Last Updated on April 3, 2025

If your company wants to start a manufacturing operation in Mexico, you've probably come across the term "tariffs" more than a few times. The trade relationship between the U.S. and Mexico has often been a roller coaster, with tariffs being the major loop-de-loop. But here’s the thing: The ongoing tariff battles aren’t just a political game—they’re real obstacles for companies looking to do business on either side of the border.

So, why is the U.S. vs. Mexico tariff situation a no-win for businesses? Let’s break it down and discuss how it impacts manufacturers like you—and why this is one battle you don’t want to get caught in.

A Quick Overview of Tariffs and Their Impact

Before we get into the weeds of how this impacts your business, let’s set the stage. Tariffs are taxes or duties placed on goods as they cross borders. When one country slaps a tariff on imports from another, it creates a ripple effect. This raises costs, complicating logistics, and often leading to price hikes for consumers. Simple, right?

But when the U.S. and Mexico get into a tariff spat, it’s not just the goods affected-it's the entire trade framework. Companies trying to start a manufacturing operation in Mexico can get caught in the crossfire of these political games, facing higher costs, delays, and uncertainty.

The U.S. vs. Mexico Tariff Tug-of-War

Let’s face it: the trade relationship between the U.S. and Mexico isn’t always smooth sailing. While both countries are major trading partners, political tensions have led to tariffs being imposed back and forth, sometimes on specific industries, sometimes on everything. For businesses that depend on a steady, predictable supply chain, tariff fluctuations can throw a major wrench into their plans.

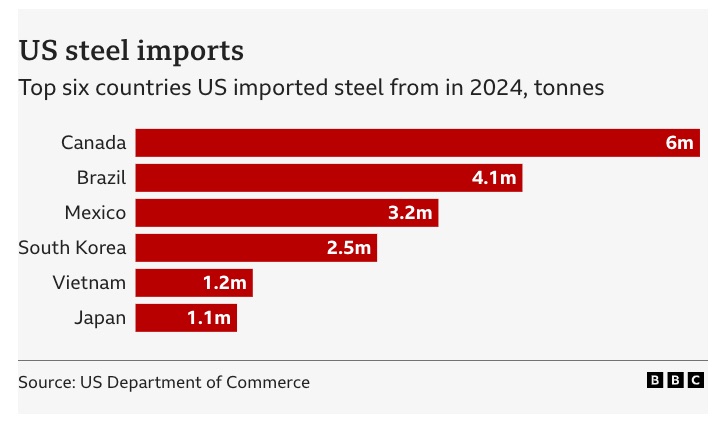

Take steel and aluminum tariffs, for instance. They’ve had a domino effect, raising raw materials costs, which increases production costs for Mexico-based companies. And don't get me started on the unpredictability. With trade agreements like NAFTA (now replaced by the USMCA) coming and going, it feels like the rules are constantly changing. This unpredictability makes it tough to plan long-term, which is a huge deal when setting up a manufacturing operation in Mexico.

How Tariffs Create a No-Win Situation for Companies

Now, let’s get into the meat of it: why is this a no-win scenario? Whenever tariffs are in play, companies have a few less-than-ideal options:

- Increased Costs If you’re importing raw materials from the U.S. or exporting goods back, tariffs raise prices. That means either you eat the costs (which eat into your profit margin) or pass them on to consumers (which could price you out of the market).

- Uncertainty in Supply Chains With tariffs being imposed and removed at a moment’s notice, it’s difficult to keep your supply chain stable. You might place an order today, but if tariffs are suddenly slapped on that product, your cost structure changes without warning.

- Political Uncertainty Mexico and the U.S. aren’t always in sync politically, and tariffs can get imposed as part of larger political negotiations. Businesses have to constantly stay on top of trade policies, which can change suddenly. This makes the long-term feasibility of setting up operations shaky at best.

- Impact on Customer Demand As manufacturers in Mexico face rising costs due to tariffs, finished products prices will rise. If the market can’t bear those increases, demand could fall, making your investment less profitable than you originally planned.

It’s this combination of high costs, unpredictable changes, and shifting market dynamics that makes starting a manufacturing operation in Mexico a gamble when tariffs are involved.

So, What’s the Solution?

Are we stuck? Is there no way around the tariff conundrum? Not exactly.

The key to navigating this uncertainty lies in flexibility. A strong network of local suppliers, diversifying your production sources, and working closely with trade experts can mitigate tariff risks. You may not be able to avoid political drama, but you can certainly stay one step ahead by building a resilient, flexible business model.

Here’s the thing: while tariffs add complexity, they also create opportunities. Companies that can navigate the shifting tariff landscape might be in a stronger position. They might be able to move quickly and adjust to international trade tides.

Conclusion

When starting a manufacturing operation in Mexico, tariffs are one of the critical factors to consider, but they shouldn’t be the only one. While the trade battle between the U.S. and Mexico seems like a no-win situation at times, it’s not a reason to abandon plans to move your business south of the border. Instead, focus on building flexibility into your operations, staying informed, and always being prepared to adjust to the changing landscape.

After all, Mexico offers compelling advantages beyond the tariff wars, like its strategic location, skilled labor force, and favorable trade agreements. So, don’t let the tariff drama deter you—just stay ahead of the curve, and you’ll be fine.

FAQs on Why the Tariff Battle Is a No-Win Situation for Companies Looking to Start a Manufacturing Operation in Mexico

1. How can I avoid the impact of tariffs when starting a manufacturing operation in Mexico? By working with experienced trade consultants and building relationships with local suppliers, you can minimize the risk of tariffs affecting your operations. Diversifying your supply chain and staying up-to-date on trade agreements will also help.

2. Do tariffs apply to all industries when manufacturing in Mexico? Not necessarily. Tariffs tend to target specific industries or products. However, the scope of tariffs can change depending on the political situation, so it’s important to stay informed about trade policies that impact your specific sector.

3. Is the cost of manufacturing in Mexico still competitive despite tariffs? Yes, manufacturing in Mexico remains competitive due to lower labor costs, proximity to the U.S., and favorable trade agreements like the USMCA. Tariffs may affect certain aspects of the supply chain, but the overall cost advantage can still make it worthwhile.

4. Will future changes in U.S. trade policy impact my decision to start a manufacturing operation in Mexico? Yes, trade policy changes can impact the cost of goods and the overall business environment. However, building flexibility into your business model can help you adapt to these shifts. It’s always wise to stay informed about potential changes to trade policies.

5. How can I prepare for future tariff changes when operating a manufacturing plant in Mexico? To stay ahead of the curve, regularly monitor trade negotiations between the U.S. and Mexico, and work with supply chain experts who can help you navigate any potential disruptions. Being proactive in adjusting your strategy is key to minimizing the impact of tariff changes.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.