Last Updated on July 17, 2024

Mexico has established itself as a top destination for businesses looking to source materials for their manufacturing processes. With a range of advantages, including a well-established manufacturing industry, favorable trade agreements, and competitive costs, there are many benefits to materials sourcing for manufacturing in Mexico.

The Advantages of a Localized Approach

Traditionally, companies source materials overseas, often from distant locations like Asia. However, this approach comes with drawbacks. Shipping times can disrupt production schedules, and import duties can add unexpected costs. This is where nearshore manufacturing and a Mexican partner like NovaLink come into play.

Competitive Costs

One of the main advantages of materials sourcing for manufacturing in Mexico is the competitive costs. Mexico has a lower cost of labor compared to many other countries, making it an attractive location for businesses looking to reduce their production costs. Additionally, the Mexican government offers tax incentives and other benefits to foreign investors, which further reduces the cost of doing business in the country.

Shipping rates are also a cost concern: Forecasts warn that ocean cargo prices could reach $20,000 - even reach the Covid era high of $30,000 - and stay there through 2025 as freight rates rise.

Proximity to the United States

The proximity of Mexico to the United States is a significant advantage for materials sourcing for manufacturing in Mexico. The close proximity allows for faster and more efficient transportation of goods, reducing lead times and increasing the speed of production. Manufacturers sourcing materials in Mexico can benefit from the lower labor and production costs in Mexico while still being able to access the vast market opportunities in the United States.

The close geographical location also helps in reducing transportation costs, as goods can be transported by land, air, or sea with ease. This allows companies to remain competitive in the global market and provide high-quality products at lower prices. According to the ESG Blog:

Nearshoring can reduce the cost of production, as labor and materials are typically cheaper in nearshore locations than in other international markets. Reduced transportation costs – Nearshoring also cuts transportation costs, since goods can be shipped more quickly and easily to their destination.

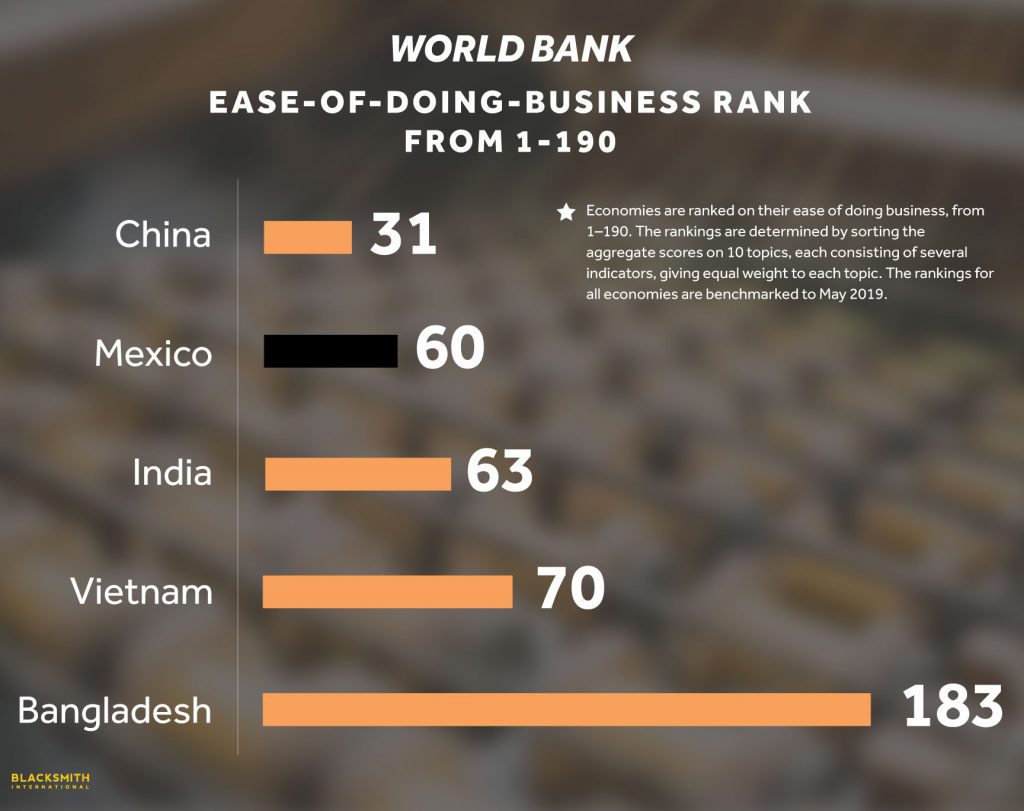

Source: Blacksmith International

Favorable Trade Agreements

Mexico has established several favorable trade agreements, including the United States-Mexico-Canada Agreement (USMCA), the European Union-Mexico Free Trade Agreement, and more. These agreements allow companies to facilitate trade between Mexico and its North American neighbors by reducing trade barriers, eliminating tariffs, and facilitating the import and export of goods. As a result, businesses can source materials from Mexico without facing high import taxes, which can significantly reduce the overall costs of production.

Growing Manufacturing Sector and Government Support

The manufacturing industry in Mexico is diverse and growing, including automotive, aerospace, electronics, and others. As a result of this diversification, we have access to a wide variety of materials sourcing opportunities. Additionally, Mexico has a well established supplier base, which can provide reliable and high-quality materials to a variety of industries.

The Mexican government is keen on attracting foreign investment and offers various incentives to support this objective, including tax breaks and financial support for infrastructure development. These incentives are particularly beneficial for materials sourcing for manufacturing in Mexico, as they reduce the overall cost of doing business, making the country an attractive destination for foreign manufacturers. In 2024, foreign direct investment in Mexico is projected to increase by 8%, according to the Mexican Business Council for Foreign Trade, Investment and Technology (COMCE).

In addition to its economic performance, good business climate, and increased trade, Mexico’s new political reforms and improved government stability are making it more attractive to foreign investors, especially manufacturing companies. According to the United Nations Conference on Trade and Development (UNCTAD), Mexico ranks 9th in the world for FDI investment.

Area Development:

The tax breaks help to reduce the burden of tax expenses, while financial support for infrastructure development helps to enhance transportation, communication, and energy networks. This creates an environment that is conducive to materials sourcing and manufacturing in Mexico. Overall, the Mexican government's initiatives to promote foreign investment have made the country an attractive destination for businesses seeking to source materials and manufacture products.

High-Quality Materials

Mexico is home to a range of industries, including automotive, aerospace, electronics, and more. As a result, there is a wealth of knowledge and experience in producing high-quality materials that meet international standards. Additionally, the country has implemented strict quality control measures, which ensure that the materials produced in Mexico meet the required specifications and standards. This means that businesses can source materials from Mexico with confidence, knowing that they are receiving high-quality products.

Skilled Workforce and Advanced Infrastructure

Mexico boasts a skilled workforce trained in the latest manufacturing technologies. The country has invested significantly in its industrial infrastructure, which includes modern facilities and advanced logistics networks. This ensures that your materials are handled with expertise and efficiency. Think of it as having a well-oiled machine working seamlessly to support your production needs.

Technology is transforming logistics services in Mexico by enabling more efficient, transparent, and responsive supply chain operations. The integration of sophisticated software and hardware solutions helps logistics companies manage inventory, optimize routes, and improve communication with customers and partners.

Medium

Ease of Doing Business

Mexico has made it easy for businesses to set up operations and source materials in the country. The Mexican government has implemented measures to streamline the process of starting a business, including reducing bureaucracy and offering support to foreign investors. Additionally, Mexico has a strong logistics infrastructure, including ports, highways, and railroads, making it easier for businesses to transport their goods across the country and beyond. According to a study by the University of Pennsylvania:

The potential impact of upgrading Mexico’s transportation and logistics infrastructure is huge, says Walter Kemmsies, chief economist at Moffatt & Nichol, an international port infrastructure consultancy. Long isolated by geography and poverty from the major currents of global trade and development, Mexico has entered a crucial stage in its development…Just as crucial, Mexico’s geographical position gives the country what Kemmsies calls “optionality,” which means that from a Mexican location, corporate exporters “can send goods to anywhere in the world,” from either the country’s Gulf coast — positioned close to the Panama Canal — or via the Pacific Ocean to a growing list of markets in Asia.

Source: Blacksmith International

Environmental Considerations

Sustainability is increasingly critical in today's business landscape. Sourcing materials for manufacturing in Mexico can contribute to your company's environmental goals. Shorter shipping distances mean reduced carbon emissions, and many Mexican suppliers are committed to eco-friendly practices. Partnering with NovaLink, a company that prioritizes sustainability, can enhance your green credentials.

Building Strong Relationships: The NovaLink Advantage

Navigating a new supplier landscape can be daunting. Here's where a nearshore partner like NovaLink excels. We have the experience and local connections to help you find the perfect fit. Our team acts as an extension of yours, bridging the language and cultural gap to ensure smooth communication and successful sourcing strategies.

Beyond Sourcing: A Holistic Approach to Manufacturing Success

NovaLink goes beyond simply connecting you with suppliers. We offer a comprehensive suite of services to streamline your entire manufacturing process in Mexico. From customs compliance to production management, we'll guide you through every step, ensuring a successful and cost-effective operation.

With our expertise and support, you can:

- Ensure compliance with regulatory requirements

- Develop a tailored supply chain strategy

- Access a skilled and flexible workforce

- Leverage advanced manufacturing technologies

Materials Sourcing for Manufacturing in Mexico: A Host of Advantages for Businesses

In conclusion, materials sourcing for manufacturing in Mexico offers many advantages, including competitive costs, favorable trade agreements, high-quality materials, and ease of doing business. As a result, businesses can benefit from reduced production costs, streamlined logistics, and access to high-quality materials, making Mexico an attractive location for materials sourcing.

FAQs on Materials Sourcing for Manufacturing in Mexico

1. What are the key advantages of sourcing materials for manufacturing in Mexico?

- Sourcing materials in Mexico offers cost savings due to lower labor and production costs, proximity to the United States, reduced shipping times, and access to a skilled workforce.

2. Are there specific industries that benefit the most from sourcing materials in Mexico?

- Yes, industries such as automotive, aerospace, electronics, and medical devices have particularly benefited from sourcing materials in Mexico due to its well-developed supply chain infrastructure.

3. How does Mexico's trade agreement landscape impact material sourcing?

- Mexico has numerous free trade agreements, such as USMCA, which provide favorable tariff rates and reduced trade barriers, making it an attractive choice for sourcing materials.

4. What considerations should businesses keep in mind when establishing material sourcing partnerships in Mexico?

- Businesses should consider factors like supplier reliability, quality control, legal compliance, and cultural differences when establishing material sourcing partnerships in Mexico.

5. Can you highlight any potential challenges associated with sourcing materials in Mexico?

- Challenges may include navigating complex regulations, managing cross-border logistics, and addressing language and cultural differences, which can be mitigated with careful planning and partnerships.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into sourcing in Mexico with our curated collection of related blog posts.

- How Mexico Is Strengthening Supply Chains for Long-Term Stability

- Is Your Supply Chain Ready for a Mexico Move?

- How to Streamline Supply Chains in Mexico Without Losing Your Mind (or Your Margin)

- The Most Overlooked Advantage of Mexico’s Logistics Infrastructure

- Stop Wasting Time—These Are the Fastest Trade Routes in Mexico