Last Updated on May 7, 2025

You’ve seen it happen—one late shipment from Asia, and suddenly production halts. Customer orders get pushed. Profits shrink. Everyone scrambles. That’s supply chain volatility, and if you’re running a manufacturing business, odds are it’s already taken a toll.

The question isn’t whether disruptions will happen—it’s when. Labor shortages, port congestion, trade wars, pandemics… the list keeps growing. Global supply chains, once seen as a badge of efficiency, now feel more like ticking time bombs.

But here’s the thing: not all supply chains are created equal. And if you're still relying on offshore manufacturing in far-flung places like China or Southeast Asia, you’re gambling with distance, delays, and rising costs. There's a smarter, closer, more stable option: nearshore manufacturing in Mexico.

What is Nearshore Manufacturing?

Nearshore manufacturing is the practice of outsourcing manufacturing operations to a nearby country. Mexico is a popular destination for nearshore manufacturing in the United States due to its proximity and favorable business environment.

Why Supply Chain Volatility Isn’t Just a “Global” Problem—It’s Your Problem

Let’s break it down. What does volatility really look like?

- A critical component stuck at customs for two weeks

- A container stranded at sea due to a backup in the Suez

- Tariff spikes that make your profit margins evaporate overnight

- Factories closing with zero notice due to political unrest or pandemic lockdowns

Now multiply that across every supplier you rely on—and stretch it across 8,000 miles. You see the problem. Long-distance manufacturing isn’t just slow—it’s brittle.

And with U.S. tariffs on Chinese goods tightening the noose, it's not just delays you're facing—it’s costs, too.

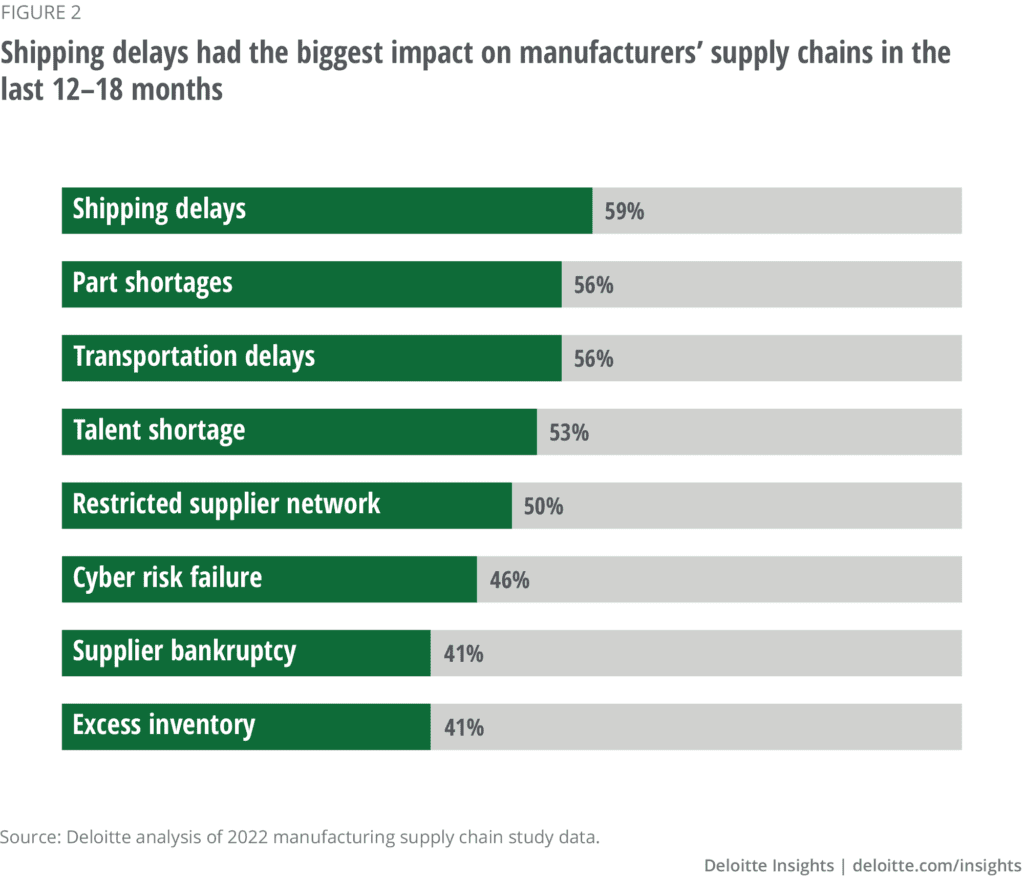

Deloitte Insights: Meeting the challenge of supply chain disruption

The Perplexity of Supply Chain Challenges

Navigating global supply chains is difficult. The interconnectedness of suppliers, manufacturers, and distributors can amplify disruption's impact. This perplexity often leaves businesses scrambling to find alternative solutions to keep production lines running smoothly.

The semiconductor chip shortage that hit the automotive industry in late 2020 highlighted two lessons in supply chain management.

The first is the lack of upstream visibility remains the Achilles heel of supply chains. Firms often do not know their suppliers beyond those in Tier 1 and are thus prone to shocks in the upstream supply chain.

The second is the supply chain of each firm is not isolated but is connected with other supply chains in a vast global network. This reality was made painfully apparent by the continuing shortages of semiconductors, when companies in different industries (e.g., automotive and consumer electronics) found themselves vying for chips from the same suppliers.

Harvard Business Review: Why It’s So Hard to Map Global Supply Chains

Burstiness: The Unpredictable Nature of Supply Chain Disruptions

Manufacturers across North America are waking up. Supply chain volatility is here to stay. But so is the solution.

We’re seeing companies shift everything from textile production to electronics assembly to Mexico—and not just for cost savings. They’re choosing predictability. Control. Speed.

When your operations are closer, you can pivot faster. You can troubleshoot in person. You can sleep at night knowing your supply chain won’t collapse because of a port strike in Asia.

McKInsey and Company: Future-proofing the supply chain

Nearshore Manufacturing: A Viable Solution

We get it—switching countries, even continents, can feel daunting. That’s why having the right partner matters more than ever.

NovaLink isn’t just a nearshore manufacturing company. We're a hands-on extension of your operation, helping you set up in Mexico without the typical red tape.

We handle:

- Site selection and setup

- Hiring and HR compliance

- Logistics and customs coordination

- Ongoing operational management

So you're not navigating a new landscape blind—you’re making moves with a local guide who knows the terrain.

And let’s not ignore the elephant in the room: tariffs on China. Companies working with NovaLink can bypass a huge chunk of those by shifting operations to Mexico, which enjoys tariff-friendly trade agreements with the U.S. That’s not just smart—it’s a competitive edge.

Proximity and Reduced Lead Times

One of the primary advantages of nearshore manufacturing is its geographical proximity to the United States, a major market for many industries. Reduced transportation distances translate to shorter lead times, minimizing delays caused by international shipping and customs processes.

Enhanced Flexibility and Responsiveness

Nearshore manufacturing allows increased flexibility and responsiveness to demand changes or unforeseen disruptions. Being closer to the production site enables manufacturers to adapt swiftly to market fluctuations, ensuring a more agile and resilient supply chain.

In many ways, the case is clear. Nearshoring or onshoring can contribute to risk-resistant supply chains and lead to faster time-to-market, more effective planning cycles, and greater flexibility in response to disruption. Proximate sourcing can enable greater control and more frequent site visits, fewer cultural barriers, and better communication. Reductions in logistics costs and lead times can also bolster the balance sheet by freeing up working capital that is tied up in cash outlays to suppliers and inventory in transit.

SAP Insights: Evaluating Nearshoring? Here are Five Realities

Cost-Effective Operations

While manufacturing in certain offshore locations might offer lower labor costs, nearshore manufacturing should not be overlooked. Reduced transportation costs and the ability to maintain tighter control over the production process contribute to a more sustainable and financially sound investment. In addition, labor costs in Mexico are very competitive with other destinations, such as China.

Engineering and Tech Talent

Mexico offers a large pool of engineering and tech talent, with over 847,000 students enrolled in an engineering or related program and granting 135,765 engineering degrees.

Making the Shift: Considerations for Nearshore Manufacturing

If you're contemplating the shift towards nearshore manufacturing in Mexico, there are several key considerations to remember.

- Evaluating Regulatory and Legal Frameworks: Before making decisions, it's crucial to understand Mexico's regulatory and legal frameworks. Familiarize yourself with local labor laws, trade agreements, and any other relevant regulations to ensure compliance and mitigate potential risks.

- Building Robust Partnerships: Choosing the right manufacturing partner is paramount to nearshore operations' success. Look for partners with a proven track record, strong references, and a commitment to quality and reliability.

- Investing in Technology and Infrastructure: To maximize nearshore manufacturing benefits, invest in technology and infrastructure that enhance efficiency and communication. This may include advanced manufacturing technologies, real-time tracking systems, and secure digital platforms for seamless collaboration.

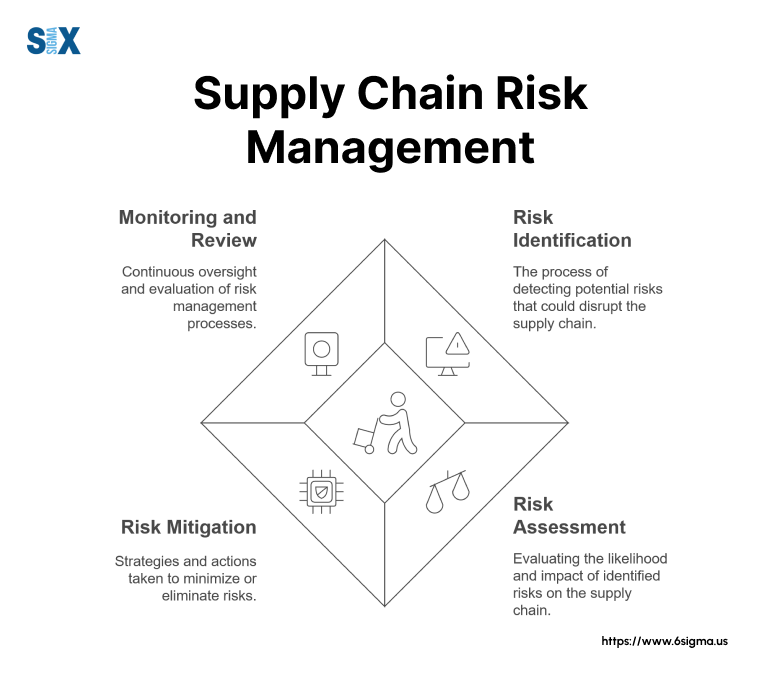

- Continuous Risk Management: Supply chain disruptions may still occur, albeit in smaller numbers. Implementing robust risk management strategies is essential to identify potential threats and proactively address them before they escalate.

Conclusion: Supply Chain Volatility Is the New Normal

In a world where supply chain volatility is the new normal, the shift towards nearshore manufacturing in Mexico presents a strategic opportunity for businesses to mitigate risks and secure their investments. By embracing the advantages of proximity, flexibility, and cost-effectiveness, manufacturers can navigate the complexities of the modern supply chain landscape with increased resilience.

Frequently Asked Questions (FAQs):

1. Is nearshore manufacturing only suitable for certain industries?

- No, nearshore manufacturing can be beneficial for a wide range of industries, including automotive, electronics, aerospace, and more. It offers advantages such as reduced lead times and increased flexibility that are valuable across various sectors.

2. How does nearshore manufacturing in Mexico compare to offshore alternatives in terms of cost?

- While offshore locations may offer lower labor costs, nearshore manufacturing in Mexico provides a more balanced cost-effectiveness, considering reduced transportation expenses and better control over the production process.

3. Are there any potential cultural or language barriers when working with manufacturing partners in Mexico?

- Nearshore manufacturing in Mexico often benefits from cultural and language affinity, as the country shares similar time zones and cultural understanding with the United States. This can lead to smoother communication and collaboration.

4. What steps can businesses take to proactively manage supply chain risks in a nearshore manufacturing setup?

- Businesses can implement continuous risk management strategies, including thorough evaluations of regulatory frameworks, building strong partnerships, investing in technology, and maintaining vigilant monitoring of potential disruptions.

5. Is nearshore manufacturing a suitable solution for small and medium-sized enterprises (SMEs)?

- Yes, nearshore manufacturing can be advantageous for SMEs, offering them the opportunity to benefit from proximity, flexibility, and cost-effectiveness. However, it's essential for SMEs to conduct thorough due diligence and choose manufacturing partners wisely.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.