Last Updated on September 4, 2024

Manufacturing has always been a crucial industry for any country's economic growth, creating jobs and providing products that meet the demands of consumers. However, with globalization and the rise of international trade, quality control has become increasingly important for manufacturing businesses to remain competitive. In this blog post, we will explore the importance of quality control in manufacturing and why Mexico is a good choice for superior quality manufactured products.

The Importance of Quality Control in Manufacturing

Quality control is the process of ensuring that a product meets certain standards and specifications. Quality control includes monitoring and testing products at different stages of production to ensure that they meet certain standards, from the sourcing of raw materials to the final packaging of the finished product.

Quality Control in Manufacturing Ensures Safety

The importance of quality control in manufacturing can be attributed to several factors. First of all, it ensures that products are safe for consumers to use. Manufacturers can take steps to mitigate potential safety hazards by testing products for quality before they are released to the market.

Creating a product is costly, time-consuming, and can be unsafe without controls in place. Additionally, if a company sends defective products out for purchase, it could be held liable for injuries or issues that arise from using its products. Quality control inspectors ensure that defective or unsafe products are identified, and the causes are corrected. - Investopedia

Quality Control Maintains Consistency

Secondly, quality control helps to maintain consistency in the production process. By monitoring the manufacturing process and testing products at different stages, manufacturers can identify and address any issues that may arise, ensuring that products are consistent in quality and meet the same standards every time.

Quality Control Keeps Customers Happy

Finally, quality control ensures customer satisfaction.

Manufacturers can build customer loyalty by producing high-quality products and ensuring that their customers are satisfied. According to Sweet Process:

If your products and services are of poor quality, you’ll spend more time and money reworking them, which eats into your profits in the long run. In addition, your customers won’t be satisfied with your products and will stop doing business with you. As word spreads about your products and services, your reputation will be affected. - Sweet Process

The Cost of Quality Control Neglect

Neglecting quality control can have severe consequences. A single defective product can lead to a massive recall, resulting in financial losses and a tarnished brand image. Moreover, it can also lead to legal battles, further exacerbating the damage. On the other hand, investing in quality control can save you from these headaches and ensure customer satisfaction.

Quality Assurance vs. Quality Control

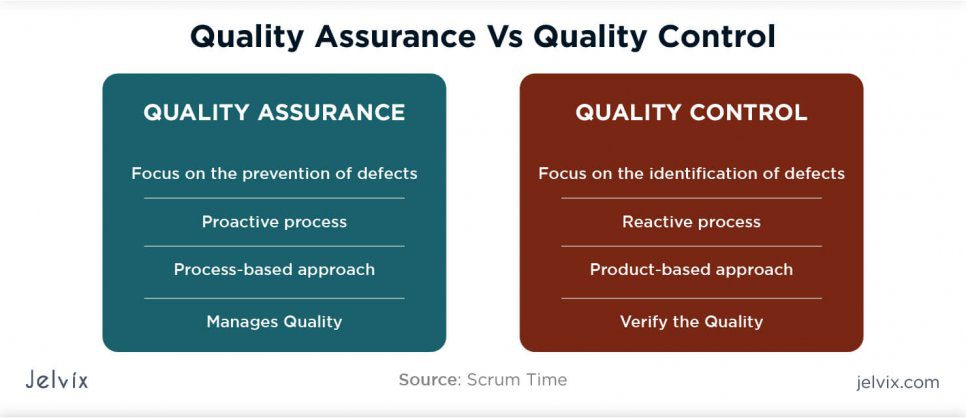

The terms Quality Assurance and Quality Control are often used interchangeably, but there are some differences between them. According to Jelvix, a quality assurance process focuses on the methods that are selected for development and testing to ensure that the team is following the right approach. A quality control process focuses on the end product, its functionality, interface, and performance.

Why Mexico is a Good Choice for Superior Quality Manufactured Products

Mexico has emerged as a global manufacturing hub in recent years, with a strong emphasis on quality control. Several factors contribute to Mexico's reputation for producing high-quality manufactured products.

Highly Skilled Workforce

Firstly, Mexico has a highly skilled workforce. The country has a large pool of well-educated and skilled workers, particularly in the manufacturing industry. Mexico has invested heavily in education and training programs to ensure that its workforce has the skills and knowledge necessary to compete in the global market.

Transparent Supply Chains

Secondly, Mexico has a well-developed and transparent supply chain infrastructure. The country has established a robust supply chain network that allows manufacturers to source high-quality raw materials and components at competitive prices. This supply chain infrastructure helps to ensure that manufacturers can produce high-quality products at a lower cost.

Strong Commitment to Quality Control

Thirdly, Mexico has a strong commitment to quality control. The Mexican government has implemented strict regulations and standards for manufacturing, ensuring that products produced in Mexico meet the highest quality standards. Mexico is committed more than ever to the highest standards of quality and quality control for its products due to new standards in Mexican law and Mexico's participation in the United States-Mexico-Canada Agreement (USMCA).

Mexico’s new Quality Infrastructure Law (QIL), was published in the Mexican Official Gazette on July 1, 2020 and entered into force on August 31, 2020. The QIL replaces the Federal Law on Metrology and Standardization (LFMN). The Mexican Government has stated it is based on the principles of integrity, transparency, efficiency, international best practices, quality, and traceability. - International Trade Association

Quality Control Operations in Mexico

In addition to government regulations, Mexican manufacturers are committed to quality control and invest in advanced testing and monitoring technologies to ensure that their products are of the highest quality. Many manufacturers in Mexico have implemented ISO 9001 quality management systems, which help to ensure consistent quality in their products and processes.

In 2019 Mexico was registered with 7, 741 ISO 9001 certificates and Canada accumulated 4, 557. Compared to 2018 there was an increase of 1, 206 certificates in Mexico, if we follow the trajectory of the trends in Mexico, we could estimate that the increase will continue due to the economic activities in conjunction with Canada and the United States. - Q Alliance

There is a strong commitment to quality control in Mexico's textile and apparel industries, for example. In order to ensure that the products meet or exceed customer expectations, the country has established strict quality standards, which manufacturers are required to adhere to. A quality control system is used by Mexican manufacturers to monitor the production process, identify defects, and ensure that the products are defect-free.

The reaction of Mexican factories to receiving substandard components or materials is typically to stop operations and consult with the customer (i.e. Zero Defects culture). There is no “buyer beware” attitude. There are quality issues, for certain, but prompt and full disclosure is normal. There is also the added convenience of being able to travel to Mexico and back in two days to personally observe the issues and to problem solve in the immediate term.

For those companies which require third-party certifications, these are readily available throughout Mexico and include the same independent laboratories employed in China; ISO is heavily employed throughout Mexico. - Shoreview Advisors

Conclusion: Quality Control is Essential

In today's global marketplace, quality control is essential for any manufacturing business. Having a strong focus on quality control and an infrastructure that supports the production of high-quality products, Mexico has emerged as a leader in manufacturing. Business can benefit from Mexico's skilled workforce, robust supply chain infrastructure, and commitment to quality control by choosing Mexico for manufacturing. This ensures that their products are of the highest quality and meet customers' requirements.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.