Last Updated on April 24, 2025

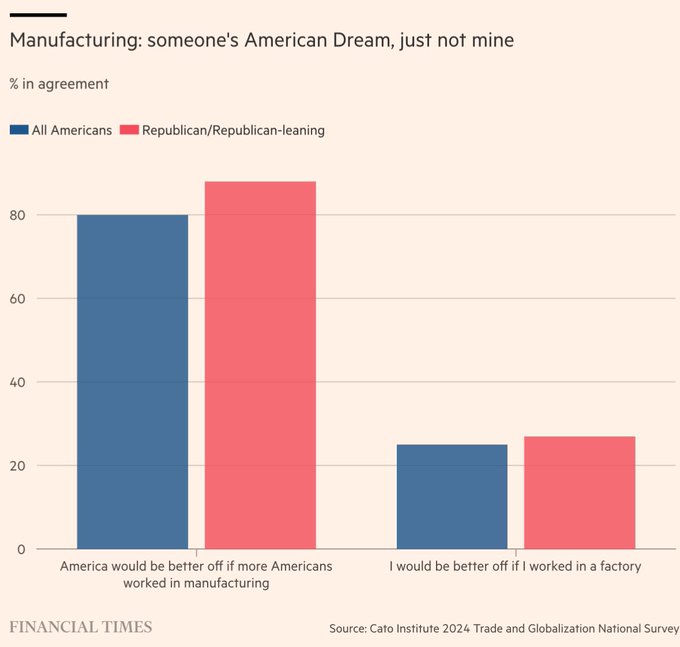

It’s one of those contradictions that makes you pause. Poll after poll shows strong support for bringing back U.S. factory jobs. There’s a nostalgic pride tied to manufacturing—the image of American steel, assembly lines humming, lunch boxes packed with sandwiches and grit. But in reality, most people don't want to work in these factories.

And that’s not just a quirky detail. It’s a reality that companies looking to manufacture goods need to understand—especially those eyeing reshoring strategies. Because when the local labor pool doesn’t want the work, where do you turn?

Let’s discuss that. And why so many are turning to Mexico—not as a second-best option, but as a smart, strategic move that actually works.

“Made in the USA” Sounds Great—Until It’s a Job Listing

There’s no denying it: "Made in America" optics still hold weight. Consumers love it. Politicians promote it. And businesses like the idea on paper. But on the ground, it’s a different story.

Manufacturing jobs in the U.S. remain unfilled alarmingly. According to the U.S. Chamber of Commerce, there are hundreds of thousands of manufacturing jobs that companies can't fill. Why? The reasons are pretty straightforward.

- Young workers don’t see U.S. factory jobs as attractive.

- Wages often don’t keep pace with physical demands.

- Automation is changing the nature of work, but not always in ways that make jobs easier.

Despite fears of job losses, the Manufacturing Institute and Deloitte project that 4.6 million manufacturing jobs will need to be filled over the next decade. Alarmingly, 2.4 million of these positions may remain unfilled due to skills gaps and demographic challenges. - Number Analytics

College-to-corporate pipelines are steadily being abandoned by Gen Zers, who are opting instead for trade schools and blue-collar jobs. While they're paying six-figure salaries to become electricians, plumbers, and carpenters, there's one thriving industry they're ignoring: manufacturing.

A Factory Without Workers Is Just an Empty Building

Companies need more than just honest intentions to operate efficiently. They need hands. Skilled ones. Reliable ones. People who take pride in producing something tangible—day in, day out.

And that’s where this whole conversation shifts.

Because while U.S. workers may be stepping back from the manufacturing floor, just south of the border, the story sounds very different.

Get Near Shore Manufacturing News from NovaLink

Level up your nearshore manufacturing strategy! 🚀 Subscribe to our newsletter for exclusive insights and stay ahead of the competition. Get:

✅ Expert analysis and the latest industry trends

✅ Updates on new blogs, videos, and resources

✅ Essential tools to drive your success

By submitting this form, you are consenting to receive marketing emails from: NovaLink. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Mexico: Not Just Nearby—Ready

Here’s the thing: Mexico isn’t a backup plan. It’s a ready-made solution that's proven itself again and again.

You’ve got a workforce that’s trained, enthusiastic, and, frankly, wants to work in factories. It’s a point of pride in many Mexican communities. These aren’t "leftover" jobs; they’re careers. And when you combine that attitude with technical skills, a strong work ethic, and affordable labor costs, you get a workforce that actually fits the needs of modern manufacturing.

Add in the benefits of the USMCA trade agreement—duty-free access to U.S. markets, stronger protections, and smoother logistics—and you’re not just saving on labor. You’re building something sustainable.

And we haven’t even reached geography.

It’s Not Offshore, It’s Next Door

Unlike offshore locations halfway around the world, Mexico offers proximity that’s difficult to beat. That means:

- Shorter shipping timelines

- Easy site visits and quality control

- Fewer supply chain headaches

Let’s say your operation is in Matamoros. You could have finished goods rolling into Texas in under 24 hours. Compare that to 30-45 days in Asia. It’s not just faster -- it's leaner. You hold less inventory. You react to demand faster. And when something goes wrong, you can be there the next day, not the next month.

It’s not a workaround. It’s an upgrade.

The Manufacturing Culture Still Lives--Just Across the Border

You know what? There’s something humbling about walking through a maquiladora in Mexico. You see workers who take pride in their workplaces. Supervisors who started out as operators. Training programs run by people who still remember what it’s like to stand on a line.

There’s no disconnect. No shrugging indifference. This is their industry.

And that kind of culture doesn’t just improve morale—it improves output. Quality. Consistency. Retention. Everything that matters to a manufacturing operation long-term.

What If the Future of “American Manufacturing” Isn’t Actually in America?

Now that might sound controversial. But think about it. If U.S. factory jobs are to keep production close, secure jobs, and maintain quality, Mexico checks all those boxes. All of them.

So maybe the future isn’t about drawing rigid national lines. Perhaps it’s about building regional partnerships that work. Maybe “Made near the USA” is just smart business.

America’s manufacturing industry has long relied on immigrant workers to take on the jobs that U.S.-born citizens don’t want to do. Deloitte’s research found that a decline in immigration in recent years has already strained the labor supply. Now, Trump’s crackdown on immigration and deportation efforts could set back the sector even more. - Fortune

Because let’s face it -- factories don’t run on headlines. They run on people. And Mexico has got the people. Skilled. Affordable. Available.

If you're a company trying to navigate the reshoring vs. nearshoring decision, this might be the clearest path forward. Not just because it’s cheaper. But because it works.

Conclusion: Support for U.S. Factory Jobs Is Real—but So is the Labor Gap

Yes, Americans still love U.S. factory jobs. But the sentiment doesn’t fill shifts or run machines. The labor gap is real—and growing. Meanwhile, Mexico offers what many U.S. cities can’t: a stable, skilled, and engaged workforce that actually wants the job.

Throw in favorable trade terms under the USMCA and the unbeatable convenience of nearshoring, and it’s clear why more manufacturers are shifting their focus south—not out of desperation, but out of smart strategy.

You can hold onto the values of American manufacturing without being limited by its current challenges. Mexico makes that possible. it’s cheaper. But because it’s working.

FAQs on U.S. Factory Jobs

Why don’t Americans want to work in factories anymore?

Many younger workers associate factory jobs with low pay, long hours, and limited career growth. There's also a perception issue—factory work just isn’t seen as “modern” or desirable, even though many roles now involve high-tech equipment and training.

How does Mexico compare to the U.S. in terms of factory labor quality?

Mexico offers a highly skilled labor force, especially in areas like electronics, automotive, textiles, and aerospace. Workers are trained, motivated, and accustomed to working in structured, high-volume environments—often with lower turnover than U.S. factories.

What is the USMCA, and why does it matter for manufacturing?

The USMCA (United States-Mexico-Canada Agreement) replaced NAFTA. It ensures tariff-free trade between the three countries and includes provisions that simplify logistics, protect intellectual property, and strengthen labor standards—all of which benefit manufacturers.

Is nearshoring to Mexico more cost-effective than reshoring to the U.S.?

In most cases, yes. Labor costs are significantly lower in Mexico, and operational expenses—from utilities to compliance—tend to be more manageable. Plus, proximity to U.S. markets cuts shipping costs and lead times dramatically.

What types of products are commonly manufactured in Mexico?

Mexico is known for producing everything from cars and aircraft components to electronics, textiles, and medical devices. Many global brands rely on Mexican factories for high-quality, high-volume production that stays close to the U.S. market.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.