Last Updated on July 16, 2025

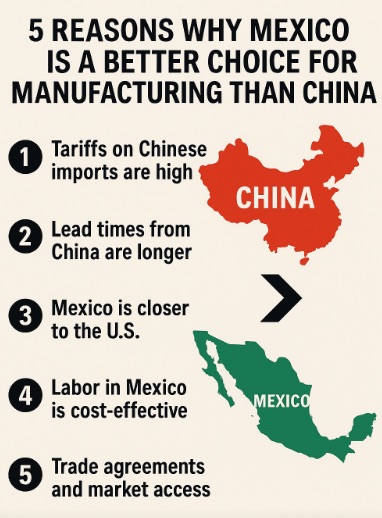

If you're still manufacturing in China, you’re likely feeling the squeeze. Between shipping delays, political tension, and—let’s be real—a gut-punch 55% tariff on certain Chinese imports, the math just isn’t adding up like it used to. That’s exactly why more companies are asking the big question: Why Mexico is a better choice for manufacturing right now?. Mexico is emerging as a compelling alternative to China as the manufacturing powerhouse of the world. Let’s break it down: why Mexico is a better choice for manufacturing than China.

1. Tariffs Are Taking a Bite Out of Your Bottom Line

Let’s start with the elephant in the room: the 55% tariff the U.S. slapped on some Chinese goods. That’s not a rounding error—it’s a direct hit to your margins.

You might be able to swallow that cost temporarily or pass it along to customers, but for how long? With the U.S.–China trade war ramping back up, this isn’t a one-off hiccup. It’s a pattern.

Meanwhile, under the USMCA (the updated NAFTA), goods produced in Mexico can often enter the U.S. duty-free. That means zero tariffs. Clean and simple.

Bottom line? If you're tired of tariff roulette, Mexico gives you more control—and fewer financial headaches.

2. You Can Actually Visit the Factory Without a 14-Hour Flight

Ever tried flying to your China plant for a quick audit (which many Chinese factories do not allow)? It's a 2-day ordeal. Add in jet lag, translation layers, and the cultural gap, and small miscommunications can become expensive mistakes.

Plus, if things go south, you don’t want to be 7,000 miles away.

Mexico's strategic location makes it an ideal manufacturing hub for companies targeting the North American market. With its shared borders with the United States and Canada, Mexico offers unparalleled proximity, enabling quicker and more efficient supply chain management.

Mexico? You can fly in from Texas, California, or the Midwest in a few hours. Some execs do it as a day trip. And with many shelter companies and suppliers fluent in both English and U.S. business culture, meetings just… make more sense.

Reduced transit times mean faster delivery to customers, resulting in enhanced customer satisfaction and increased competitiveness. Additionally, Mexico's robust transportation infrastructure, including an extensive network of highways, railways, and ports, facilitates seamless distribution of goods across the continent.

3. Labor in Mexico Isn’t Just Cheaper—It’s Skilled

Mexico boasts a highly skilled and productive workforce, renowned for its expertise in various industries, including automotive, aerospace, electronics, and medical devices. The country has made significant investments in vocational training and education programs to develop a skilled labor pool that meets the demands of modern manufacturing. Moreover, compared to China, Mexico offers competitive labor costs, ensuring cost-efficiency without compromising on quality. This combination of skilled labor and cost advantage makes Mexico an attractive choice for manufacturers seeking to optimize their production processes.

One of the main reasons manufacturers are reshoring or nearshoring their operations is the rising labor cost in traditional offshore destinations such as China. As wages continue to increase, the cost advantage of manufacturing in China has begun to diminish.

These increases have prompted many manufacturers to look at alternative locations where labor costs are lower but there is still access to a skilled workforce. Mexico fits that bill. With a large pool of highly skilled workers in engineering, IT, and manufacturing, many near-term problems caused by recent disruptions can be eliminated.

Is Mexico The New China? Re-shoring And Nearshoring To Adjust To Supply Chain Challenges

4. Lead Times from China Are Wildly Unpredictable

Imagine this: Your product leaves Shanghai on time, but then? Port congestion. Customs delays. Oh, and don’t forget that floating traffic jam off Long Beach. Suddenly, your 30-day lead time turns into 60.

Now picture the same product coming from northern Mexico. It hits the border in a day. A truck gets it across. You're holding it within the week.

Over the years, Mexico has developed a robust manufacturing infrastructure to support various industries. The country is home to numerous industrial parks and special economic zones, providing businesses with state-of-the-art facilities and logistical support.

These manufacturing clusters offer a range of advantages, including access to reliable utilities, advanced telecommunications, and comprehensive supply chain services. Furthermore, Mexico's close collaboration with key industries has fostered the development of specialized supplier networks, ensuring a seamless flow of components and raw materials for efficient production.

And let’s be honest: after COVID and the supply chain chaos that followed, who wants to roll the dice on trans-Pacific shipping again?

Shipments from China are taking longer due to port congestion, equipment shortages, customs delays, and global supply chain disruptions. - HongOcean

5. Mexico Opens More Doors Than You Think

Here’s something easy to overlook: Mexico isn’t just close—it’s connected. Thanks to the USMCA, products made in Mexico often move into the U.S. and Canada tariff-free. That’s a huge leg up if you're selling in North America.

But it doesn’t stop there.

The country is a signatory to the United States-Mexico-Canada Agreement (USMCA), ensuring preferential access to the lucrative North American market. Additionally, Mexico has a broad network of free trade agreements with countries around the world, granting businesses access to over 50 nations. These agreements eliminate or reduce import tariffs, making Mexican-manufactured products more competitive globally. By leveraging Mexico's trade partnerships, manufacturers can expand their customer base and tap into new market opportunities.

That means manufacturers in Mexico aren’t boxed in. They can reach Europe, South America, even parts of Asia without getting hammered by import duties.

In short? If you build in Mexico, you’re not just making things more affordably—you’re making it easier to sell them almost anywhere.

The Real Question Is: What Are You Still Waiting For?

Why Mexico is a better choice for manufacturing isn’t a theoretical question anymore—it’s a practical one. If you’re dealing with 55% tariffs, ballooning shipping costs, delayed inventory, or just the constant uncertainty of China, you’re not stuck.

Mexico is open, ready, and closer than you think—in every sense of the word.

And if you’re nervous about making the leap alone? That’s where nearshore partners like NovaLink come in. You don’t have to build from scratch. You just have to start the conversation.

FAQs

What types of products are best suited for manufacturing in Mexico?

Mexico excels in industries like automotive, aerospace, electronics, textiles, and medical devices. Anything requiring skilled labor and proximity to the U.S. is a great fit.

How does the USMCA benefit U.S. companies manufacturing in Mexico?

USMCA allows for tariff-free movement of goods between the U.S., Mexico, and Canada, provided certain content requirements are met—saving you significant costs compared to China.

Is labor in Mexico really more cost-effective than China?

Yes. While raw wage comparisons may seem close, the total cost of labor (including training, retention, and efficiency) is often lower in Mexico due to better stability and proximity.

What risks should I consider when shifting from China to Mexico?

Like any move, there are setup challenges—regulatory compliance, supplier vetting, etc. But with the right partner, these risks are manageable and far less volatile than navigating China’s trade restrictions.

Can I move part of my supply chain to Mexico, or does it have to be all or nothing?

Many companies start by relocating just part of their operations—like final assembly or packaging. Mexico is perfect for hybrid or phased approaches.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into manufacturing in Mexico vs. China with our curated collection of related blog posts.

- The Workforce in Mexico vs. China: Which is More Skilled and Cost-effective?

- Environmental Sustainability: Why Manufacturing in Mexico is More Responsible Than in China [2024]

- The Importance of Intellectual Property Protection in Mexico versus China [2024]

- The Pros and Cons of Outsourcing Manufacturing to Mexico vs. China [2025]

- Mexico’s Proximity Gives It the Edge Over China

- 5 Reasons Why Mexico is a Better Choice for Manufacturing Than China

- Benefits of Manufacturing in Mexico vs. China: Which Country Offers More Value for Your Business?

- The Impact of Trade Agreements on Manufacturing in Mexico and China

- Closeness Counts: Why Sourcing For Manufacturing in Mexico Trumps China for Business Success [2024]