Last Updated on February 27, 2024

When establishing a manufacturing presence in Mexico, choosing the right location is a critical decision. This can significantly impact your business's success. With a growing economy and strategic geographical advantages, Mexico offers numerous opportunities for manufacturing companies. In this guide, we will explore strategies for selecting a manufacturing location that aligns with your goals and maximizes operational efficiency.

Understanding the Importance of Location

Why Does Location Matter?

The choice of manufacturing location affects cost, logistics, access to markets, and even skilled labor. It's a decision that can make or break your business venture.

Factors to Consider

Proximity to Suppliers: One of the first considerations in choosing a manufacturing location is proximity to suppliers. Raw materials, components, and parts availability is critical to efficient production processes. By establishing a manufacturing facility close to suppliers, a company can reduce transportation costs, minimize lead times, and ensure a stable supply chain. This proximity fosters stronger relationships with suppliers, leading to better collaboration and cost-saving opportunities.

Transportation Infrastructure: Transportation infrastructure in and around the chosen location plays a pivotal role in manufacturing logistics. Adequate road networks, ports, airports, and railways are essential for smooth goods movement to and from the facility. Efficient transportation systems reduce shipping costs, decrease transit times, and enhance operational efficiency. It also enables timely delivery to customers, contributing to customer satisfaction and retention.

Labor Availability: A skilled and reliable workforce is the cornerstone of successful manufacturing. Assessing labor availability in the chosen location is crucial. Factors such as the local labor pool's size, skills, and wage expectations should be carefully considered. Labor shortages can lead to production delays and increased labor costs, so it's essential to choose a location where a suitable workforce is readily available or can be trained.

Regulatory Environment: The regulatory environment in a manufacturing location can significantly impact operations. Different regions may have varying tax structures, labor laws, environmental regulations, and safety standards. Understanding and complying with these regulations is essential to avoid legal issues, fines, and disruptions. Companies must conduct thorough due diligence to ensure their manufacturing processes align with local laws and standards.

Cost Considerations: Beyond the factors mentioned, it's essential to evaluate the overall cost implications of each potential manufacturing location. This includes not only production costs but also indirect expenses such as utilities, taxes, and insurance. A comprehensive cost analysis should encompass all relevant aspects to determine the cost-effectiveness of each location option.

A key factor to keep in mind is that site selection is a long-range decision. Once you’ve chosen where to situate a manufacturing plant, it’s unlikely you’ll pick up stakes and move anytime soon, barring some catastrophic event. So while present considerations will influence the decision, always keep an eye on the future as well.

How To Choose A Location For Your New Manufacturing Plant

Conducting a Location Analysis For Selecting the Ideal Manufacturing Location

To make an informed choice for selecting a manufacturing location, a comprehensive location analysis is essential. This process involves evaluating numerous factors to identify the ideal location for your manufacturing facility.

There are many factors that can determine where an organization will locate its facilities. For any given situation, some factors become more important than others in how facility location affects an organization’s performance. For example, when a company needs to open a new manufacturing facility, there are several factors that determine which location reduces the company’s operating costs while providing a great level of responsiveness to the market.

Seneca College: Introduction To Operations Management

- Define Your Objectives: Before delving into location analysis, it's crucial to establish clear objectives. Consider what you aim to achieve with your manufacturing facility. Are you seeking cost-efficiency, proximity to markets, or access to specific resources? Defining your goals will help you focus on the factors that matter most to your business.

- Identify Candidate Locations: Once your objectives are clear, identify potential locations that align with your goals. Consider domestic and international options, and create a list of candidate locations for further evaluation.

- Evaluate Proximity to Suppliers: Proximity to suppliers is critical. Assess the availability of raw materials, components, and parts at each location. Being close to suppliers can reduce transportation costs, minimize lead times, and ensure a stable supply chain.

- Assess Transportation Infrastructure: Selecting a manufacturing location means you must evaluate the transportation infrastructure in each location. Road networks, ports, airports, and railways are essential for efficient logistics. A well-connected location can reduce shipping costs, enhance supply chain flexibility, and improve customer satisfaction.

- Analyze Labor Availability: Skilled labor availability is crucial to manufacturing success. Evaluate the local labor pool's size, skills, and wage expectations. Labor shortages can lead to production delays and increased costs, so choose a location where a suitable workforce is available or can be trained.

- Understand the Regulatory Environment: Each location may have different regulatory requirements. Study local tax structures, labor laws, environmental regulations, and safety standards. Compliance with these regulations is vital to avoid legal issues and ensure smooth operations.

- Conduct a Cost Analysis: Consider both direct and indirect costs associated with each location. Calculate production costs, utilities, taxes, and insurance expenses. A comprehensive cost analysis will provide insights into each option's financial viability.

- Evaluate Market Access: If your product has specific target markets, assess the proximity to those markets. Being close to your customers can reduce transportation costs, enhance delivery times, and foster stronger customer relationships.

- Consider Risk Factors: Evaluate potential risks associated with each location, such as natural disasters, political stability, and economic conditions. Developing a risk mitigation strategy is essential to safeguarding your operations.

- Seek Local Expertise: Engage with local experts and consult industry associations to gather insights into the business climate, labor market, and regulatory landscape in each location.

- Conduct Site Visits: Whenever possible, visit potential locations to get a firsthand feel for the environment and assess local conditions.

Considerations For Selecting the Ideal Manufacturing Location in Mexico

Selecting a manufacturing location in Mexico requires careful consideration of several key factors:

Proximity to Markets: The first factor to evaluate is proximity to your target market. Mexico's extensive border with the United States makes it an attractive option for businesses aiming to serve the North American market efficiently. Consider whether you need easy access to the U.S., Canadian, or Mexican markets, and choose a location accordingly. Proximity to major international ports is also essential if your products are destined for global markets.

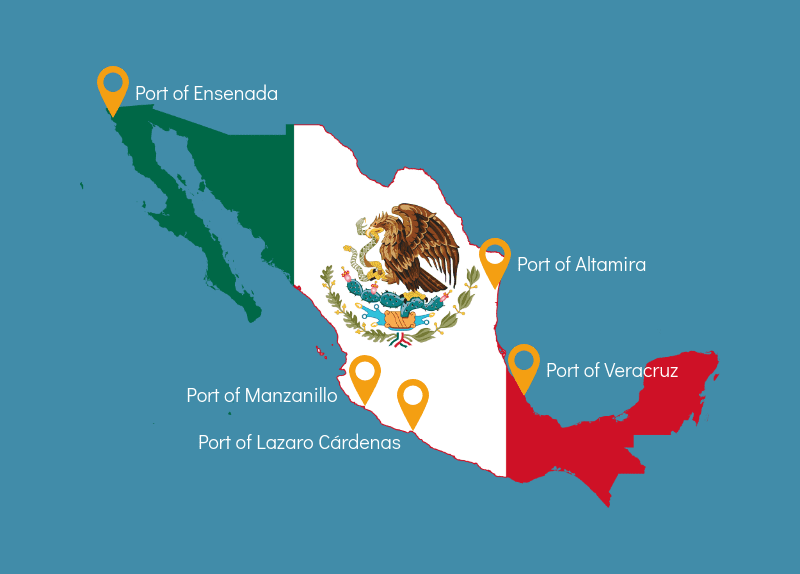

Major Ports in Mexico

Infrastructure and Transportation: Mexico offers a robust infrastructure and transportation network that makes it an attractive location for manufacturing. The country has made significant investments in recent years to improve its infrastructure, including roads, highways, ports, and airports. Mexico's extensive highway system connects major industrial hubs and border regions, facilitating the movement of goods within the country and to the United States and Canada through NAFTA (now USMCA) trade routes.

Labor Force and Skills: Mexico offers a skilled and diverse labor force across different regions. Assess the availability of the specific skills your manufacturing operations require. Regions like Baja California and Monterrey are known for their strong technical talent pool, while other areas excel in different skill sets. Consider labor market stability and wage expectations.

Cost Considerations: Cost efficiency is often a primary driver of Mexican manufacturing. Analyze labor costs, real estate prices, utilities, and tax structures in potential locations. Keep in mind that while certain regions may offer lower labor costs, they may also have higher operating expenses in other areas. A comprehensive cost analysis will help you make an informed decision.

Regulatory Environment: Mexico's regulatory landscape varies by region, affecting factors such as taxes, labor laws, environmental regulations, and safety standards. Ensure you understand local regulations and compliance requirements. Working closely with legal and regulatory experts is essential to avoid legal issues.

Industry Clusters: Consider industry clusters in different regions. Certain areas, like Guadalajara and Tijuana, have developed as specialized manufacturing hubs for specific industries like electronics and automotive. Being part of an industry cluster can offer advantages such as access to a skilled workforce and a robust supply chain ecosystem.

Risk Factors: Assess potential risks, including natural disasters, political stability, and security concerns. Develop a risk mitigation strategy to safeguard your operations at your chosen location.

Local Support and Incentives: Mexican states and municipalities offer incentives and support programs to attract foreign investment. Research whether your preferred locations provide any incentives, such as tax breaks or grants, to reduce your operational costs.

Mitigating Risks

Political and Regulatory Risks

Mexico's political landscape is dynamic, and regulatory changes may occur. To mitigate political and regulatory risks:

- Stay informed about local and national politics.

- Develop strong relationships with local government officials.

- Work with legal experts who specialize in Mexican regulations to ensure compliance.

- Diversify your investments across different regions to reduce dependency on a single location.

Security Concerns

Certain regions in Mexico face security challenges, including theft, extortion, and organized crime. To enhance security and reduce risks:

- Conduct thorough security assessments of potential locations.

- Ensure that local law enforcement and private security companies are well-coordinated.

- Put in place robust security measures, such as access control and surveillance.

- Consider locating your facility in safer regions or industrial parks with enhanced security.

Labor-Related Risks

While Mexico offers a skilled and cost-effective labor force, labor-related risks can include strikes, labor shortages, and disputes. To mitigate these risks:

- Establish strong relationships with labor unions and workers' associations.

- Ensure compliance with Mexican labor laws, including fair wages and working conditions.

- Cross-train employees to minimize the impact of labor shortages.

- Maintain open communication channels with your workforce to address concerns promptly.

Economic Volatility

Mexico's economy can be influenced by global economic trends and currency fluctuations. To manage economic volatility:

- Monitor exchange rates and consider hedging currency risks.

- Diversify your customer base to reduce dependency on a single market.

- Maintain financial flexibility and reserves to weather economic downturns.

Due Diligence and Legal Risks

Failing to conduct thorough due diligence can lead to legal and contractual risks. To mitigate these risks:

- Engage legal experts experienced in Mexican business law.

- Carefully review contracts and agreements with suppliers, partners, and government entities.

- Ensure proper documentation of all transactions and agreements.

Conclusion

Selecting the ideal manufacturing location in Mexico is a multifaceted process that demands careful planning and consideration. By defining your objectives, assessing regional differences, and mitigating risks, you can make an informed decision that sets your manufacturing venture up for success.

Choosing the right manufacturing location in Mexico is a crucial decision for companies seeking to expand their operations into this dynamic market. Working with a Nearshore manufacturing partner like NovaLink can provide significant advantages in this endeavor. NovaLink's local expertise and deep knowledge of Mexico's diverse industrial landscape can guide companies in identifying the ideal location that aligns with their specific needs. Their established network of facilities and relationships with local authorities streamline the site selection process, helping companies navigate regulatory requirements and access incentives effectively. NovaLink's proximity to the U.S. border also ensures efficient logistics and timely communication, reducing the challenges often associated with long-distance operations. Overall, partnering with NovaLink not only simplifies the selection of a manufacturing location in Mexico but also enhances the chances of long-term success in this competitive and growing market.

FAQs

1. What are the advantages of manufacturing in Mexico?

Mexico offers cost advantages, proximity to the U.S. market, a skilled workforce, and trade agreements that facilitate exports.

2. How can I assess labor availability in a specific location?

Conduct market research, connect with local labor agencies, and visit the area to gauge the labor pool's size and skills.

3. What legal considerations should I be aware of when setting up manufacturing in Mexico?

You should be aware of labor laws, tax regulations, import/export rules, and environmental regulations. Consulting legal experts is advisable.

4. Are there government incentives for manufacturers in Mexico?

Yes, various government incentives and programs exist to encourage foreign investment in Mexico, including tax incentives and grants.

5. Can I change my manufacturing location in Mexico later if needed?

Yes, it's possible to relocate, but it can be costly and disruptive. Therefore, thorough research and planning are crucial to avoid such situations.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.