Last Updated on July 30, 2025

Let’s be honest: the global supply chain has been under serious stress the last few years. Delays, container shortages, and skyrocketing freight costs have companies rethinking the “China-only” playbook. That’s why Mexico has become more than just a backup plan—it’s a better plan. Its close proximity to the US makes it a more attractive manufacturing destination than China for many companies looking for stability, lower costs, and faster delivery.

But why exactly does being close matter so much? Here’s the thing: time is money, and distance costs both.

The Big Win: Faster, Cheaper Shipping

Imagine your goods sitting on a container ship somewhere in the Pacific, waiting weeks to arrive at a US port. That’s the reality many companies face when manufacturing in China. In contrast, goods from Mexico can cross the border and arrive at your facility in days—sometimes even hours if you’re operating near the border.

Shorter shipping distances mean:

- Faster response to changing customer demand

- Lower freight costs (no $20,000 container bills)

- Less risk of port congestion or customs delays

With efficient supply chains, Mexican manufacturers can quickly reach their US-based customers, facilitating just-in-time delivery and reducing inventory costs. That speed makes a difference. Need to replenish inventory because of a surprise sales bump? If your products are stuck on a ship from Shanghai, you’re in trouble. If they’re in Matamoros or Monterrey, you’re in control.

Where Are Brownsville and Matamoros?

Brownsville, TX is located on the far-south border of Texas, and Matamoros, Tamaulipas, Mexico, is located just across the Mexican border, on the southern bank of the Rio Grande.

In Tamaulipas, the manufacturing industry is primary to the economy's health. Tamaulipas ranks fifth among the states with the fastest growth along Mexico's northern border.

Mexico’s Proximity: Flexibility You Can Feel

Proximity isn’t just about shipping—it’s about agility. When your manufacturing partner is a quick flight or even a short drive away, you can actually be present. You can visit factories, inspect production lines, and address issues before they snowball into disasters.

China, on the other hand, often means long flights, language barriers, and working across time zones. Simple questions can take days to resolve. With Mexico, you can collaborate in real time.

Unparalleled Market Access

Mexico has an unparalleled market access due to its proximity to the US market. Having a population of over 330 million, the United States offers a large market for manufacturers. In addition, this proximity allows for faster response times to market demands, reduced shipping costs, and just-in-time manufacturing models to be accommodated. Mexican manufacturers have easy access to the vast US market, which allows them to deliver their products to customers in a timely manner, resulting in higher customer satisfaction and increased sales.

Lower Costs Without Cutting Corners

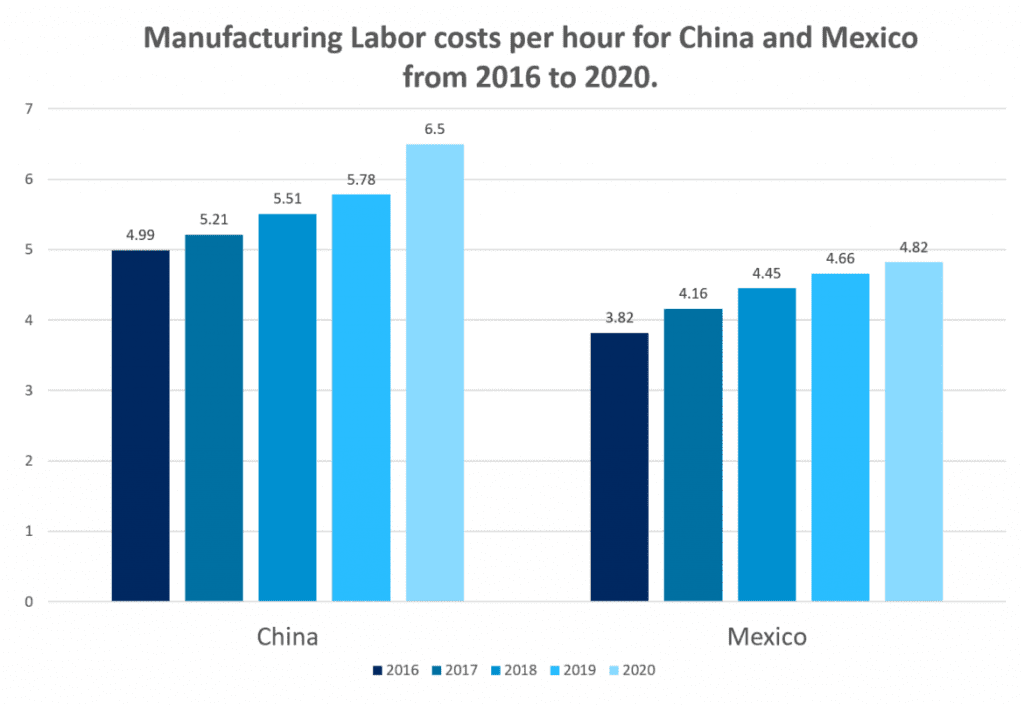

One of the biggest myths about moving away from China is that you’ll sacrifice cost competitiveness. That’s not the case with Mexico. While labor costs in China have risen dramatically over the last decade, Mexico continues to offer affordable, skilled labor. Mexico provides several cost advantages that make it a competitive alternative to China, which has been known for its low labor costs. The cost of labor in China has steadily increased over the past decade, narrowing the gap with Mexico.

And let’s not forget the savings from reduced shipping costs, smaller inventories (thanks to faster delivery), and fewer headaches from tariffs and trade disputes. These factors add up fast, often making Mexico the clear winner on total landed cost.

The USMCA Advantage

Trade agreements matter. The US-Mexico-Canada Agreement (USMCA) gives companies manufacturing in Mexico tariff advantages that simply don’t exist when sourcing from China. Components made in Mexico can qualify for duty-free treatment in the US, improving margins and making your supply chain more competitive.

You can think of USMCA as an insurance policy against unpredictable global trade policies. When geopolitical tensions flare—and they will—you’re less exposed.

Supply Chain Resilience in Real Life

Here’s the uncomfortable truth: the farther away your suppliers are, the more fragile your supply chain becomes. We saw this during the pandemic, when entire industries ground to a halt because factories in Asia were shut down.

Mexico’s closeness allows for just-in-time manufacturing that’s actually reliable. Instead of tying up cash in huge inventories “just in case,” you can maintain leaner operations and respond quickly to real-world demand.

Stronger Relationships, Better Results

t’s easier to build trust with partners you can see regularly. Mexico’s proximity makes it practical for leadership teams to stay connected with their manufacturing operations. Those frequent touchpoints lead to better quality control, faster problem-solving, and stronger relationships that benefit both sides.

Mexican workers have a deep understanding of the American market as a result of the close geographical and historical ties between the two countries. The majority of Mexican employees possess bilingual skills as well as a familiarity with American business practices, providing them with the ability to communicate and collaborate more effectively with their American counterparts. Compare that with the transactional nature of many overseas partnerships, where you might visit the factory once a year. In Mexico, you can be hands-on without disrupting your life—or your schedule.

Is It Always the Right Move?

Of course, there’s no one-size-fits-all solution. Some industries still rely heavily on China for specific components or materials. And shifting your operations isn’t without challenges—it takes planning and the right partners.

But if your goal is speed, control, and cost efficiency, Mexico is hard to beat. And with companies increasingly reshoring or nearshoring to stay competitive, waiting too long to make the move could put you behind the curve.

Conclusion: Mexico's Proximity to the United States Gives It a Competitive Edge

In conclusion, Mexico's proximity to the United States gives it a competitive edge over China as a manufacturing destination. The logistical advantage, cost efficiency, cultural compatibility, market access, political stability, and strong trade relations all contribute to its attractiveness. As more businesses recognize Mexico as a more attractive manufacturing destination than China, they will see the benefits of manufacturing in Mexico, as country continues to thrive as a key player in the global manufacturing landscape.

FAQs on Mexico’s Proximity

Q1: Is Mexico's manufacturing sector growing rapidly?

A: Yes, Mexico's manufacturing sector has experienced significant growth in recent years, attracting both domestic and foreign investments.

Q2: How does Mexico compare to China in terms of labor costs?

A: While China historically had lower labor costs, Mexico now offers competitive labor rates, narrowing the gap between the two countries.

Q3: Does the USMCA benefit manufacturers in Mexico?

A: Yes, the USMCA has eliminated tariffs between Mexico, the United States, and Canada, fostering a favorable trade environment for manufacturers in Mexico.

Q4: Are there any potential challenges in manufacturing in Mexico?

A: Like any manufacturing destination, there may be challenges such as navigating local regulations, ensuring supply chain resilience, and addressing specific industry needs.

Q5: Can manufacturers in Mexico easily reach customers in the United States?

A: Absolutely, Mexico's proximity to the US allows for swift transportation, ensuring manufacturers can quickly reach their US-based customers.

Q6: What’s the first step to moving production to Mexico?

A: Start with a feasibility assessment. Look at your product mix, shipping needs, and cost structure. Then consult with a nearshore manufacturing partner who can walk you through site selection, compliance, and setup.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into manufacturing in Mexico vs. China with our curated collection of related blog posts.

- The Workforce in Mexico vs. China: Which is More Skilled and Cost-effective?

- Environmental Sustainability: Why Manufacturing in Mexico is More Responsible Than in China [2024]

- The Importance of Intellectual Property Protection in Mexico versus China [2024]

- The Pros and Cons of Outsourcing Manufacturing to Mexico vs. China [2025]

- Mexico’s Proximity Gives It the Edge Over China

- 5 Reasons Why Mexico is a Better Choice for Manufacturing Than China

- Benefits of Manufacturing in Mexico vs. China: Which Country Offers More Value for Your Business?

- The Impact of Trade Agreements on Manufacturing in Mexico and China

- Closeness Counts: Why Sourcing For Manufacturing in Mexico Trumps China for Business Success [2024]