Last Updated on March 26, 2025

Are you an entrepreneur looking to expand your manufacturing business? Seeking a location that offers competitive advantages, such as reduced costs and increased market access? Look no further than Mexico. In this article, we will explore how the US government is cutting red tape and simplifying the process for starting a manufacturing operation in Mexico. Discover how this initiative can help you tap into a thriving market, optimize your production, and achieve your business goals.

Starting Out: Do the Research and Legwork First

A manufacturing company in Mexico that does not have a clear business plan is likely to fail. Before you contact anyone about starting a manufacturing company, make sure that you have done your research and gathered the information you need. If you are familiar with the regulations and information you will need in advance, you will be able to navigate the rules and regulations between the U.S. and Mexico with much less difficulty. As a starting point, here are some suggestions:

- What kind of goods do you wish to make? Depending on the type of goods you want to make and how you want to import them back into the United States, there will be different issues involved. Determine the materials you will need is done through a bill of materials. The bill of materials (BOM) is an extensive list of raw materials, components, and instructions for producing your product.

Identifying the raw materials you need to manufacture your product is the next step. Import/export duties may be affected by the number of materials you import when manufacturing in Mexico. When you source raw materials locally, you'll pay fewer duties on your finished product. - Where do you want your manufacturing to be located? It's critical to consider where your manufacturing operations are located. If you want to ship frequently into the United States, you'll want to be near the US/Mexico border or near a port of entry. You may be required to observe local legislation in Mexico, depending on the city or state.

- When do you plan to start? The specifics of your manufacturing company in Mexico should be worked out and ready to go before you arrive if you want to get up and running right away. It may take several months or even a year, depending on the size of your business (if you attempt to do everything on your own). When working with a manufacturing partner, you can be up and running in as little as 30 days.

- Do you wish to start on your own or do you want to use a shelter model? A shelter manufacturing model allows foreign manufacturers to establish maquiladoras - or manufacturing facilities - in Mexico without having to undergo the formalities associated with establishing a Mexican corporation. Getting your manufacturing up and running in Mexico will be less expensive if you do everything yourself, but it will also be more time-consuming and difficult. When you attempt to navigate the Mexican government's procedures and norms on your own, you will likely make a number of mistakes. When you want to move things quickly, finding a manufacturing shelter partner in Mexico is a wise decision.

Advantages of Manufacturing in Mexico

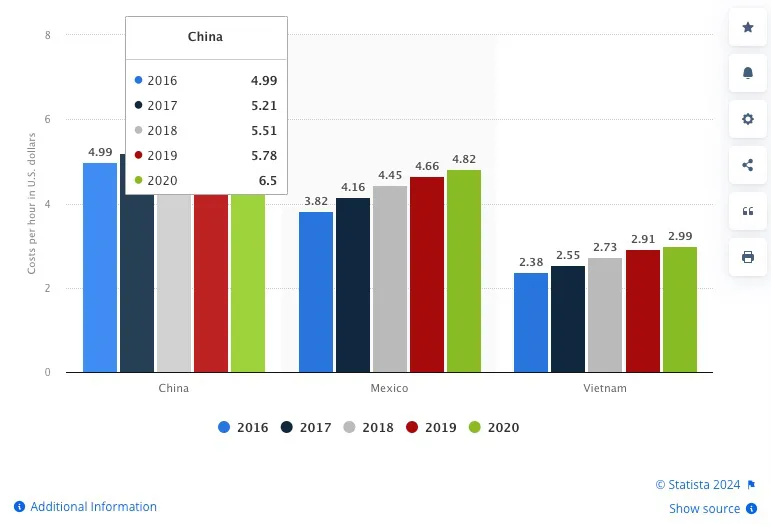

- Cost Efficiency Mexico's labor market presents significant cost advantages. Factory worker wages are approximately 20% of those in the United States, yielding substantial savings in labor-intensive industries.

- Skilled Workforce The country boasts a technically proficient labor force, ensuring high-quality production standards across various manufacturing sectors.

- Intellectual Property Protection Mexico maintains robust intellectual property laws, offering a secure environment for proprietary technologies and processes.

- Strategic Geographic Location Proximity to the United States facilitates expedited transportation of goods, with deliveries achievable within hours or days via road or rail, contrasting with the extended timelines associated with transoceanic shipments from Asia.

- Established Industrial Clusters Numerous industry clusters are strategically positioned along the U.S.-Mexico border, from Tamaulipas to Baja California, hosting a multitude of U.S. companies that have successfully established operations.

Challenges in Establishing Operations

- Regulatory Environment Navigating Mexico's distinct legal and tax frameworks requires comprehensive understanding and compliance, particularly concerning business formation and operational regulations.

- Cultural and Language Differences Effective communication and integration necessitate overcoming language barriers and cultural differences to ensure seamless operations.

- Infrastructure Considerations While Mexico offers developed infrastructure, assessing specific regional capabilities is crucial to align with operational requirements.

Familiarize Yourself with the USMCA and the IMMEX

If you are planning on doing manufacturing in Mexico, you absolutely must familiarize yourself with two acronyms: USMCA & IMMEX.

According to Investopedia, The U.S. – Mexico – Canada Agreement (USMCA) is:

“..a trade deal between the three nations which was signed on November 30, 2018. The USMCA replaced the North American Free Trade Agreement (NAFTA), which had been in effect since January of 1994. Under the terms of NAFTA, tariffs on many goods passing between North America's three major economic powers were gradually phased out.

What is the significance of the USMCA when starting a manufacturing operation in Mexico?

The USMCA offers a modernized framework that facilitates smoother trade flows and increases market access across the region. With streamlined customs procedures, reduced tariffs, and enhanced intellectual property protections, businesses can benefit from a more favorable environment for cross-border manufacturing.

What is the significance of the IMMEX?

IMMEX, which stands for Industrial Promotion and Export Manufacturing Program (Programa de la Industria Manufacturera, Maquiladora y de Servicios de Exportación), holds significant importance when starting a manufacturing operation in Mexico. This program was established by the Mexican government to attract foreign investment, stimulate economic growth, and boost exports.

The IMMEX program offers a range of benefits and incentives to companies engaged in manufacturing activities that are intended for export. By participating in the program, businesses can take advantage of various advantages, including:

- Import and Export Facilitation: IMMEX enables companies to import raw materials, components, and equipment duty-free, as long as they are used in manufacturing products intended for export. This eliminates or reduces customs duties and allows for more cost-effective production processes.

- Value-Added Tax (VAT) Certification: Under the IMMEX program, companies can obtain VAT certification, which enables them to defer the payment of VAT on imported goods. This provides additional cash flow benefits for businesses.

- Simplified Administrative Processes: IMMEX streamlines administrative procedures, making it easier and faster for companies to set up and operate their manufacturing operations in Mexico. It simplifies customs processes, documentation requirements, and compliance procedures, reducing bureaucratic hurdles and saving valuable time.

- Flexibility and Cost Efficiency: The IMMEX program allows for flexible production and inventory management. Companies can benefit from the temporary importation of goods, enabling them to respond quickly to market demands, reduce inventory costs, and optimize their supply chains.

- Job Creation and Training: The program encourages companies to invest in the development of skilled labor by providing incentives for job creation and training programs. This helps enhance the local workforce and contributes to the growth of the manufacturing sector.

Overall, the IMMEX program plays a crucial role in attracting foreign investment and promoting manufacturing activities in Mexico. Its benefits and incentives make Mexico an attractive destination for companies looking to start or expand their manufacturing operations, offering a competitive edge in terms of cost-efficiency, streamlined processes, and access to global markets.

What Companies Often Overlook Starting a Manufacturing Operation in Mexico

When embarking on manufacturing operations in Mexico, it's crucial to pay attention to important details that may sometimes be overlooked. While these items may not be deemed essential for starting operations, neglecting them can hinder your progress. Here are some of the key aspects that should be addressed before launching your manufacturing endeavors:

Certificate of Origin: It is crucial that anything entering Mexico be accompanied by the appropriate documentation, including a certificate of origin. According to the International Chamber of Commerce:

A Certificate of Origin (CO) is an important international trade document that certifies that goods in a particular export shipment are wholly obtained, produced, manufactured or processed in a particular country. They declare the ‘nationality’ of the product and also serve as a declaration by the exporter to satisfy customs or trade requirements

HTS Code: One of the most important things to do is to get an HTS code for your product. HTS stands for Harmonized Tariff Schedule. You can find the HTS code for your product on the U.S. International Trade Commision website.

There are many reasons why HTS codes are important. Depending on the source of the raw material, the HTS code can indicate whether your finished product is subject to duties upon return to the U.S. By doing so, you will be able to make necessary changes so that everything is USMCA compliant, and therefore will not need to pay duties.

Understanding Tariff Shifts: Tariff shifts can be very complex, so having a general understanding of them is essential. A tariff shift can have a significant impact on the amount of duties a product must pay.

According to the International Trade Administration, under the USMCA, one of the ways you might qualify your product under Rules of Origin is by tariff shift.

Tariff shifting allows you to qualify your product under the Rules of Origin for USMCA and pay less on import duties. When non-originating components undergo a significant transformation, such as being combined together to make a new product, they are given a preferential tariff under the USMCA.

Avoiding Supply Chain Problems with CTPAT: Customs Trade Partnership Against Terrorism (CTPAT), an initiative of CBP Office of Field Operations, ensures that trade partners receive preferential treatment in foreign countries only if they are certified. According to Security magazine:

All companies must go through an extensive supply chain security audit and process to eventually get this certification by the government and ultimately speed up their way through security checkpoints, including ports of entries. For companies manufacturing and shipping from Mexico and Canada, it is of particular importance since it can be the difference between longer wait times at the border to cross merchandise. Having a certification allows for expedited treatment through segmented traffic lanes and decreased secondary inspections at those points of entry.

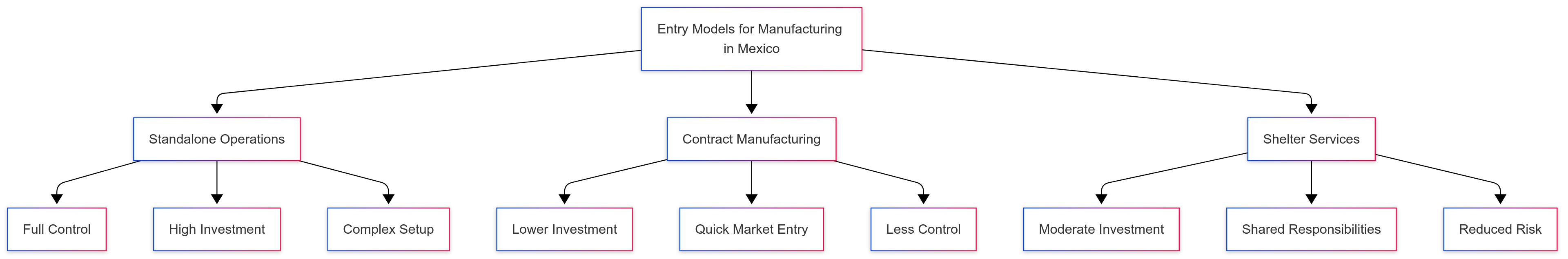

Strategies for Initiating Manufacturing in Mexico

Companies have several pathways to establish manufacturing operations in Mexico, each with distinct advantages and considerations:

1. Standalone Operations

This approach involves creating an independent entity within Mexico, granting complete control over all aspects of the business, including hiring, operations, and compliance. While offering autonomy, this model demands substantial investment and a deep understanding of local legal and regulatory landscapes. Large corporations with extensive resources often favor this route.

2. Contract Manufacturing

Engaging with a Mexican contract manufacturer allows companies to outsource production processes. This model is cost-effective and expedites market entry but may involve relinquishing some control over production quality and timelines. Additionally, sharing proprietary information with third parties can pose intellectual property risks.

3. Shelter Services

Partnering with a shelter company enables foreign manufacturers to operate under the shelter's existing legal framework, simplifying the establishment process. The shelter company manages administrative tasks, compliance, and legal responsibilities, allowing the foreign company to focus on manufacturing operations. This model reduces risk and accelerates setup times, making it a popular choice for companies seeking a balance between control and operational ease.

Comparative Analysis of Entry Models

To assist in decision-making, the following diagram illustrates the key characteristics of each entry model:

Starting a Manufacturing Operation in Mexico is Easier with a Nearshore Manufacturing Partner Get Consultant Help

If the prospect of handling all these tasks seems overwhelming, you may want to consider enlisting the services of a consulting firm that specializes in facilitating manufacturing setups in Mexico. Given the intricacies of Mexican government regulations, partnering with a shelter manufacturing expert can provide invaluable guidance and support in navigating the complexities of establishing and launching your business operations smoothly.

It may be more expensive to work with a shelter manufacturing partner, but there is no doubt that they will be able to assist you in cutting through the red tape and get production up and running more quickly. For example, certifications for CTPAT and IMMEX can take up to 6-12 months. However, if you choose a shelter manufacturer that is already CTPAT and IMMEX compliant, you will not have to worry about obtaining these certifications since the manufacturer will represent you in the process.

Navigating the process of manufacturing in Mexico may initially appear complex, but with a well-designed strategy, thorough research, and the guidance of a manufacturing partner, the journey can be greatly simplified. By dedicating time to familiarize yourself with both Mexican regulations and laws, as well as those of the United States, while understanding customs and best practices, you can steer clear of frustrations, save valuable time, and optimize your financial resources.

Conclusion: Starting a Manufacturing Operation in Mexico Has Become Increasingly Streamlined

Thanks to the US government's efforts in cutting red tape and fostering collaboration, starting a manufacturing operation in Mexico has become increasingly streamlined. The USMCA and cooperative initiatives have paved the way for entrepreneurs to seize opportunities in a dynamic market. By leveraging the advantages of reduced costs, increased market access, and a supportive business environment, businesses can unlock their potential for growth, innovation, and success.

FAQs on Starting a Manufacturing Operation in Mexico

Q:Is it beneficial to start a manufacturing operation in Mexico?

A; Absolutely! Starting a manufacturing operation in Mexico offers numerous advantages, including reduced costs, increased market access, and streamlined trade flows. It allows businesses to tap into a vibrant market and leverage strategic opportunities.

Q: How has the US government simplified the process for starting a manufacturing operation in Mexico?

A: The US government has taken proactive measures to reduce barriers and cut red tape. Through initiatives like the USMCA, regulatory harmonization, and infrastructure investments, they aim to facilitate cross-border trade and attract investment.

Q: What is the USMCA, and how does it benefit manufacturers?

A: The United States-Mexico-Canada Agreement (USMCA) is a trade deal that modernizes and replaces NAFTA. It offers streamlined customs procedures, reduced tariffs, and enhanced intellectual property protections, creating a more favorable environment for manufacturers.

Q: What kind of support can businesses expect when starting a manufacturing operation in Mexico?

A: Businesses can expect support in the form of shared best practices, regulatory transparency, and infrastructure improvements. The US government and Mexican counterparts are working together to create a seamless environment for entrepreneurs.

Q: How can infrastructure improvements in Mexico benefit manufacturing operations?

A: Infrastructure improvements in Mexico, such as transportation networks, logistics hubs, and digital connectivity, enhance supply chain efficiency.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.