Last Updated on September 13, 2023

The trend of reshoring is on the rise. With concerns about the high cost of labor in China and the difficulties of managing a complex global supply chain, many companies are choosing to relocate their operations closer to home. Companies are concerned about the impact of reshoring on supply chain management and logistics.

While reshoring offers many benefits, such as increased control over the production process and shorter lead times, it also presents new challenges for supply chain management and logistics. In this blog post, we will explore the impact of reshoring on these critical functions and discuss the challenges and solutions for effective supply chain management and logistics in a re-shored environment.

The Definition of Reshoring

Reshoring is the process of bringing back manufacturing operations that were previously outsourced to other countries, typically back to the company's home country. It is a trend driven by factors such as rising labor costs in outsourcing countries, concerns about supply chain disruptions and quality control, and the desire to bring production closer to customers and end-users. The goal of reshoring is to improve overall efficiency and competitiveness, reduce costs, and increase the control and flexibility of the production process.

Background on the Trend of Reshoring From China to Mexico

The trend of reshoring from China to Mexico has gained attention in recent years as companies seek to reconfigure their global supply chains for various reasons. This trend represents a shift in manufacturing and production operations from China, which has long been a dominant player in global manufacturing, to Mexico, a neighboring country with its own set of advantages for businesses.

Mexico has also made significant investments in its manufacturing sector and has developed a strong pool of skilled workers, which has made it an attractive destination for reshored manufacturing operations. Share on XMexico offers a number of advantages as a manufacturing location, including lower labor costs, improved transportation infrastructure, and proximity to the United States, which is the largest consumer market in the world. Mexico has also made significant investments in its manufacturing sector and has developed a strong pool of skilled workers, which has made it an attractive destination for reshored manufacturing operations. The combination of these factors has helped to drive the trend of reshoring from China to Mexico, and has positioned Mexico as a major player in the global manufacturing industry."

Association for Supply Chain Management

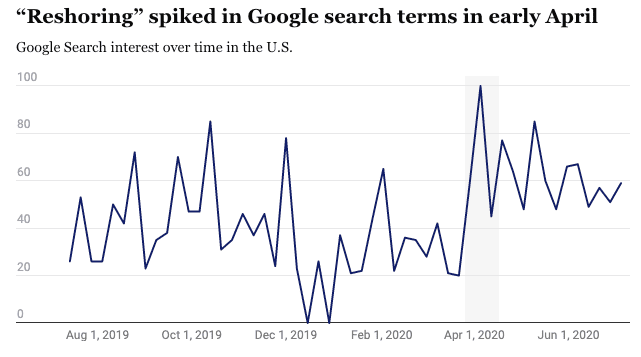

According to China Briefing, "The concept of “reshoring” took off in China after the instigation of the China-US trade war in 2018, when tariffs on billions of dollars’ worth of Chinese goods led some investors to reconsider the viability of China as a destination for manufacturing and other operations."

"Given the competitive nature of Mexico as an option, the ongoing investment by the United States in manufacturing capabilities, and the supply chain disasters hitting industry on an almost daily basis, the question must be asked: If your company is not reshoring, why not? Price competition is closer than ever and limiting disruption is more important than ever to prevent lost sales up and down the supply chain. Moreover, political will exists to provide additional local incentives."

https://www.foley.com/en/insights/publications/2022/05/is-mexico-winning-reshoring

Supply Chain and Logistics: The Impact of Reshoring

The impact of reshoring on supply chain management and logistics can be both positive and negative.

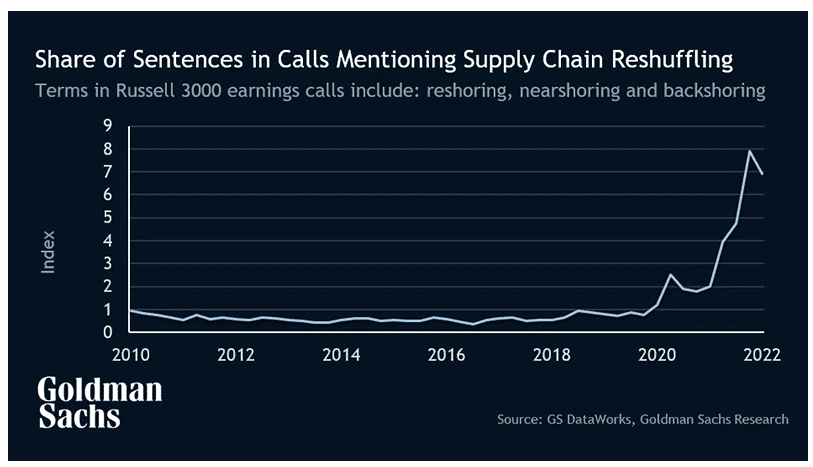

"Supply chain leaders are considering several courses of action in light of this reality. Some are expanding and diversifying production and manufacturing in hopes of minimizing their dependence on a small number of overseas suppliers. Others are relocating production and manufacturing operations to other parts of the world based on what transpired over the past two years. A third strategy that is gaining momentum is reshoring – companies are scaling down their geographic production and manufacturing footprints and bringing more activity back to within their borders.

Manufacturing Net

Reshoring is primarily intended to regain end-to-end supply chain control. Companies are taking back some of what they’ve outsourced for decades in hopes of mitigating risk that is outside of their control.

Reshoring is primarily intended to regain end-to-end supply chain control. Companies are taking back some of what they’ve outsourced for decades in hopes of mitigating risk that is outside of their control. Share on XGlobal Supply Chain Management Is Undergoing a Strategic Shift as a Result of Reshoring From China to Mexico

It's important to note that the decision to reshore manufacturing from China to Mexico is not without its challenges. Companies must assess factors such as supply chain infrastructure, regulatory compliance, political stability, and the availability of local suppliers before making this transition. Additionally, the choice to reshore varies by industry, with certain sectors benefiting more from the Mexico option than others.

Overall, the trend of reshoring from China to Mexico reflects a strategic shift in global supply chain management, driven by factors like cost considerations, proximity to markets, trade agreements, and the need for increased supply chain resilience. It's a trend that continues to evolve as companies adapt to changing market dynamics and geopolitical factors.

Benefits of Reshoring for Supply Chain and Logistics

Reshoring can offer several benefits for supply chain and logistics. Here are some of the potential benefits:

Shortening of Lead Times: According to Marketplace: "“It used to take 21 days for merchandise from China to come to the port of LA or port of Long Beach and get to our warehouses. Today, it takes 159 days,” said Isaac Larian, CEO of MGA Entertainment, which makes Little Tikes toys like Cozy Coupes — those red and yellow plastic cars with googly eyes that kids ride in. It has factories around the world, including in Hudson, Ohio."

Improved Inventory Management: Shorter supply chains allow for more precise inventory management. Companies can implement just-in-time (JIT) inventory practices, reducing the need for large warehouses and excess inventory. This leads to cost savings and frees up capital that would otherwise be tied up in inventory.

Improved Control Over the Production Process: Reshoring can provide companies with greater control over their production processes, including quality control, production scheduling, and inventory management. This can lead to increased efficiency and competitiveness. "With more control over the supply chain and a greater ability to oversee the manufacturing process, reshoring makes it possible to reduce cost gaps. This opportunity enables manufacturers to more accurately make predictions and control their budgets." - Universal Polymer & Rubber Ltd., Inc.

Increased Flexibility in Responding to Market Changes and Customer Demand: As a manufacturer of garments, Turtle Fur needed to scale up and reduce its labor pool for seasonal production (an increase or decrease of 20% in workforce depending on the season). Maintaining a large labor force all year round was not profitable. As a result of reshoring their manufacturing operations to Mexico, Turtle Fur was able to meet seasonal and product demands without compromising the reliability of their supply chain.

Improved Quality Control: Proximity to production facilities enables better oversight of quality control processes. Companies can maintain stricter quality standards, reducing the likelihood of defective products reaching customers. This results in higher customer satisfaction and fewer returns.

Reduced Transportation Costs: By bringing production closer to customers, reshoring can reduce transportation costs and lead to improved delivery times. When production is closer to the market, companies can use more cost-effective transportation modes, such as ground shipping, instead of relying on expensive air or sea freight. This cost reduction positively impacts the bottom line.

The reshoring of manufacturing’s most direct impact on supply chain strength is shortening transit times. In these strategies, manufacturers become physically closer to their downstream supply chain partners, making them less prone to disruption and more likely to withstand unexpected delays.

Can Reshoring Manufacturing Spark a New Era of Resilience in Supply Chains?

Environmental Benefits: Shorter supply chains reduce carbon emissions associated with long-distance transportation. Reshoring can align with sustainability goals, making it more appealing to environmentally conscious consumers and regulators.

"Inter Parfums, the New York-based global manufacturer of perfumes and cosmetics, has recently made a resolve to leave China. When Shanghai went into a lockdown two months ago, millions of dollars’ worth of designer perfumes and cologne stocked in warehouses became inaccessible. As a result, Inter Parfums lost significant sales during the period.

https://maritime-executive.com/article/reshoring-can-reduce-freight-costs-but-it-may-prove-difficult

“How good is it to have cheaper components when you cannot get them? For a consumer products company like us, you need to have super stability in supply,” Jean Madar, founder and chairman of Inter Parfums, told The Wall Street Journal."

Challenges and Solutions for Effective Supply Chain Management and Logistics in Reshoring

In addition to the challenges of reshoring production and manufacturing operations back to their home countries, there are also several solutions available to deal with the challenges of managing supply chains and logistics effectively.

Integrating New Suppliers Into the Supply Chain: The process of reshoring may involve working with new suppliers, which may require significant investment in new relationships and processes.

"You need to establish a supply chain and ensure that you have all the parts and materials required for your products in the country where they are made. This takes time because it is difficult to find reliable suppliers who will give you good quality at reasonable prices. It is also difficult for them to understand what exactly you need and how they should supply much of each material."

Benjamin Wann

Managing Cultural Differences: Reshored companies may have to navigate cultural differences between their home country and the reshored location, which may impact communication and collaboration.

"When moving operations to a different country, cultural and language barriers are very common. If companies are unable to manage these barriers effectively, it can prove fatal to their nearshoring efforts.

Although citizens of the USA and Mexico are better positioned to understand each other, it is best to take help from cultural mediators to avoid conflict.

Companies need to have reliable and qualified partners who can understand the company culture and the local culture. This helps bridge the cultural and language gap between the local employees and the company. "

https://www.timedoctor.com/blog/nearshoring-to-mexico/#challenges

Overcoming Infrastructure and Technology Constraints: In addition to infrastructure and technology challenges, offshore operations may face challenges related to new equipment, processes, and training, as well as access to reliable transportation and communication networks. The Brooking Institute writes:

Improved tracking and tracing would help identify logjams and allow firms to take action that eases delivery problems. Right now, it is not always easy to keep track of the hundreds of thousands of shipping containers that traverse the world. Using technology to monitor movements and anticipate logjams would go a long way to addressing logistical problems and easing transportation logjams.

Brooking Institute

Conclusion: Reshoring Presents Both Opportunities and Challenges for Supply Chain Management and Logistics

In conclusion, reshoring presents both opportunities and challenges for supply chain management and logistics. While it can provide significant benefits in terms of reduced lead times, improved quality control, and increased flexibility, it can also require significant investments in new relationships, infrastructure, and technology.

To be successful in a reshored environment, companies must carefully evaluate the costs and benefits of reshoring. They must develop effective strategies for managing suppliers and logistics, and be prepared to navigate the challenges that arise along the way. By doing so, they can position themselves for long-term success in a rapidly changing global market.

FAQs on The Impact of Reshoring on Supply Chain Management and Logistics

1. What is reshoring, and how does it impact supply chain management and logistics?

Reshoring refers to the practice of bringing manufacturing or production operations back to the home country from offshore locations. The impact on supply chain management and logistics is significant, as it can lead to shorter supply chains, reduced lead times, and greater control over production processes. However, it may also entail higher costs initially.

2. What are the main drivers behind the reshoring trend in supply chain management?

Several factors drive the reshoring trend, including rising labor costs in offshore locations, the need for improved quality control, geopolitical risks, and the desire for more sustainable and resilient supply chains. The COVID-19 pandemic also highlighted vulnerabilities in global supply chains, prompting companies to reconsider their strategies.

3. How can reshoring affect the overall cost structure of supply chain management and logistics?

While reshoring may increase production costs due to higher labor and operational expenses in the home country, it can lead to cost savings in other areas. Shorter supply chains can reduce transportation and inventory costs, and improved quality control can minimize expenses related to defects and recalls. The net impact on costs depends on various factors, including the industry and specific circumstances of each company.

4. What challenges might organizations face when implementing reshoring in their supply chain management strategies?

Organizations may encounter challenges such as finding skilled labor, investing in updated technology and automation, navigating regulatory changes, and managing the transition period. Additionally, the initial investment required to establish or expand domestic production facilities can be a barrier for some companies.

5. How can companies effectively balance reshoring with maintaining a global supply chain presence?

Balancing reshoring with a global supply chain presence involves strategic planning. Many companies adopt a hybrid approach by reshoring critical or high-value components while maintaining offshore suppliers for less critical parts. This allows them to mitigate risks and leverage the advantages of both domestic and international sourcing. Effective communication and collaboration with suppliers and partners are essential for achieving this balance successfully.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.