Last Updated on July 5, 2023

When it comes to manufacturing in Mexico, selecting the right site is crucial for success. Site selection in Mexico should take into account various factors such as logistics, proximity to the US border, ease of shipping, and ease of sourcing suppliers. In this blog post, we will explore why choosing a site closer to the US border is important, how easy it is to ship to the US from Mexico, why choosing to manufacture in Mexico is a smart business decision, and why partnering with a nearshore manufacturing partner like NovaLink can be a better option than starting a factory from scratch.

Site Selection in Mexico: A Guide to Successfully Choosing a Manufacturing Site Share on XWhy Choose a Site Closer to the US Border?

One of the primary reasons for choosing a site closer to the US border is logistics. Mexico has a well-developed transportation infrastructure that facilitates the shipment of goods to the US. However, the closer your manufacturing site is to the border, the lower your transportation costs will be. Cities which are close to or right on the border to the U.S., such as the manufacturing border city Matamoros where NovaLink’s manufacturing plants are located, are generally preferable to companies who will be shipping a large amount of finished manufactured goods on a regular basis.

Another benefit of being close to the border is faster delivery times. Shipping from Mexico to the US can take anywhere from a few hours to a few days depending on the distance and mode of transportation. Being closer to the border can significantly reduce the delivery time, allowing you to meet your customers' expectations and stay competitive in the market.

Ease of Shipping to the US

Mexico has several ports on the Pacific and Gulf coasts that connect to the US. The ports of Tijuana, Ensenada, and Mexicali are located near the US-Mexico border and offer easy access to the West Coast of the US. The ports of Veracruz, Altamira, and Tampico are located on the Gulf Coast and offer easy access to the East Coast of the US.

In addition to sea transportation, Mexico also has an extensive road network that connects to the US. The most popular border crossing is at Laredo, Texas, which connects to the Mexican city of Nuevo Laredo. Other popular crossings include Brownsville, Texas, which connects to the Mexican city of Matamoros, and San Diego, California, which connects to the Mexican city of Tijuana. According to ProLogis:

Few people realize how much progress Mexico has made in expanding and modernizing its interstate highway system. And fewer still are aware of how much difference these infrastructure improvements will make to Mexico’s economy. When completed, this new highway network will facilitate the easier, faster and safer movement of goods and people throughout the country. Mexican manufacturing will then be able to adopt the lean and just-in-time practices that have become standard elsewhere in the world.

Mexico also has a well-developed rail network that connects to the US. The major railroads that operate in Mexico are Kansas City Southern de Mexico, Ferromex, and Ferrosur. These railroads offer connections to major US railroads, making it easier to transport goods between the two countries.

Ease of Sourcing Suppliers

Mexico has a diversified economy with a robust manufacturing sector that includes automotive, aerospace, electronics, and medical devices. This means that there are many suppliers in Mexico that can provide the raw materials, components, and services you need to manufacture your products.

Sourcing suppliers in Mexico is relatively easy, especially if you work with a local partner like NovaLink. Local partners have established relationships with suppliers and can help you find the right supplier for your needs. They can also help you negotiate prices and manage the supplier relationship.

Choosing to Manufacture in Mexico: A Good Business Decision

Choosing to manufacture in Mexico is a good business decision for several reasons. First, Mexico has a large, young, and skilled workforce. The country has a population of over 130 million people, and more than half of them are under the age of 30. This means that there is a large pool of potential employees who are eager to work.

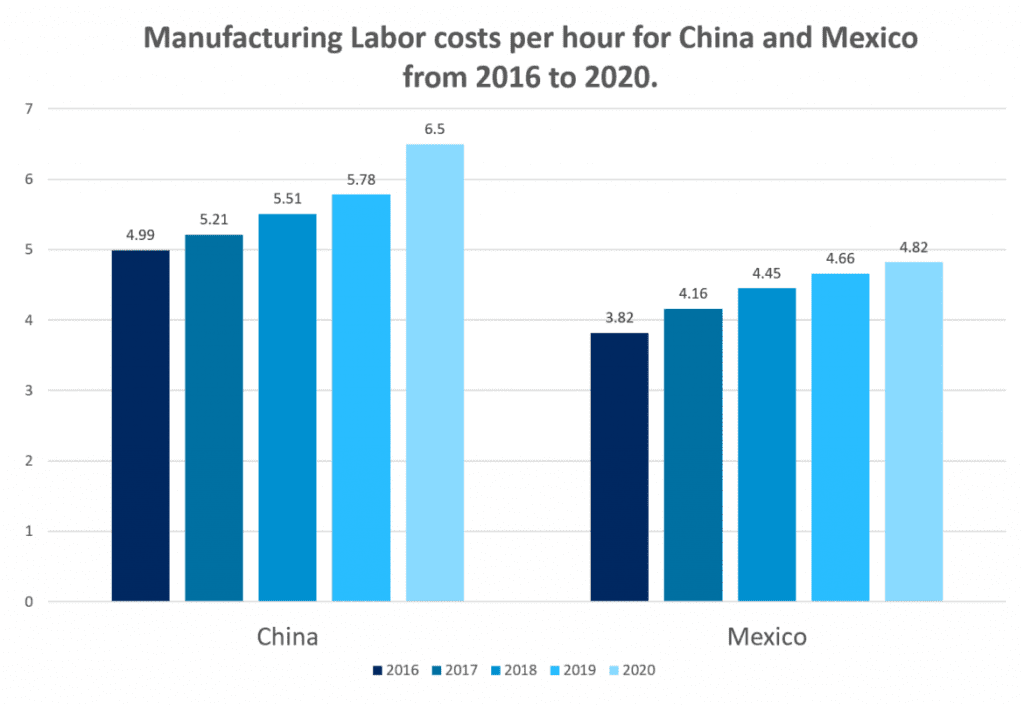

Second, labor costs in Mexico are lower than in the US. According to the National Bureau of Statistics and Geography (INEGI), the average daily wage in Mexico in 2020 was MXN 426. ($21.30 USD). This is significantly lower than the minimum wage in the US, which is $7.25 USD per hour. Lower labor costs in Mexico can translate into significant savings for manufacturers.

According to the National Bureau of Statistics and Geography (INEGI), the average daily wage in Mexico in 2020 was MXN 426. ($21.30 USD). Share on X

Third, Mexico has a stable political and economic environment. The country has a democratically elected government and has implemented economic reforms that have made it easier for foreign companies to do business in Mexico. In addition, Mexico has signed several free trade agreements with other countries, including the US, Canada, and the European Union. These agreements provide manufacturers with preferential access to these markets, making it easier for them to export their products.

Fourth, logistics play a vital role in site selection in Mexico. Mexico's diversified economy and skilled workforce provide companies with access to the raw materials, components, and services they need to manufacture their products. In addition, Mexico has implemented economic reforms that have made it easier for foreign companies to do business in the country. Mexico has also signed several free trade agreements with other countries, including the US, Canada, and the European Union. These agreements provide manufacturers with preferential access to these markets, making it easier for them to export their products.

Why Choose a Nearshore Manufacturing Partner Like NovaLink?

While choosing to manufacture in Mexico has many benefits, starting a factory from scratch can be a daunting task. Setting up a manufacturing site in a foreign country requires significant investment in time, money, and resources. There are many challenges involved in navigating the legal, regulatory, and cultural differences between the US and Mexico.

This is where a nearshore manufacturing partner like NovaLink can help. NovaLink is a US-owned and managed company that provides contract manufacturing services in Mexico. They have extensive experience working with US companies and understand the challenges involved in site selection in Mexico.

Partnering with NovaLink allows companies to benefit from the advantages of manufacturing in Mexico without the risks and costs associated with starting a factory from scratch. NovaLink takes care of all the logistics involved in setting up a manufacturing site, including site selection, legal compliance, hiring, training, and managing the workforce.

In addition, NovaLink can help companies navigate the supply chain in Mexico. They have established relationships with suppliers and can help companies source the raw materials, components, and services they need to manufacture their products.

Conclusion: Site Selection in Mexico Is a Critical Component of Manufacturing Success

Site selection should consider logistics, ease of shipping to the US, ease of sourcing suppliers, and why choosing to manufacture in Mexico is a good business decision. By choosing a site closer to the US border, companies can reduce transportation costs and delivery times. Mexico's well-developed transportation infrastructure, including ports, roads, and rail, make it easy to ship goods to the US. Mexico's diversified economy and skilled workforce provide companies with access to the raw materials, components, and services they need to manufacture their products.

Partnering with a nearshore manufacturing partner like NovaLink can further reduce the risks and costs associated with site selection in Mexico, making it easier for companies to succeed in the country's manufacturing sector.

FAQs: Site Selection in Mexico for Manufacturing

- Why is site selection important when considering manufacturing in Mexico? Site selection is crucial when considering manufacturing in Mexico because it directly impacts the success and efficiency of operations. Choosing the right location ensures access to skilled labor, transportation networks, infrastructure, supply chain integration, and proximity to target markets. Proper site selection minimizes logistical challenges, reduces costs, and enhances overall competitiveness.

- What factors should be considered when selecting a manufacturing site in Mexico?

Several factors should be considered when selecting a manufacturing site in Mexico, including:

a) Proximity to markets: Consider the location's accessibility to key markets, particularly if targeting the North American market, to reduce transportation costs and lead times.

b) Skilled labor availability: Evaluate the local labor force's skills and expertise in the desired industry to ensure access to the talent required for successful manufacturing operations.

c) Infrastructure and utilities: Assess the availability and quality of infrastructure, including transportation networks, reliable energy supply, water resources, and telecommunications.

d) Supplier and logistics ecosystem: Consider the proximity to suppliers, existing logistics networks, and the presence of industrial parks or clusters that can facilitate supply chain integration.

e) Business environment: Evaluate the local business environment, including regulatory frameworks, tax incentives, government support, and legal considerations, to ensure a favorable and stable operating environment.

- How can companies assess the availability of skilled labor in a potential manufacturing site in Mexico?

Companies can assess the availability of skilled labor in a potential manufacturing site in Mexico through various methods, such as:

a) Workforce analysis: Conduct a comprehensive analysis of the local labor market, including demographics, education levels, technical training programs, and relevant industry experience.

b) Collaboration with local organizations: Engage with local universities, technical schools, and industry associations to understand the availability of skilled labor and potential partnerships for talent development.

c) Labor market research: Utilize labor market research reports and data to assess the supply and demand dynamics of specific skill sets in the desired location.

d) Site visits and interviews: Visit the potential manufacturing site and conduct interviews with local labor providers, recruitment agencies, and potential employees to gauge the availability and quality of the labor pool.

- Are there any incentives or government support available for manufacturing site selection in Mexico?

Yes, Mexico offers various incentives and government support programs for manufacturing site selection, including:

a) IMMEX program: The IMMEX program provides tax benefits, duty exemptions, and streamlined customs processes for companies engaged in manufacturing, maquiladora, or export activities.

b) Special Economic Zones (SEZs): SEZs offer additional tax incentives, simplified administrative procedures, and infrastructure advantages to promote investment and manufacturing activities in designated areas.

c) Industry-specific incentives: Certain industries, such as automotive and aerospace, may benefit from sector-specific incentives and support programs provided by the Mexican government.

d) Government investment promotion agencies: Government agencies like ProMéxico and state-level investment promotion agencies provide assistance, guidance, and information on available incentives and support for companies considering manufacturing in Mexico.

- What role does due diligence play in the site selection process for manufacturing in Mexico?

Due diligence plays a crucial role in the site selection process for manufacturing in Mexico. It involves conducting thorough research, site visits, and assessments to gather relevant information about potential locations. Due diligence helps mitigate risks, uncover any hidden challenges or limitations, verify infrastructure capabilities, assess regulatory compliance, and ensure that the chosen site aligns with the company's objectives and requirements. It is essential for making informed decisions and minimizing potential issues during and after site selection.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.