Last Updated on June 12, 2024

The global supply chain landscape is continually evolving, and Mexico has emerged as a key player. Mexican Supply Chain trends are increasingly positive, offering attractive opportunities for businesses looking to optimize their operations. In this blog post, we will explore why managing a supply chain in Mexico is easier and better than managing one from China, as well as present and future trends in the Mexican Supply Chain.

Positive Mexican Supply Chain Trends

Current trends driving the Mexican supply chain landscape will make the country an even more attractive destination for businesses seeking reliable and efficient supply chain solutions in the future.

There are several factors contributing to the positive trends in the Mexican Supply Chain:

A Shift Towards Nearshoring

The global supply chain landscape is witnessing a significant shift towards nearshoring, and Mexico is at the forefront of this trend. With its proximity to the US, Mexico offers a strategic advantage for companies looking to reduce lead times and transportation costs. This shift is driven by the need for greater agility, flexibility, and resilience in the face of global uncertainties.

Mexico's Strategic Location

Mexico's strategic location provides businesses with easy access to both North and South American markets.

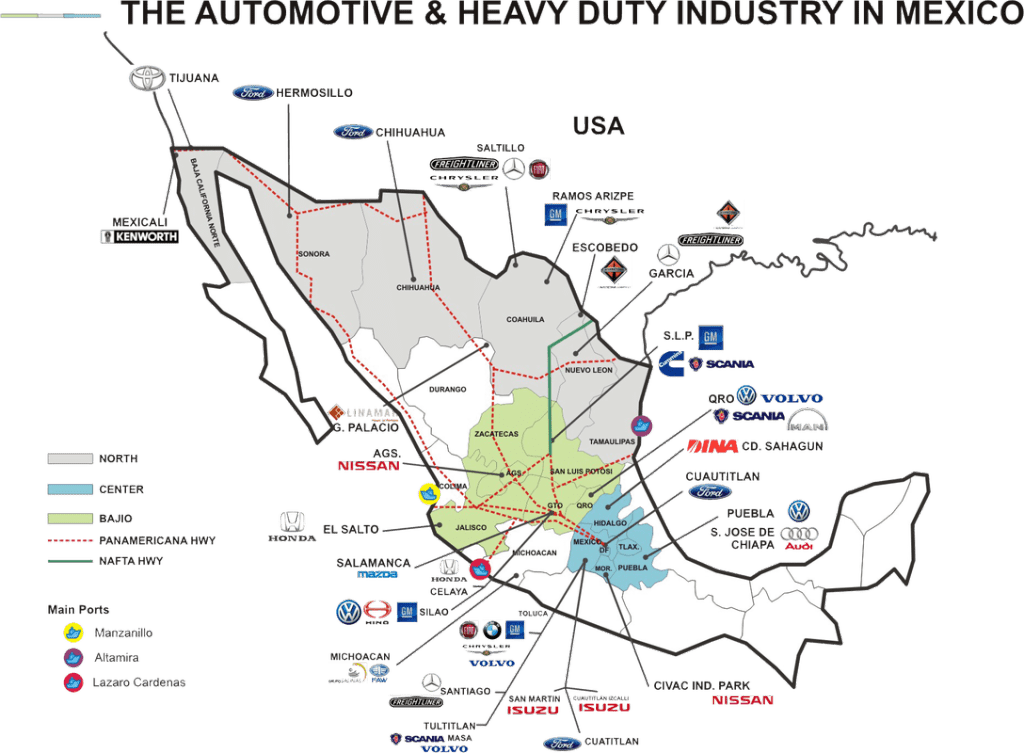

With a long coastline that stretches over 9,330 kilometers, Mexico has numerous ports that provide easy access to the Pacific Ocean, the Gulf of Mexico, and the Caribbean Sea. This makes it easy for companies to import and export goods to and from the Americas, as well as to other parts of the world. Mexico's shared border with the United States is another strategic advantage for businesses. The border is over 3,000 kilometers long, and it facilitates seamless cross-border trade and collaboration, particularly in the automotive, aerospace, and electronics industries.

Source: Mexico Projects Hub

Moreover, Mexico has over 80 airports, including major international airports in Mexico City, Cancun, and Guadalajara, which serve as key gateways to the Americas, Europe, and Asia. This makes it easy for businesses to transport goods and people, and to establish a global presence.

Competitive Labor Costs

Mexico offers a skilled and cost-effective workforce, with wages that are significantly lower than those in the United States, Canada, and Europe, which makes it an attractive location for manufacturing and assembly operations. Additionally, Mexico's labor laws are flexible, which allows businesses to adjust their operations according to their needs. According to the U.S. Department of Commerce:

Mexico offers a skilled and cost-effective workforce, with wages that are significantly lower than those in the United States, Canada, and Europe, which makes it an attractive location for manufacturing and assembly operations. Share on XMexico offers a large and low-cost labor force for manufacturing operations, with wage rates that are significantly lower than those in the United States, Canada, and Europe. The country's labor laws are also relatively flexible, allowing companies to adjust their operations to meet changing market demands.

Strong Manufacturing Capabilities

Due to Mexico's proximity to the United States, its manufacturing industry has grown rapidly. A significant number of U.S. companies have set up operations in Mexico in order to benefit from the lower labor costs in the country, which are usually a fraction of what they would pay in the United States, as well as favorable tax policies and access to the U.S. market. As a result of establishing operations in Mexico, U.S. companies are able to reduce their labor costs while maintaining close proximity to their U.S. customers.

Source: Mexico: an upcoming world power

Mexico's large number of free trade zones is another factor that has contributed to the growth of its manufacturing industry. Free trade zones are designated areas where businesses can set up operations and enjoy tax breaks, exemptions from import and export duties, and other incentives. Mexico has over 40 free trade zones, which are located near major ports and airports and offer easy access to global markets.

Trade Agreements and Economic Integration

Mexico is a member of numerous trade agreements, including the United States-Mexico-Canada Agreement (USMCA).

The United States-Mexico-Canada Agreement (USMCA) is a trade agreement between the United States, Mexico, and Canada that replaced the North American Free Trade Agreement (NAFTA). The USMCA is designed to modernize and update the rules governing trade and investment among the three countries, and it includes provisions aimed at improving the integration of supply chains in North America.

A number of factors contribute to the positive trend in Mexican supply chains as a result of the USMCA agreement. To begin with, it provides greater certainty and predictability for businesses operating in the region by establishing rules which protect intellectual property, promote digital trade, and create a level playing field for all businesses.

A number of factors contribute to the positive trend in Mexican supply chains as a result of the USMCA agreement. Share on XSecondly, the USMCA includes new provisions aimed at promoting regional supply chain integration, including rules of origin that incentivize the use of North American content in goods traded between the three countries. This means that businesses in Mexico may be able to benefit from increased demand for locally produced goods that meet the USMCA's rules of origin.

Infrastructure Improvements

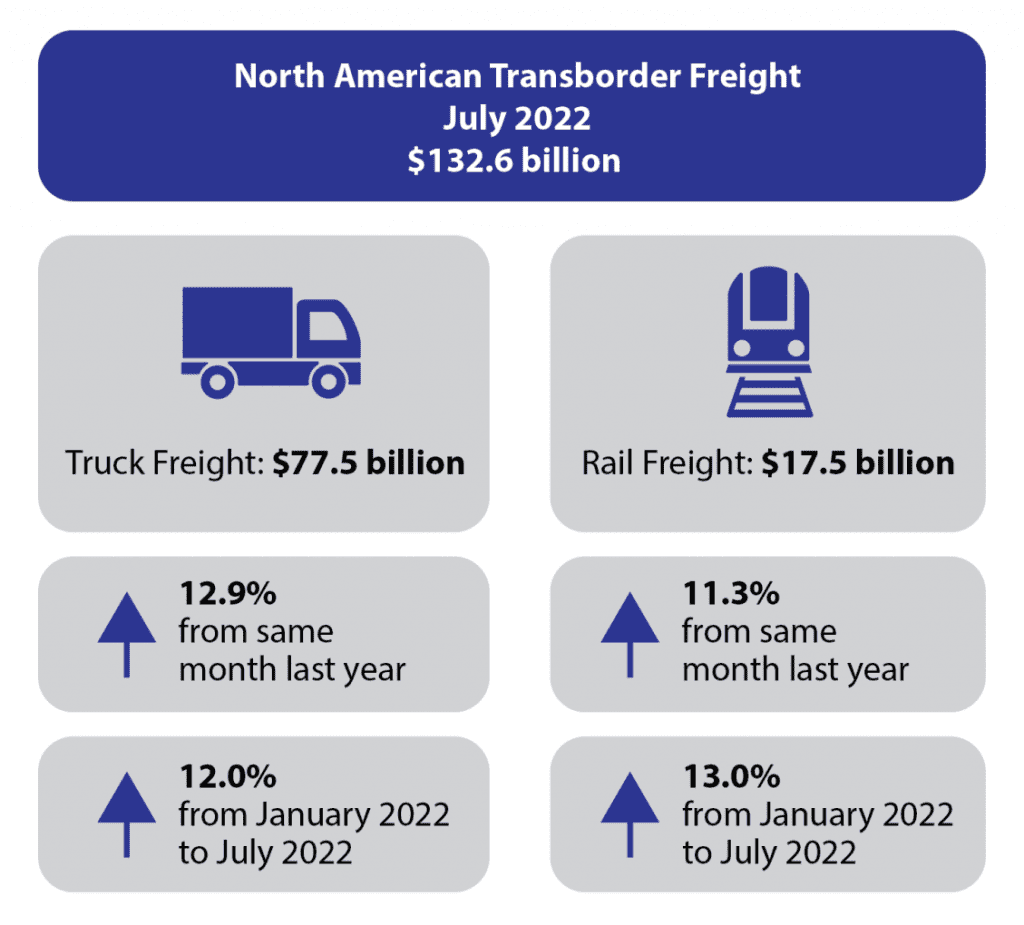

The Mexican government has made significant investments in infrastructure, including ports, roads, and railways, to support the growth of the country's manufacturing and logistics sectors.

These improvements have increased the efficiency and reliability of the Mexican Supply Chain, making it an attractive option for businesses seeking to optimize their operations.

According to the US Department of State:

Mexico has made significant investments in infrastructure, including ports, highways, and railways, to support the growth of its manufacturing and logistics sectors. These improvements have made Mexico's supply chain more efficient and reliable, making it an attractive option for businesses seeking to optimize their operations

Comparing Mexican and Chinese Supply Chains

While China has long been the go-to destination for manufacturing and supply chain management, Mexico's advantages are becoming increasingly apparent. Here are some reasons why managing a supply chain in Mexico is easier and better than managing one from China.

The importance of resilient supply chains has also been made abundantly clear in light of the impact of COVID-19, and as competition with China exposes vulnerabilities to relying on Chinese supply chains. The Biden administration has ordered a review of U.S. supply chains, with the objective of decreasing American dependence on Chinese production of critical inputs. Integrated North American supply chains could provide a viable alternative to Chinese manufacturing and allow some critical industries to move production closer to home.

Brookings Institute

Reduced Shipping Costs

One of the biggest advantages of managing a supply chain in Mexico is reduced shipping costs. Mexico is much closer to the United States than China, which means that shipping times and costs are significantly lower. Additionally, Mexico's proximity to the United States means that businesses can take advantage of land transport options, which are typically faster and more cost-effective than air or sea transport.

Source: Bureau of Transportation Statistics

Improved Quality Control

Managing a supply chain in Mexico also allows businesses to have greater control over quality assurance. Mexico has strong quality control regulations, which are enforced by the government. Additionally, the country's proximity to the United States means that businesses can quickly and easily make site visits to ensure that their operations are meeting quality standards.

Managing a supply chain in Mexico also allows businesses to have greater control over quality assurance. Share on XFaster Time-to-Market

Mexico's proximity to the United States is a significant advantage for businesses, particularly in industries such as manufacturing and logistics. When compared to countries such as China, Mexico offers shorter shipping times and faster land transport options, which means that businesses can quickly respond to changes in demand and bring new products to market more quickly.

For example, if a company based in the United States wants to bring a new product to market quickly, manufacturing it in China would require a longer lead time to transport the goods by sea, customs clearance, and possible delays in transit. In contrast, manufacturing the same product in Mexico allows the company to transport the goods overland more quickly and efficiently, which means that they can get their products to market faster and respond to changes in demand more effectively.

Present and Future Trends in the Mexican Supply Chain

In light of Mexico's growing role in the global supply chain, there are several positive trends worth mentioning:

Increased Investment in Technology

One of the biggest trends in the Mexican supply chain is the increased investment in technology. Businesses are investing in advanced robotics, automation, and artificial intelligence to improve their operations and reduce costs. Additionally, the Mexican government has introduced several programs to encourage businesses to invest in technology, such as tax incentives and grants.

One of the biggest trends in the Mexican supply chain is the increased investment in technology. Businesses are investing in advanced robotics, automation, and artificial intelligence to improve their operations and reduce costs. Share on XOne example of the Mexican government's programs to encourage businesses to invest in technology is the National Council of Science and Technology (CONACYT) program. This program provides grants to small and medium-sized businesses in Mexico that are engaged in research and development activities. The grants can be used to cover a range of expenses, such as equipment purchases, salaries for researchers and technicians, and expenses related to patents and intellectual property.

Another example is the Technological Innovation Fund, which provides funding for businesses to develop and implement new technologies. This fund is managed by the Mexican Ministry of Economy and is available to businesses of all sizes.

Talent Acquisition and Development

As the Mexican Supply Chain continues to evolve, the need for skilled professionals has become more pressing than ever. Companies are now investing in talent acquisition and development programs to bridge the skills gap and build a workforce capable of driving innovation and growth.

Greater Focus on Sustainability

Another trend in the Mexican supply chain is the greater focus on sustainability. Environmental concerns are increasingly influencing supply chain decisions, and Mexico is no exception. Businesses are implementing environmentally friendly practices, such as reducing waste and using renewable energy sources. Additionally, the Mexican government has introduced regulations to encourage sustainable practices, such as the carbon tax and the National Strategy for Circular Economy.

Growing E-commerce Market

The e-commerce market in Mexico is growing rapidly, which is driving demand for efficient and reliable supply chain operations. The increasing popularity of online shopping has led to the growth of logistics and fulfillment centers in Mexico, as businesses look to meet the demands of consumers who want their products delivered quickly and efficiently. This trend is expected to continue as more consumers turn to online shopping. According to Export Development Canada:

The e-commerce market in Mexico is growing at a rapid pace, driving demand for efficient and reliable supply chain operations. As online shopping becomes more popular in the country, businesses are setting up logistics and fulfillment centers to meet the demands of consumers who want their products delivered quickly and efficiently. This trend is expected to continue in the coming years, as more consumers turn to online shopping for their purchasing needs.

Nearshoring and Reshoring

The COVID-19 pandemic has brought into sharp focus the risks associated with long and complex global supply chains. Businesses that rely on the sourcing and manufacturing of products overseas have been adversely affected by disruptions in transportation, labor, and supply chains. Consequently, many companies are seeking to reduce their exposure to risk and increase the resilience of their supply chains by reshoring or nearshoring their manufacturing operations.

many companies are seeking to reduce their exposure to risk and increase the resilience of their supply chains by reshoring or nearshoring their manufacturing operations. Share on XThe practice of nearshoring refers to the relocation of manufacturing operations closer to the end market, typically within the same region or continent. Mexico is well-positioned to benefit from this trend, as its proximity to the United States makes it an attractive option for businesses seeking to shorten their supply chains. Companies can reduce transportation costs and lead times by relocating manufacturing operations to Mexico, as well as improve their ability to respond to market conditions.

Digitalization and Industry 4.0

Digitalization is revolutionizing the Mexican Supply Chain, enabling real-time visibility, traceability, and predictability. The adoption of technologies like blockchain, IoT, and AI is streamlining processes, reducing inefficiencies, and improving overall supply chain resilience. This digital transformation is also fostering collaboration and data-driven decision-making among stakeholders. According to Deloitte:

Mexico has recognized the importance of digital transformation in industry and has implemented policies to support the development of Industry 4.0. The government has introduced tax incentives for businesses that invest in research and development and has created centers of excellence to promote the adoption of advanced manufacturing technologies. These efforts are expected to drive continued investment in Industry 4.0 technologies in the Mexican supply chain.

The Mexican Supply Chain Is a Positive Trend in the Global Economy

The Mexican Supply Chain offers numerous advantages for businesses looking to optimize their operations, from reduced transportation costs and competitive labor rates to a favorable trade environment and improved infrastructure. As a result, managing a supply chain in Mexico is increasingly seen as easier and better than managing one from China. With present and future trends pointing towards continued growth and innovation in the Mexican Supply Chain, businesses that capitalize on these opportunities will be well-positioned for success in the global marketplace.

Government Incentives for Reshoring in Mexico

By strategically aligning with the global trend of reshoring, leveraging Mexico's proximity to the U.S., benefiting from favorable trade agreements like the USMCA, and tapping into cost advantages, companies can position themselves for sustained success. This white paper explores the nuanced details of government incentives in Mexico. It will provide a comprehensive guide for businesses navigating reshoring opportunities. Fill out the form to receive the white paper today.

FAQ's on the Mexican Supply Chain

1. What are the key areas of untapped potential in the Mexican supply chain? The Mexican supply chain holds untapped potential in various areas such as technology integration, logistics optimization, sustainable practices, and fostering closer collaboration between manufacturers, suppliers, and distributors.

2. How is technology integration influencing the evolution of the Mexican supply chain? Technology integration, including the use of IoT (Internet of Things) devices, AI-driven analytics, and automation, is streamlining operations, enhancing real-time visibility, and enabling predictive maintenance. These innovations are optimizing supply chain efficiency and reducing costs for Mexican businesses.

3. What sustainable practices are emerging in the Mexican supply chain? Sustainability is gaining traction in the Mexican supply chain, with a focus on eco-friendly packaging, energy-efficient transportation, and responsible sourcing. Initiatives to minimize waste and carbon footprint are not only ethically sound but also align with global trends and consumer preferences.

4. How are partnerships and collaboration reshaping the Mexican supply chain landscape? Partnerships and collaboration between manufacturers, suppliers, and distributors are becoming more crucial in the Mexican supply chain. By sharing information, resources, and insights, businesses can achieve better demand forecasting, optimize inventory levels, and respond more effectively to market fluctuations.

5. What role does the e-commerce boom play in shaping the future of the Mexican supply chain? The e-commerce boom is reshaping the Mexican supply chain by increasing the demand for efficient last-mile delivery, warehousing solutions, and inventory management. This trend is driving the need for adaptable and agile supply chain models to meet changing consumer expectations.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.