choice when considering these variables is Mexico.

National security requires the United States to generate more economic development, jobs, and growth in the Americas. This is to secure supply chains and positively affect migratory patterns. Over time, relocating manufacturing supply chains has become increasingly important. For example, the pandemic affected industries by lack of access to critical components. With distant supply chain components partially paralyzed due to the Covid crisis, industrial production was curtailed by a tight supply of inputs for manufacturing, most of which originated in China. As this situation could not stand, manufacturers began closely examining and executing the process of moving production closer to home.

Because of this, the nearshoring trend will continue to be the most effective option for businesses in the short and medium term. In the case of countries such as Mexico, this will represent an excellent opportunity to further their economic progress. In addition, moving manufacturing from China to Mexico reduces supply chain risks.

At the same time, governments are expanding incentive programs encouraging local manufacturing for several priority industries in North America, for reasons including national security, competitiveness, and self-sufficiency. In the United States, communication technologies and space technologies and systems are now considered relevant for national security, while Canada supports aerospace, medical technology, and next-generation technology. Meanwhile, Mexico has sectoral promotion programs that allow for preferential tariffs on inputs for manufacturing. Self-sufficiency has likewise increased in importance, with Canada expanding support for domestic production of pharmaceuticals and medical devices.

To regionalize or not? Optimizing North American supply chains

Shortening the Supply Chain Is an Economic Development Opportunity for Mexico

Due to the influence of the nearshoring trend of tightening supply chains, Mexico has benefited significantly from the arrival of many companies to its shores. This is thanks to its proximity as a strategic location to ensure timely and regular supply and to the benefits that accompany the free trade treaty between the United States, Mexico, and Canada (USMCA).

Strategies for Successful Nearshoring

- Comprehensive Market Research Thoroughly evaluate potential nearshore locations by considering factors like labor force expertise, transportation networks, political stability, and economic incentives.

- Supply Chain Mapping Map your supply chain to identify critical components and potential risks. This assessment guides the selection of nearshoring partners and locations.

- Collaborative Partnerships Forge partnerships with local suppliers, manufacturers, and service providers. These collaborations enhance understanding and responsiveness within the supply chain.

Conclusion: Supply Chain Risks Can Be Balanced Through Nearshoring

Nearshoring offers a balanced approach to supply chain management, providing proximity advantages without sacrificing cost-effectiveness. By strategically relocating operations to nearby countries, businesses can navigate supply chain risks more adeptly and maintain agility in responding to market dynamics. As the global landscape evolves, nearshoring stands as a viable solution for building resilient supply chains.

FAQs about Nearshoring and Supply Chain Risks

1. What is the difference between nearshoring and offshoring? Nearshoring involves relocating operations to nearby countries, often with shared borders, to maintain logistical and cultural proximity. Offshoring, on the other hand, moves operations to more distant countries, often for cost-saving reasons.

2. Can nearshoring completely eliminate supply chain risks? While nearshoring reduces certain risks related to distance and geopolitical events, it cannot eliminate all supply chain risks. However, it enhances a company's ability to manage and respond to disruptions.

3. What are some industries that can benefit from nearshoring? Industries with complex and time-sensitive supply chains, such as electronics, automotive, and pharmaceuticals, can benefit significantly from nearshoring.

4. How do I choose the right nearshoring location? Choosing the right nearshoring location involves evaluating factors like labor expertise, infrastructure, political stability, and market accessibility. Comprehensive research and supply chain mapping are essential.

5. Is nearshoring suitable for all businesses? Nearshoring is particularly beneficial for businesses with intricate supply chains and a need for quick response times. However, its suitability depends on the specific requirements and objectives of each company.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.