Last Updated on June 9, 2024

Increasing manufacturing capacity is crucial for companies seeking to meet growing customer demands and gain a competitive advantage in today's rapidly evolving business environment. The expansion of in-house manufacturing facilities can, however, be a complex and costly process. This is where outsourcing becomes invaluable. By leveraging outsourcing, businesses can access the expertise and resources of external partners, enabling them to scale up their manufacturing capacities in a cost-effective and efficient manner. This article discusses the benefits, challenges, and best practices of outsourcing manufacturing operations.

Understanding the Power of Outsourcing

Outsourcing refers to the practice of entrusting specific tasks or processes to external vendors or partners who specialize in those areas. When it comes to manufacturing, outsourcing involves delegating certain production processes to third-party manufacturers. This strategic move allows businesses to focus on their core competencies while benefiting from the expertise and resources of their outsourcing partners.

The Benefits of Outsourcing for Scaling Up

- Cost Savings: Outsourcing manufacturing processes can lead to significant cost savings for businesses. By partnering with external manufacturers, companies can avoid heavy capital investments in additional equipment, facilities, and specialized personnel.

- Access to Expertise: Outsourcing opens the doors to a vast pool of specialized knowledge and expertise. External partners often have extensive experience in their respective fields, enabling them to produce high-quality goods efficiently.

- Flexibility and Scalability: Outsourcing provides businesses with the flexibility to scale up or down their production capacities quickly and adapt to changing market demands. This agility is crucial in today's dynamic business environment.

Today’s knowledge and service-based economy offers innumerable opportunities for well-run companies to increase profits through strategic outsourcing.

MIT Sloan

Challenges in Outsourcing Manufacturing

While outsourcing offers numerous benefits, it also presents certain challenges that need to be carefully addressed.

- Quality Control: Maintaining consistent quality across outsourced production can be a challenge. Businesses must establish clear quality standards, implement robust monitoring processes, and maintain open lines of communication with their outsourcing partners.

- Intellectual Property Protection: Protecting intellectual property (IP) is a critical concern when outsourcing manufacturing processes. Companies must ensure that proper contracts and confidentiality agreements are in place to safeguard their proprietary information.

- Communication and Coordination: Effective communication and coordination between the business and its outsourcing partners are essential. Clear communication channels, regular meetings, and defined expectations help build strong relationships and minimize misunderstandings.

Quality isn’t just about profits and loss or beating out a competitor. It’s about safety, delivering on a promise and meeting the very basics of customer expectations. But, by meeting quality standards, companies often reap better profits and reduce losses. Those that exceed quality standards stand out above their competitors and further their potential for profit and consumer loyalty. Therein rests the benefit of quality standards.

Understanding the Importance of Quality Standards

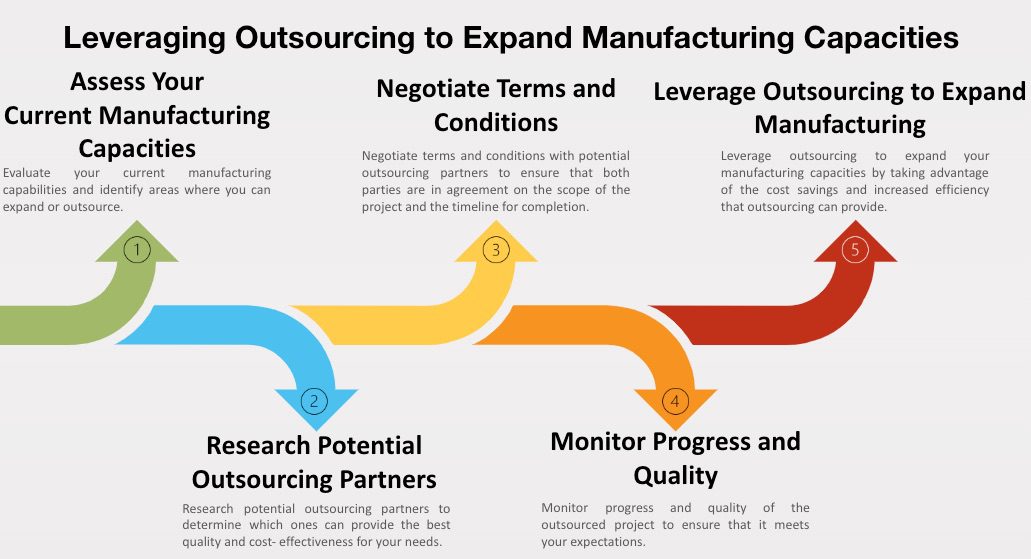

Best Practices for Leveraging Outsourcing

- Strategic Partner Selection: Choosing the right outsourcing partner is vital. It is crucial to assess their expertise, experience, financial stability, production capabilities, and reputation before making a decision.

- Transparent Collaboration: Open and transparent collaboration with outsourcing partners is key. Clearly defining project requirements, timelines, and expectations helps ensure a smooth and successful partnership.

- Robust Contracts and Agreements: Comprehensive contracts and agreements protect the interests of both parties. These documents should outline deliverables, quality standards, IP protection, liability, termination clauses, and any other relevant terms and conditions.

- Regular Performance Evaluation: Regularly assessing the performance of outsourcing partners is essential. This evaluation helps identify areas for improvement, address any issues promptly, and maintain a high level of quality throughout the partnership.

Just as you'd ask for job references for potential hires, ask for an outsourcing vendor's references. Request customer feedback from past and present clients regarding the scope and quality of services they received. Ask about the challenges they experienced in the partnership.

7 Smart Tips for Evaluating Your Outsourcing Partner

Outsourcing to Mexico Is a Prudent Choice

Outsourcing manufacturing to Mexico can be a smart business decision for several compelling reasons. Firstly, Mexico offers a strategic geographical advantage, being in close proximity to the United States, a significant market for many industries. This proximity translates into reduced transportation costs and shorter lead times, enabling companies to respond swiftly to market demands. Secondly, Mexico boasts a skilled and cost-effective labor force, making production costs more competitive compared to some other regions. The country has also established a stable political and economic environment, providing a sense of security for foreign investors. Moreover, Mexico has a network of free trade agreements with numerous countries, facilitating easy access to global markets. By leveraging these benefits, businesses can enhance their efficiency, increase profit margins, and gain a competitive edge, making outsourcing to Mexico a prudent choice.

Conclusion

Outsourcing manufacturing processes can be a game-changer for businesses looking to scale up their production capacities. It offers cost savings, access to expertise, and flexibility, enabling companies to meet increasing market demands effectively. However, to reap the benefits of outsourcing, businesses must address challenges related to quality control, IP protection, and communication. By following best practices such as strategic partner selection, transparent collaboration, and robust contracts, companies can forge successful outsourcing partnerships and achieve their scalability goals.

FAQs for Leveraging Outsourcing to Expand Manufacturing Capacities

Q1: How can outsourcing help businesses expand their manufacturing capacities?

Outsourcing allows businesses to tap into external expertise and resources, enabling them to scale up their manufacturing capacities efficiently and cost-effectively. By partnering with specialized manufacturers, companies can focus on their core competencies while benefiting from the capabilities of their outsourcing partners.

Q2: What are the potential challenges of outsourcing manufacturing processes? Some challenges include maintaining quality control, protecting intellectual property, and ensuring effective communication and coordination with outsourcing partners. These challenges can be addressed through clear expectations, robust contracts, and regular performance evaluations.

Q3: How can businesses select the right outsourcing partner?

Selecting the right outsourcing partner involves assessing their expertise, experience, financial stability, production capabilities, and reputation. It is important to conduct thorough research, seek recommendations, and evaluate multiple potential partners before making a decision.

Q4: How can businesses ensure quality control when outsourcing manufacturing?

Businesses can ensure quality control by establishing clear quality standards, implementing robust monitoring processes, and maintaining open communication with their outsourcing partners. Regular audits and performance evaluations also help maintain consistent quality.

Q5: What steps can businesses take to protect their intellectual property when outsourcing?

To protect intellectual property, businesses should have proper contracts and confidentiality agreements in place with their outsourcing partners. These agreements should outline the terms of IP protection, data security measures, and liability in case of any breaches. Regular audits and trust-building measures can also help mitigate risks.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into outsourcing manufacturing in Mexico with our curated collection of related blog posts.

- Why Mexico Isn’t a Perfect Manufacturing Solution (and What That Really Means)

- Mexico Rewards Manufacturing Companies That Commit: Here’s Why

- Smart Moves: Strategies for Manufacturing in Mexico That Actually Work

- Bill of Lading Explained: Essential Guide to Types, Terms, and How It Impacts Your Manufacturing Operations in Mexico

- Americans Say They Want More U.S. Factory Jobs—So Why Don’t They Want to Work in Them?

- Top 10 Well-Known American Companies in Mexico—Should You Be Next?

- Offshoring and Outsourcing: Strategic Global Business Solutions

- 5 Essential Manufacturing Operations Strategies to Thrive Amid Uncertainty in 2025

- Shaping the Future: Innovations in Sustainable Manufacturing in Mexico

- Flexible, Responsive Production: How Mexico Enables Agile Manufacturing to Meet Dynamic Demand