Last Updated on December 11, 2024

When considering locations for your electronics manufacturing plant, you want a country that offers quality, cost-effectiveness, and proximity to your target market. Mexico stands out as an ideal location for your electronics manufacturing plant, and in this article, we'll explore why.

Strategic Location and Trade Agreements

Located just south of the US border, Mexico offers unparalleled access to the world's largest consumer market. With multiple trade agreements, including the United States-Mexico-Canada Agreement (USMCA), Mexico provides a seamless and tariff-free export process. This strategic location enables you to supply your products to the US market quickly and efficiently, reducing logistics costs and lead times.

Skilled Workforce and Competitive Labor Costs

Mexico boasts a large and skilled workforce, with a strong focus on STEM education. The country has invested heavily in technical training programs, ensuring a steady supply of qualified engineers, technicians, and production staff. Additionally, labor costs in Mexico are highly competitive, allowing you to maintain a cost-effective operation without compromising quality.

Mexico's STEM education has grown significantly over the last ten years, with an average of 130,000 engineers and technicians graduating annually. Mexico produces more STEM graduates per capita than the United States and is in the top 10 STEM graduate-producing countries in the world.

TechCrunch

World-Class Infrastructure and Logistics

Mexico's infrastructure supports international trade and commerce. With modern airports, seaports, and highways, you can easily transport your products and materials. The country has also invested in specialized industrial parks and clusters, providing a secure and efficient environment for your electronics manufacturing plant.

Government Incentives and Support

The Mexican government offers various incentives and programs to attract foreign investment, including tax breaks, training programs, and investment promotion schemes. These initiatives demonstrate the country's commitment to supporting your electronics manufacturing plant's growth and success.

Mexican Electronics Manufacturing Expertise

Mexico has a long history of electronics manufacturing, with many companies established in the country. This expertise translates to a strong focus on quality control, with many manufacturers holding international certifications such as ISO 9001 and IATF 16949. Mexico's quality control standards are on par with those in the US and Europe, ensuring your products meet the highest standards.

Mexico's Electronics Industry Is Versatile

Mexico's electronics manufacturing industry is also remarkably versatile. From flat-screen TVs, smart appliances and intricate circuit boards, it can produce a wide range of products. Businesses that manufacture different types of products to meet the needs of their customers rely on this versatility. In a dynamic business environment, companies are able to cater to diverse market segments as a result of the industry's ability to handle a wide range of products.

The Skilled and Experienced Advantages of Mexican Labor in Electronics Manufacturing

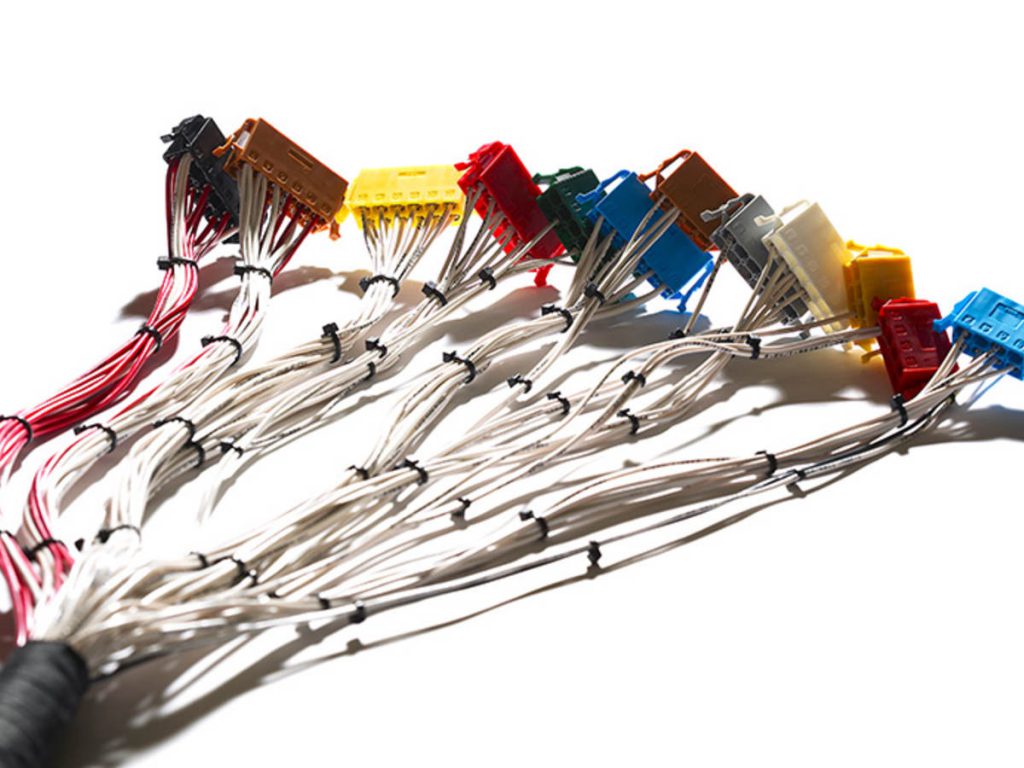

A typical electronics manufacturing worker in Mexico possesses a skill level for complex products that are difficult to source in other countries, especially when working on a product such as a wire harness. Moreover, the electronics workforce in Mexico offers the following advantages:

- Skills and Experience: Mexico has a large pool of electronics manufacturing workers. This is due in part to the long history of electronics manufacturing in the country, particularly along the US-Mexico border.

- Experienced Engineers: Mexican plants often have experienced engineers on staff who can analyze product designs, develop efficient production processes, and troubleshoot any issues. This ensures smooth transitions between different electronic products.

- Training Ability and Education: Mexico has a growing educational system focused on technical skills. This means there's a steady pipeline of workers trained on specific electronics manufacturing processes.

Electronics Manufacturing Plants in Mexico are Modern and Adaptable

Mexico's manufacturing plants have become particularly attractive for electronics due to a focus on modernization and adaptability:

Modern Facilities:

- Up-to-Date Infrastructure: Many Mexican plants, especially those catering to international companies, boast modern facilities with features like temperature and humidity control, cleanroom environments, and advanced security systems. These features minimize production errors and ensure product quality.

- Focus on Efficiency: Modern layouts and material handling systems optimize production flow, reducing waste and lead times. This allows for faster production cycles and quicker market response.

Cutting-Edge Equipment:

- Investment in Technology: Many Mexican plants invest heavily in advanced equipment like automated soldering lines, surface mount technology (SMT) machines, and precision testing equipment. This allows for high-volume production with consistent quality.

- Flexibility: Modern plants are equipped with a diverse range of machinery that handles various electronic components and assembly processes. This adaptability makes them suitable for a wide range of electronic products.

Examples of Adaptability:

- Shifting from Basic to Complex Products: Mexico has successfully transitioned from producing simpler electronics to more complex items like circuit boards and medical devices. This demonstrates its plants' ability to adapt to evolving technological demands.

- High-Volume vs. Low-Volume Production: Mexican plants can handle both high-volume consumer electronics production and low-volume runs for specialized equipment. This caters to a wide range of electronics manufacturers.

How Companies Can Stay Agile in the Evolving Electronics Industry

The electronics industry is continually evolving, and keeping your business agile in this landscape ensures your competitiveness. Here's how:

Leverage flexible service models

Flexible operational models are crucial. These services allow businesses to adapt quickly to market shifts, whether that involves ramping up production or pivoting away from existing strategies.

Focus on Scalable Solutions

As demand fluctuates, scalable solutions are key. Technologies and services that grow with your company prevent resource wastage and ensure efficiency.

Embrace transparency and strategic guidance

Transparency in operations strengthens trust and alignment between all stakeholders. Ensure you have clear communication and strategic guidance to pave the way for informed decision-making and efficient operations.

Plan for Growth and Transition

Be prepared to expand or transition away from existing models as needed. This foresight enables smooth scaling or phasing out activities without disrupting workflow or profitability.

NovaLink's Comprehensive Range of Wire Harness Manufacturing Services

NovaLink offers a comprehensive range of wire harness manufacturing services. With expertise in the field, NovaLink delivers tailored solutions to meet diverse customer needs. Some of the key services provided by NovaLink include:

Wire Harness Design

NovaLink's experienced engineers collaborate closely with clients to design customized wire harnesses that meet specific requirements. By leveraging their knowledge of industry standards and best practices, they ensure optimal performance and reliability.

Wire Cutting and Stripping

NovaLink utilizes cutting-edge equipment to precisely cut and strip wires, ensuring accurate lengths and consistent quality. This step is crucial for achieving proper connectivity and electrical performance in wire harnesses.

Terminal Crimping

Skilled technicians at NovaLink expertly crimp terminals onto wires, creating secure and reliable connections. This process is essential for guaranteeing the integrity and longevity of the wire harnesses.

Connector Assembly

NovaLink specializes in the assembly of various types of connectors, including complex multi-pin connectors. Their technicians ensure proper alignment and mating of connectors to achieve seamless integration within electrical systems.

Custom Labeling and Packaging

NovaLink provides custom labeling and packaging solutions to meet specific branding and logistical requirements. Proper labeling ensures easy identification and installation of wire harnesses, while tailored packaging ensures safe transportation and storage.

Value-added Services

In addition to wire harness manufacturing, NovaLink offers value-added services such as prototyping, kitting, and supply chain management. These services further streamline the manufacturing process and provide comprehensive solutions to clients.

Harness Testing and Inspection

NovaLink implements rigorous testing and inspection procedures to verify the functionality and quality of wire harnesses. This includes continuity testing, insulation resistance testing, and visual inspections to detect any potential defects or issues.

Conclusion: Mexico Is an Ideal Location for Your Electronics Manufacturing Plant

Mexico offers a unique combination of strategic location, skilled workforce, competitive labor costs, world-class infrastructure, electronics manufacturing expertise, and government support, making it the ideal location for your electronics manufacturing plant. By setting up your plant in Mexico, you can ensure high-quality products, reduce costs, and quickly supply your target market.

Frequently Asked Questions: Electronics Manufacturing Plant in Mexico

1. What kind of electronics products can be manufactured in Mexico?

Mexico has experience in manufacturing a wide range of electronics products, including printed circuit boards, semiconductors, and consumer electronics such as smartphones and laptops.

2. Are there any specific regulations or standards for electronics manufacturing in Mexico?

Yes, Mexico has adopted international standards and regulations, such as ISO 9001 and IATF 16949, to ensure quality control and compliance with global industry standards.

3. Can I find skilled labor in Mexico for specialized electronics manufacturing processes?

Mexico has a large and skilled workforce, with many engineers and technicians specializing in electronics manufacturing. The country also offers training programs to ensure a steady supply of qualified workers.

4. How do I get started with setting up an electronics manufacturing plant in Mexico?

You can start by researching government incentives and programs, consulting with industry experts, and visiting industrial parks and clusters to find the ideal location for your plant.

5. What kind of support can I expect from the Mexican government for my electronics manufacturing plant?

The Mexican government offers various incentives, training programs, and investment promotion schemes to support the growth and success of your electronics manufacturing plant. You can expect support with setup, training, and ongoing operations.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into more information about Mexico Manufacturing Facilities with our curated collection of related blog posts.

- Why Mexico Isn’t a Perfect Manufacturing Solution (and What That Really Means)

- Can Moving Manufacturing to Mexico Really Be Turnkey? Here’s What You Need to Know

- Setup Process for Manufacturing in Mexico: What You Should Know About Timelines, Permits, and Common Pitfalls

- Americans Say They Want More U.S. Factory Jobs—So Why Don’t They Want to Work in Them?

- Top 10 Well-Known American Companies in Mexico—Should You Be Next?

- Why Factories in Mexico Are the Preferred Choice for Nearshoring

- 5 Easy Steps to Move Your Production to a Mexican Factory

- 3 Key Benefits of Operating in Mexico’s Border Zone