Last Updated on October 16, 2024

Mexico's manufacturing industry has experienced significant growth in recent years, helped by International companies manufacturing in Mexico, specifically the United States. This boom in manufacturing has transformed Mexico into a major player in the global economy, with its close proximity to the United States and favorable trade agreements making it an attractive location for businesses looking to expand their operations.

In this blog post, we will take a closer look at international companies manufacturing in Mexico, exploring the benefits and challenges they face, and highlighting some of the most successful companies operating in the country. Whether you are a business owner looking to expand into Mexico or simply interested in the global economy, this post will provide valuable insights into one of the most exciting developments in the manufacturing industry today.

Benefits of International Companies Manufacturing in Mexico

International companies manufacturing in Mexico enjoy several benefits that make the country an attractive destination for their operations. The following are some of the main advantages:

- Access to a skilled workforce: Mexico has a large and well-educated workforce, with many workers possessing technical skills and experience in the manufacturing sector. This makes it easier for international companies to find qualified workers and reduce the time and cost associated with training.

- Lower labor costs compared to developed countries: The cost of labor in Mexico is significantly lower than in developed countries such as the United States, Canada, and many European countries. This allows companies to manufacture goods at a lower cost and increase their profit margins.

- Proximity to the United States market: Mexico's location makes it an ideal destination for companies looking to export their products to the United States market. With a shared border and close proximity to major U.S. cities, international companies can reduce transportation costs and improve supply chain efficiency.

- Government Incentives: The Mexican government offers various incentives, such as tax breaks and subsidies, to attract foreign investment.

- Favorable trade agreements: Mexico has several free trade agreements, including the United States-Mexico-Canada Agreement (USMCA) and the European Union-Mexico Free Trade Agreement, which provide international companies with preferential access to markets and reduce trade barriers.

- Infrastructure: Mexico has invested heavily in its infrastructure, including roads, ports, and airports, which makes it easier for companies to transport goods and access global markets.

Importance of International Companies in Mexico's Manufacturing Sector

As a result of international companies manufacturing in Mexico, thousands of Mexicans have the opportunity to work, contributing to the growth of the national labor force and reducing unemployment rates. New job opportunities have contributed to the improvement of the standard of living for many Mexican families.

ThoughtCo writes:

...more than one million Mexicans working in over 3,000 maquiladora manufacturing or export assembly plants in northern Mexico, producing parts and products for the United States and other nations.

Second, international companies manufacturing in Mexico bring with them the latest manufacturing technologies and best practices, which they share with their local employees. In addition to improving the quality and efficiency of Mexico's manufacturing sector, this technology transfer enhances its competitiveness in the global market. According to the International Trade Administration:

Mexico is among the five largest importers of advanced manufacturing technology globally. This sector has grown exponentially since 2020 as companies have started nearshoring to Mexico. Through their adoption of AM tools, Mexican manufacturers are investing in the technological advances needed to remain and stay ahead of the competition.

International companies in Mexico's manufacturing sector often export their products to other countries, thereby contributing to the country's export growth and balance of trade.

In 2023, the US traded $798bn with Mexico as the goods it bought from its southern neighbour surged past China and Canada. The boom around nearshoring – a catchy term that describes the movement of companies closer to their preferred market, in this case, the US – has helped drive Mexico into this position.

Politics and convenience drive Mexico to be US’s top trading partner

Furthermore, international companies manufacturing in Mexico in diverse industries such as automotive, aerospace, electronics, and medical devices contribute to Mexico's diversification, reducing its reliance on a few key industries. Increasing the Mexican economy diversification is essential to its long-term growth and sustainability.

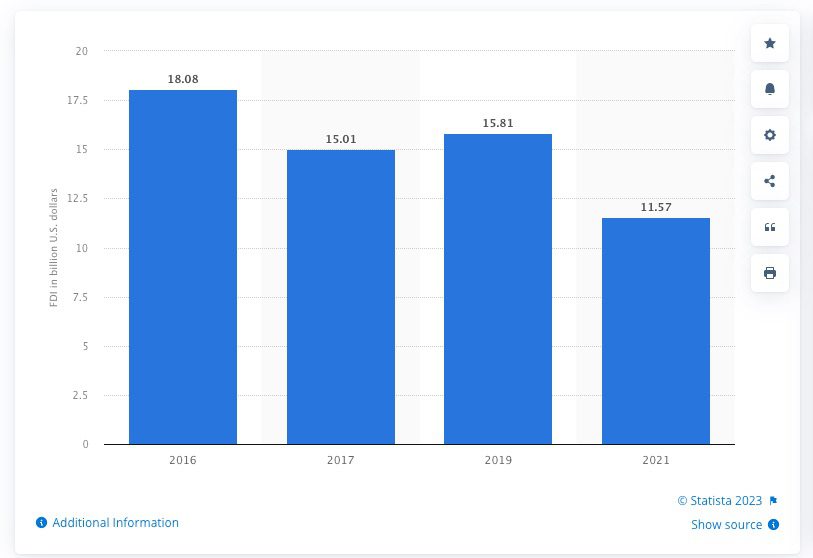

Last but not least, foreign companies investing in the country's manufacturing sector bring much-needed foreign direct investment, which is essential for Mexico's economic growth and development. Through this investment, new jobs are created, infrastructure is improved, and productivity is increased across a variety of industries. For its ease of doing business, Mexico ranks 54 of 192 analyzed countries globally and first across Latin America, according to the World Bank.

Source: Statista: Foreign direct investment (FDI) in the manufacturing sector in Mexico from 2016 to 2021

As a member of USMCA, OECD, G20, and the Pacific Alliance, Mexico is very well integrated into the world economic order, making it an attractive country for Foreign Direct Investment (FDI). Additionally, Mexico enjoys a strategic location, a big domestic market, a wide variety of natural resources, a relatively well-qualified workforce and diversified economy.

Santander: Mexico Foreign Investment

Mexico's manufacturing sector cannot be overstated without emphasizing the importance of international companies, as these companies contribute to the country's economic growth and diversification by introducing new technologies and providing employment opportunities.

International Companies Manufacturing in Mexico

There are many international companies that manufacture goods in Mexico. Here are some examples:

| Company | Products Manufactured |

|---|---|

| Ford | Cars and trucks for the Mexican and global markets |

| Samsung | Televisions and other electronic devices |

| Honeywell | Turbochargers, thermostats, and industrial safety equipment |

| Procter & Gamble | Laundry detergent, diapers, and shampoo |

| Foxconn | Components and finished products for companies such as Apple, HP, and Dell |

| Nestle | Coffee, chocolate, and infant formula |

| General Electric | Lighting, power systems, and medical equipment |

| Whirlpool | Refrigerators, washing machines, and other appliances |

Aerospace Manufacturers

When exploring the aerospace industry landscape in Mexico, several key manufacturers stand out for their significant contributions to the sector.

Leading Aerospace Manufacturers in Mexico

- Bombardier Inc.

Renowned for its innovation in aircraft design and production, this company has a substantial presence in the Mexican aerospace market. - EATON Corporation

Specializing in power management solutions, EATON plays a crucial role in supplying components essential for modern aerospace technology. - GKN Aerospace

This company excels in providing advanced aerospace components, consistently enhancing its manufacturing processes to meet industry demands. - Goodrich Corporation

Known for its broad spectrum of aerostructures and subsystems, Goodrich is integral to the aviation supply chain in Mexico. - Honeywell

With a focus on avionics and efficiency, Honeywell supports the aerospace industry by supplying state-of-the-art technology and systems. - ITR

This entity is pivotal in the maintenance and development of various aerospace components, contributing to the overall industry's growth. - MD Helicopters

Specializing in rotorcraft, MD Helicopters is part of Mexico's diverse aerospace manufacturing scene, significantly impacting the sector with its helicopter technology.

Growth in Mexico's Aerospace Industry

The aerospace sector in Mexico saw significant expansion between 2009 and 2017. During this period, the number of aerospace firms operating in the country nearly tripled. Starting with just 112 firms in 2009, the industry experienced a remarkable surge, growing to 330 firms by 2017.

This rapid expansion reflects the increasing attractiveness of Mexico as a hub for aerospace manufacturing and services. Such growth not only highlights the sector's vitality but also underscores Mexico's emergence as a key player in the global aerospace market.

The aerospace industry in Mexico has experienced remarkable growth over the last decade. Between 2013 and 2015, the industry saw an impressive annual export growth rate of 20%, which significantly contributed to the job market, creating around 63,000 new jobs in 2016 alone.

In terms of investment, foreign direct investment in the aerospace sector from 2007 to 2017 surpassed $6 billion, indicating robust international interest and confidence in the Mexican market. This influx of capital has been a crucial driver for expansion and development within the industry.

Furthermore, the number of aerospace companies has dramatically increased. In 2009, there were just 112 firms operating in the sector. By 2017, this figure had nearly tripled to 330 companies, demonstrating a substantial broadening of the industry's base and a significant boost in business activity and innovation.

Collectively, these factors underscore a strong upward trajectory for the aerospace industry in Mexico, characterized by rapid expansion, substantial investment, and significant job creation.

Mexican Government Initiatives to Boost the Aerospace Industry

The Mexican government has implemented a range of initiatives to bolster the aerospace sector. These efforts focus on incentives and educational programs designed to cultivate a skilled workforce.

1. Financial Incentives:

- The government offers tax breaks and subsidies to attract domestic and foreign investment into the aerospace industry. These financial incentives are tailored to support companies establishing operations or expanding their presence in Mexico.

2. Training Programs:

- A variety of training programs have been established to equip workers with the specialized skills required in the aerospace field. These programs often collaborate with established aerospace companies to ensure that the training is relevant and practical.

3. University Collaborations:

- Partnerships with universities are a key strategy. The government has worked with academic institutions to develop curricula specifically geared toward aerospace engineering and manufacturing. These programs aim to produce graduates ready to enter the aerospace workforce, with a deep understanding of the industry's unique demands.

Through these comprehensive efforts, the Mexican government aims to position the country as a global leader in aerospace manufacturing and innovation.

Automotive Manufacturers

In 2018, Mexico's automotive industry reached impressive export figures by producing 3.9 million vehicles. This production milestone placed Mexico as the fourth largest vehicle exporter globally. Moreover, the industry saw a robust 6% increase in its vehicle exports, highlighting its growing importance in the international automotive market. In Mexico, the auto manufacturing sector directly supports over 800,000 jobs.

Here are the ten biggest auto companies with manufacturing operations in Mexico:

- Toyota

- Volkswagen Group

- Daimler

- BMW

- Ford Motors

- Honda Motors

- General Motors

- Hyundai Motors

- Nissan Motors

- SAIC Motors

These automotive giants have chosen Mexico for its competitive advantages, fostering a robust automotive industry that contributes significantly to the country's economy. This blend of varied manufacturing capabilities underscores Mexico's role as a key player in global production networks.

These companies are not only prominent in Mexico but also globally recognized for their innovation and quality in aerospace manufacturing. Whether through the production of cutting-edge aircraft systems or the supply of critical components, they each play a vital role in the aerospace ecosystem.

Trade Agreements and the Automotive Industry in Mexico

The transformation of NAFTA into the USMCA has notably reshaped the auto manufacturing landscape in Mexico. One of the central changes is the increase in the Rule of Origin requirement. This change mandates that the percentage of auto parts made within North America rises from 62.5% to 75% by 2023. As a result, there is a push for more local content in vehicle production.

This revision incentivizes auto manufacturers to increase their operations within Mexico to meet the local content requirements, thereby boosting the country’s auto production capabilities. By doing so, manufacturers can align with the stricter guidelines, which ultimately bolster regional supply chains and enhance Mexico's role in the global automotive market.

Overall, the updated policies foster an environment conducive to growth in auto manufacturing, making the industry not only resilient but a significant contributor to Mexico's economic fabric. This strategic shift is part of why the sector is rapidly emerging as a leading force in manufacturing globally.

The updated North American Free Trade Agreement, now known as the United States-Mexico-Canada Agreement (USMCA), has brought about crucial regulations impacting Mexico's automotive industry. One of the key changes introduced is the adjustment in the Rule of Origin and local content production requirements. These new stipulations have raised the minimum regional value content from 62.5% to 75% by 2023 for vehicles to qualify for tariff-free trade across North America.

This increase is particularly significant for Mexico, as it encourages more domestic production and sourcing of automotive parts and components. By requiring a higher percentage of these components to be produced within North America, the USMCA aims to bolster local manufacturing economies, including Mexico's, which is a vital player in the industry's supply chain.

Furthermore, the changes incentivize auto manufacturers to invest in local facilities and workforce development within the region. This shift helps Mexico fortify its role within the automotive sector, enhancing its position as a key manufacturing hub. As a result, this supports increased job creation and technological advancements, ultimately contributing to the rapid growth and competitiveness of Mexico’s automotive industry on the global stage.

Medical Devices

When it comes to the prominent American producers in the medical device industry operating in Mexico, the landscape is impressive. Several major companies have set up their operations, taking advantage of the strategic location and skilled workforce.

Among these industry leaders, you'll find well-established names that range from manufacturers of medical supplies to advanced healthcare technologies. Key players include multinational corporations recognized for their innovative contributions to the medical field. Their presence in Mexico underscores the country's importance as a manufacturing hub for medical devices. Using Mexico as a base, these companies benefit from efficient production processes and improved distribution logistics to both North and South American markets. What percentage of medical devices manufactured in Mexico is sent to the United States or Canada? Over 90% of these devices are exported to these two markets.

In 2011, the estimated value of medical devices produced in Mexico was about $8.6 billion USD. Looking ahead, projections suggest that this figure will increase significantly, reaching over $15 billion USD by the following year.

What Types of Medical Devices are Manufactured in Mexico?

Mexico's vibrant manufacturing sector is a key player in the global medical device industry, producing a wide array of essential tools and equipment that impact healthcare worldwide.

Life-Enhancing Devices

Some of the significant items produced include various orthopedic aids like braces and wheelchairs, designed to improve mobility and support. Manufacturers are also involved in producing high-quality dentures and lenses, which play crucial roles in enhancing patients' daily lives.

Diagnostic and Monitoring Equipment

The country specializes in the production of diagnostic tools such as electronic thermometers and oximeters, essential for patient monitoring. Vital components for hemodialysis machines and infusion pumps are also crafted, ensuring seamless operation for critical healthcare procedures.

Treatment and Surgical Instruments

Manufacturers in Mexico contribute extensively to surgical care by supplying surgical kits and equipment. They also produce intricate items like pacemakers and stents, crucial for life-saving interventions.

Consumables and Accessories

Single-use medical supplies, from IV administration sets to urinary catheters, are also part of the production lineup. These are indispensable in maintaining sanitary conditions and ensuring safe medical procedures.

Other Medical Products

The production includes devices like nebulizers, essential for respiratory treatments, and x-ray film marking systems used in diagnostic imaging. These products underscore the diverse range of medical equipment engineered within the country.

In summary, Mexico's manufacturing sector is pivotal in delivering a broad spectrum of medical devices, contributing to both everyday healthcare needs and sophisticated medical treatments.

Future Outlook for International Companies Manufacturing in Mexico

Mexico has experienced significant growth as a manufacturing destination in recent years. It is not surprising that manufacturing companies are flocking to Mexico as the economy continues to grow and attract international businesses seeking new opportunities. There are a number of factors at play here, including lower wages than China and India, access to the United States market through USMCA, and over 40 million skilled workers.

Additionally, Mexico has made significant progress in improving its infrastructure; its ports have been upgraded with modern equipment, highways throughout the country are being constructed or renovated, and there is even talk of adding high-speed rail lines between major cities like Mexico City and Guadalajara.

Mexico’s manufacturing landscape presents a wealth of opportunities for businesses seeking to enhance their competitiveness in the global market. Whether it’s the allure of nearshoring, cost-effective labor, or strategic geographical location, Mexico continues to be a beacon for companies aiming to thrive in the dynamic world of manufacturing. Partnering with organizations like EDS International can further amplify the benefits, ensuring a smooth and successful journey into Mexico’s burgeoning manufacturing sector.

EDS International

Recommendations for Companies Considering Manufacturing in Mexico

If an international company is considering manufacturing in Mexico, here are some recommendations to keep in mind:

- Conduct a thorough analysis: Before making any decisions, it's important to conduct a comprehensive analysis of the costs, risks, and benefits of manufacturing in Mexico. This analysis should take into account factors such as labor costs, logistics, regulatory environment, and political stability.

- Choose the right location: Mexico has many different regions and cities, each with its own strengths and weaknesses. Companies should carefully consider the location of their manufacturing facility based on factors such as access to suppliers, transportation infrastructure, and availability of skilled labor.

- Partner with local experts: Working with local experts, such as lawyers, accountants, and consultants, can help companies navigate the regulatory and legal landscape in Mexico. These experts can also provide valuable insights into local market conditions and business practices.

- Invest in training and development: Mexico has a large and growing pool of skilled workers, but it's important to invest in training and development to ensure that employees have the skills and knowledge needed to operate manufacturing facilities effectively.

- Embrace sustainability: Companies should also consider the environmental and social impact of their manufacturing operations in Mexico. By implementing sustainable practices and investing in local communities, companies can build a positive reputation and enhance their long-term success.

Conclusion: International Companies Manufacturing in Mexico Is Expected to Continue to Increase in the Future

In conclusion, the rise of international companies manufacturing in Mexico is a trend that is set to continue in the coming years. With its favorable business environment, skilled workforce, and strategic location, Mexico has become an attractive destination for businesses looking to expand their operations.

The success stories of companies such as Ford, Samsung, and Whirlpool demonstrate that with the right strategy and approach, Mexico can provide significant benefits for businesses operating in the country. As the global economy continues to evolve, it will be fascinating to see how Mexico's role as a manufacturing hub develops, and what new opportunities and challenges emerge for international companies.

FAQs - Mexico's Manufacturing Boom: A Look at International Companies Manufacturing in Mexico

Q1: Why has Mexico become a hub for international companies for manufacturing?

A1: Mexico offers a combination of factors that make it an attractive destination for international manufacturing, including cost-effective labor, proximity to major markets, favorable trade agreements, and a skilled workforce.

Q2: Which industries have witnessed significant growth in Mexico's manufacturing sector?

A2: Mexico's manufacturing boom has been particularly pronounced in industries such as automotive, electronics, aerospace, medical devices, and consumer goods.

Q3: How do international companies benefit from manufacturing in Mexico?

A3: Manufacturing in Mexico allows international companies to reduce production costs, minimize logistical complexities, tap into skilled labor, and gain competitive advantages in the global market.

Q4: What role do trade agreements play in international companies' decision to manufacture in Mexico?

A4: Trade agreements like USMCA (United States-Mexico-Canada Agreement) provide international companies manufacturing in Mexico with tariff-free access to key markets, facilitating smoother cross-border trade.

Q5: How does manufacturing in Mexico impact the local economy and workforce?

A5: Manufacturing in Mexico contributes to job creation, skills development, and economic growth within the region. The influx of international companies also stimulates ancillary industries and infrastructure development.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.