Last Updated on August 14, 2025

You’ve probably heard it from peers—or maybe you’re feeling it firsthand—labor shortages in manufacturing are no longer a temporary blip. For small and medium-sized enterprises (SMEs), they’re a daily reality that slows production, drives up costs, and keeps you up at night. Finding and keeping skilled workers has become harder than ever, and it’s not just about filling positions—it’s about finding the right people with the right skills.

But here’s the good news: there are ways around it. And one of the most effective? Moving part of your operations closer to home, specifically to Mexico, with the help of an experienced nearshore manufacturing partner like NovaLink. Let’s break down why the shortage exists, how it’s impacting SMEs, and why Mexico might be the relief valve you’ve been looking for.

Why Are We Running Out of Manufacturing Workers?

The reasons aren’t simple—or new. But together, they’ve created a perfect storm for manufacturers.

1. The Demographic Squeeze

The U.S. workforce is aging out. As veteran employees retire, younger generations aren’t stepping into those roles fast enough. Between 2000 and 2022, the median U.S. age went up by 3.4 years, and the share of working-age adults fell from 67.3% to 64.9%. That’s not just a statistic—it’s a gap you can feel on the factory floor.

The US manufacturing industry is facing a perfect storm of demographic, economic, and societal challenges that have contributed to labor shortages. Among the most pressing issues is the retirement of baby boomers. This generation represents a significant portion of the current manufacturing workforce, with nearly 25% of workers over 55. - Manufacturing Today

2. Skills Mismatch

Factories don’t look like they did 20 years ago. Automation, robotics, and data-driven production have raised the bar for technical skills. SMEs often struggle to find candidates who can program a CNC machine in the morning and troubleshoot a sensor system in the afternoon.

3. The Pandemic Hangover

COVID-19 pushed many manufacturing workers out of the sector for good—some due to safety concerns, others because they found opportunities elsewhere. The aftershocks are still rippling through the labor pool.

4. Big Players Outbidding Smaller Ones

Large corporations can lure talent with bigger salaries, signing bonuses, and on-site perks that SMEs can’t easily match. It’s hard to compete for talent when the playing field isn’t level.

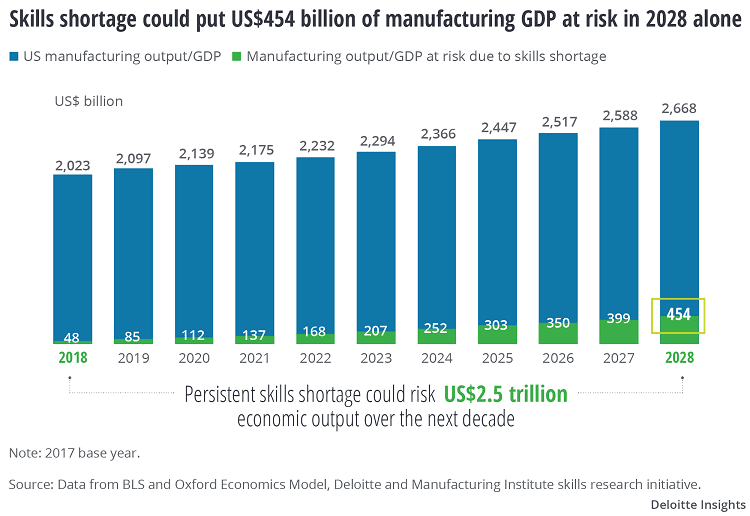

Left unabated, the manufacturing skills gap — which is now anticipated to leave 2.1 million jobs unfilled by 2030 — could cost the U.S. economy as much as $1 trillion. - AP News

What It’s Doing to SMEs

If you run a small or mid-sized operation, the effects are painfully clear:

- Production Bottlenecks – Orders back up, delivery times stretch, and customers start looking elsewhere.

- Higher Labor Costs – Overtime, retention bonuses, and wage hikes eat into margins.

- Innovation Slowdown – R&D takes a back seat because all your energy is spent just keeping up with orders.

- Losing Ground – Competitors with more stable staffing can respond faster and win contracts you can’t.

Why Mexico Is a Strategic Answer

Nearshoring manufacturing to Mexico isn’t about offloading your problems—it’s about building a stronger foundation for growth. And when you do it with a partner like NovaLink, you get more than a factory—you get a full support system.

Here’s why Mexico is hitting the sweet spot for SMEs dealing with labor shortages:

Proximity That Matters

Being next door to the U.S. means you get faster shipping, lower transportation costs, and shorter lead times. If you’re running a Just-in-Time model, that’s a huge advantage.

How Far Away is Brownsville?

Refer to the list below to determine how far away Brownsville is from most major U.S. cities.

City

Albuquerque

Atlanta

Boston

Chicago

Dallas

Denver

Detroit

Houston

Kansas City

Las Vegas

Los Angeles

Minneapolis

New York

Oklahoma City

Phoenix

San Diego

Seattle

St. Louis

Distance

992 mi

1,145 mi

2,196 mi

1,489 mi

559 mi

1,218 mi

1,744 mi

353 mi

1,101 mi

1,557 mi

1,632 mi

1,537 mi

1,982 mi

755 mi

1,259 mi

1,606 mi

2,436 mi

1,193 mi

Trade-Friendly Environment

The USMCA keeps trade friction low and tariffs minimal, making cross-border production more predictable and cost-efficient.

A Skilled and Expanding Labor Force

Mexico isn’t just about low-cost labor—it’s about the right labor. Technical schools and vocational programs are producing workers who can run advanced machinery, follow strict quality standards, and adapt to modern manufacturing demands.

Cost-Competitiveness Without Sacrificing Quality

Labor costs are lower than in the U.S., but quality standards remain high. This means SMEs can scale production without burning through cash reserves.

Shared Work Culture and Language Skills

Cultural alignment matters. Mexican teams often bring the work ethic, adaptability, and bilingual skills that make collaboration smooth and efficient.

Built-In Risk Diversification

If all your manufacturing is in one country, you’re exposed to every disruption that happens there. Splitting operations between the U.S. and Mexico gives you a buffer against labor disruptions, supply chain hiccups, or regulatory changes.

Why Partnering with NovaLink Changes the Game

Nearshoring works best when you’re not starting from scratch. NovaLink has spent decades building the infrastructure, recruiting networks, and compliance know-how that SMEs need to get up and running quickly. Instead of spending months figuring out permits, HR, and supply chain logistics, you can plug into an existing system that’s already proven to work.

They don’t just find you a building and walk away—they manage staffing, training, compliance, and production oversight. That means fewer headaches for you and a faster path to consistent output.

Final Thoughts

Labor shortages in manufacturing aren’t going away anytime soon, but they don’t have to dictate your future. By working with a trusted nearshore partner like NovaLink, SMEs can tap into Mexico’s skilled workforce, cut lead times, reduce costs, and protect against disruptions. The sooner you adapt, the sooner you can get back to focusing on growth instead of scrambling for staff.

FAQs: Labor Shortages in Manufacturing and Nearshoring to Mexico

1. What exactly is nearshoring?

It’s moving your manufacturing operations to a nearby country to reduce costs, shorten supply chains, and improve responsiveness. For U.S. companies, Mexico is a prime choice.

2. Are labor shortages in manufacturing a worldwide problem?

Yes. Aging populations, skills gaps, and post-pandemic workforce shifts are affecting manufacturers globally—not just in the U.S.

3. How is nearshoring different from offshoring?

Nearshoring means working with a neighboring or nearby country, often with similar time zones. Offshoring typically involves much farther destinations.

4. What risks come with manufacturing in Mexico?

Risks can include regulatory changes or supply chain disruptions. Partnering with an experienced company like NovaLink helps reduce these risks.

5. How do SMEs get started with nearshoring in Mexico?

Research potential locations, understand your production needs, and work with a reputable partner like NovaLink to handle workforce, compliance, and logistics.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into labor in Mexico with our curated collection of related blog posts.

- Mexico Rewards Manufacturing Companies That Commit: Here’s Why

- Can Moving Manufacturing to Mexico Really Be Turnkey? Here’s What You Need to Know

- 3 Hidden Costs You’re Avoiding by Manufacturing in Mexico (And Why It Matters)

- Setup Process for Manufacturing in Mexico: What You Should Know About Timelines, Permits, and Common Pitfalls

- How U.S. Tariffs Are Reshaping Mexico’s Manufacturing Outlook