Last Updated on February 26, 2024

If you're in the manufacturing industry, you've probably heard about the many advantages of sub-assembly manufacturing in Mexico. But what exactly is it, and why is it becoming increasingly popular among businesses worldwide? In this article, we will delve into the world of sub-assembly manufacturing in Mexico and explore the key benefits and reasons for its rising prominence in the global market.

Understanding Sub-Assembly Manufacturing

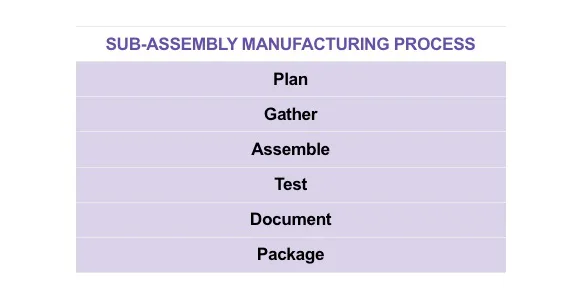

Sub-assembly manufacturing is a process in which individual components or parts are assembled separately before being integrated into the final product. This method can significantly streamline production processes and reduce lead times, making it an attractive option for businesses looking to optimize their operations. In Mexico, sub-assembly manufacturing has gained a reputation for being a cost-effective and efficient solution.

Usually the term “assembly” or simple assembly, is related only to the work in the main assembly. But those assembly tasks that may appear as only a small portion of the process may result in processes needed for improving the production of the final product. For example, this might include expediting the product flow by reducing waste which could be key to reducing the processing times. It might also include estimating the task times for the product and having preliminary operations ready or components complete in order to be incorporated to the final product. It's much more involved than just getting the components for a product and putting them together; there's a lot of analysis that goes into the flow of the assembly line and being able to see what processes work most efficiently. When you see the full picture of a Mexico manufacturing operation, you then have the ability to break it down to the smaller components to ensure that everything that you are adding to the product assembly is actually a value-added task.

Manuel Campos, Engineering and Information Systems Manager at NovaLink.

Why Choose Mexico for Sub-Assembly Manufacturing?

- Cost-Effectiveness: Mexico offers competitive labor costs, which can lead to substantial savings for manufacturers. Compared to other countries, such as China, Mexico's labor rates are highly competitive while still maintaining high-quality standards.

- Proximity to the U.S.: Mexico's geographical proximity to the United States provides a logistical advantage. This proximity reduces shipping costs, lead times, and allows for quick response times to market demands.

- Skilled Workforce: Mexico boasts a well-trained and skilled labor force. Many workers have experience in various manufacturing industries, making them proficient in sub-assembly processes.

- Quality Control: Mexican manufacturing facilities adhere to stringent quality control standards, ensuring that the sub-assemblies produced meet or exceed the required specifications.

- Government Support: The Mexican government actively promotes and supports the manufacturing industry, offering various incentives and support programs to encourage investment.

What Types Of Products Are Good Fits For Sub-assembly?

Sub-assembly manufacturing is a versatile process that can benefit a wide range of industries. It is particularly well-suited for products with complex structures or components that require precision assembly. Here are some examples of products that are good fits for sub-assembly:

1. Automotive Components: Sub-assembly is commonly used in the automotive industry for components such as engines, transmissions, and electronic systems. These complex systems often involve the assembly of numerous parts, and sub-assembly can streamline the manufacturing process.

2. Electronics and Electrical Devices: Products like smartphones, computers, and home appliances often consist of intricate electronic components. Sub-assembly can be employed to assemble circuit boards, connectors, and other parts, ensuring precise and efficient production.

3. Medical Devices: The medical industry relies on sub-assembly for products like surgical instruments, diagnostic equipment, and medical implants. Strict quality control and precision are crucial in this sector, making sub-assembly an ideal choice.

4. Aerospace Components: Aircraft and aerospace components demand high levels of precision and quality. Sub-assembly is used for items like avionics systems, landing gear, and hydraulics to meet the stringent standards of the aerospace industry.

5. Industrial Machinery: Complex machinery, such as construction equipment, printing machines, and industrial robots, often involve sub-assembly for efficiency and quality control.

6. Furniture and Cabinetry: Even in industries like furniture manufacturing, sub-assembly is useful. Components like drawers, hinges, and other intricate parts can be assembled separately before integrating into the final piece.

7. Consumer Goods: A wide range of consumer products, from toys to sporting equipment, benefit from sub-assembly. It allows for the efficient production of items with numerous components and moving parts.

8. Renewable Energy Products: Solar panels, wind turbines, and battery systems for renewable energy often include complex electrical and mechanical components, making sub-assembly a practical choice.

9. Telecommunications Equipment: Telecommunications equipment like routers, switches, and communication devices often require precision assembly, making sub-assembly an attractive option.

10. Appliances: Household appliances like refrigerators, ovens, and washing machines consist of various parts and components. Sub-assembly can help in optimizing the manufacturing process for these products.

In building or creating a medical pump there are many, many components and a great amount of time is spent having to reverse-engineer the product, to break-down all the components: the hoses, the valves, the electrical components, etc., to get a clear understanding of what is involved in making the pumps. They can be very complex.

Manuel Campos, Engineering and Information Systems Manager at NovaLink.

Is Sub-assembly Production Labor Intensive? Does It Need a Great Amount of Operators?

No, not necessarily. Imagine that you have a cardboard box sub-assembly process in place.

This sub-assembly might be broken down into smaller tasks after analyzing the process for making the final box: getting all the supplies together, making up the cardboard sheets, selecting the machine that can make the final product. When there is machinery involved, the labor portion is only for loading and unloading the sheets. In fact, there isn't much labor involved.

In other words, it depends on the industry and the product you're making to determine whether or not the process will be labor-intensive, semi-automated, or fully automated.

What is the most important thing a client needs to know or understand before a sub-assembly can be produced?

New prospects contacting NovaLink about reshoring manufacturing are going to be asked about their understanding of their existing supply chain first. What is the lead time of your vendors? Can you tell me about the capabilities of your vendors? Are there minimum quantities for key materials set by your vendors?

How will you purchase according to your manufacturing demands? As long as you are prepared for these questions and have the materials and availability in place, starting production at the factory is actually easy: we can support you in preparing for stock availability so that your line can run smoothly. If that knowledge isn't available, which usually gets done during the ramp up process, you may have lines down as a result of a lack of materials, or you may have a line down as a result of a product variation not considered at the start of the planning cycle.

A variation in a product does not mean there is a problem or obstacle in supplying materials. NovaLink can always help you overcome these obstacles. Material variation can be avoided as an obstacle if it is planned for in advance.

How well do you understand your bill of materials and manage waste and costs?

The assumption that buying a thousand pieces of X components will result in a thousand finished products is a common mistake. In most cases, though, waste will be generated by your suppliers and vendors, as well as by your execution process, which might be material- or manpower-related. It is necessary to apply new material once we start touching the material for producing the product to ensure high quality.

Variations of this type have the greatest impact on product production. As a manufacturing production plan optimizer, we always use our expertise: We can look at the production process and find ways to improve it; for instance, we may be able to reduce the time, adjust the criteria, or change the way the product is produced in order to improve it. Having machinery involved in the process, for example. When a customer launches a product for the first time, there is also the opportunity to optimize the final product definition. Interacting with the client provides us with the opportunity to explain why certain characteristics or features of the product can be modified to meet or exceed their expectations.

The Mexican Advantage: Sub-Assembly vs. Full Assembly

In a globalized economy, companies often have the choice between full assembly or sub-assembly manufacturing. Sub-assembly manufacturing in Mexico stands out as a preferred option due to the cost savings and efficiency it offers. Manufacturers can reduce overhead costs by outsourcing sub-assembly work, allowing them to focus on higher-level assembly or other core business functions.

A Win-Win for Manufacturers

Sub-assembly manufacturing in Mexico is a win-win for manufacturers. It not only saves costs but also enhances production efficiency, ensuring that final products meet high-quality standards. The benefits extend beyond cost savings, with shorter lead times, improved logistics, and the flexibility to adapt to changing market demands.

First of all, the pool of talent in Mexico is very diverse in its skillset. There have been many industries established in Mexico for many years and the workers here have experience with many of them. Over the last 20 years there have been industries in Mexico that are not only labor intensive, but also have a technical aspect that has been proven to be well executed in Mexico. Whether it is automatic electronic equipment or high power, industrial equipment, or the kind of IT-related things such as the assembling of computers, PCs, and main boards…Mexican labor is very skilled and able to adapt.

Manuel Campos, Engineering and Information Systems Manager at NovaLink.

Conclusion: Sub-Assembly Manufacturing in Mexico Is a Compelling Solution

In a competitive global market, sub-assembly manufacturing in Mexico provides a compelling solution for businesses seeking to improve their production processes while maintaining cost-effectiveness. The combination of skilled labor, proximity to the U.S., quality control, and government support makes Mexico an ideal choice for manufacturers looking to boost their competitiveness.

Sub-Assembly Manufacturing in Mexico FAQs

- What is sub-assembly manufacturing in Mexico? Sub-assembly manufacturing in Mexico is a process where individual components or parts are assembled separately before being integrated into the final product. It offers cost-effective and efficient solutions for manufacturers.

- Why is Mexico a preferred location for sub-assembly manufacturing? Mexico is preferred for sub-assembly manufacturing due to its competitive labor costs, proximity to the U.S., skilled workforce, quality control, and government support.

- How can sub-assembly manufacturing in Mexico benefit my business? Sub-assembly manufacturing in Mexico can benefit your business by reducing production costs, shortening lead times, improving logistics, and ensuring high-quality standards.

- Is quality control a concern in Mexican sub-assembly manufacturing? No, quality control is not a concern in Mexican sub-assembly manufacturing. Mexican facilities adhere to stringent quality standards to ensure the products meet or exceed specifications.

- Are there government incentives for manufacturers in Mexico? Yes, the Mexican government actively supports the manufacturing industry by offering various incentives and support programs to encourage investment.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.