Last Updated on May 13, 2024

In today's global economy, efficiency is king. For US manufacturers, that often means rethinking traditional overseas production models. Enter nearshoring to Mexico. In recent years, US companies have been turning to Mexico for industrial manufacturing as a strategic move to streamline their production processes. This strategic shift is gaining serious momentum. It offers a wealth of advantages for companies seeking to streamline operations, reduce costs, and stay ahead of the curve. Let's delve into the reasons why American companies are increasingly turning south of the border to fuel their success.

The Rise of Nearshoring

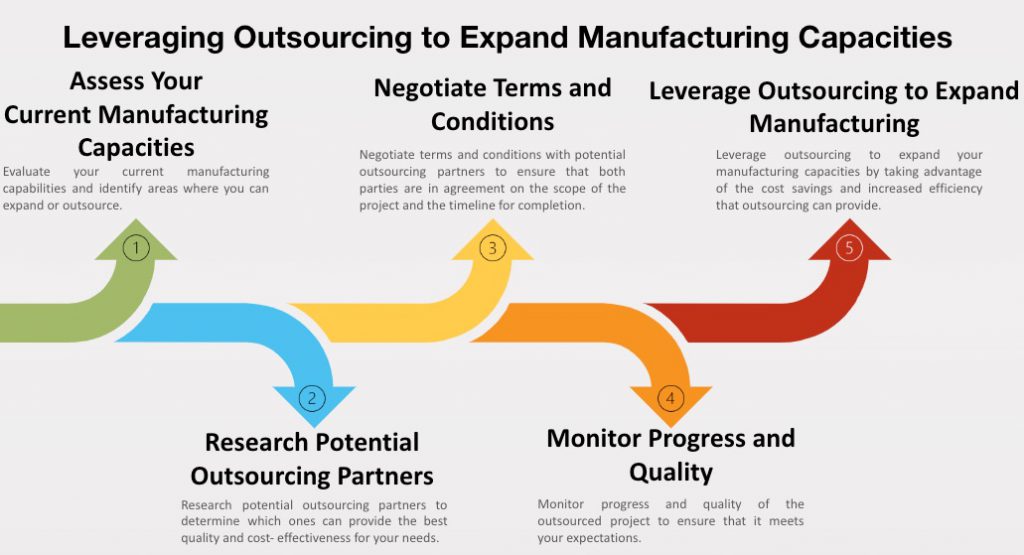

The rise of nearshoring to Mexico for US companies in industrial manufacturing can be attributed to several key benefits: by relocating their manufacturing operations to Mexico, companies can capitalize on the country's proximity, cost-effectiveness, and skilled workforce.

Proximity and Logistics

One of the primary advantages of nearshoring to Mexico is its proximity to the US. With shared borders and a short shipping distance, companies can significantly reduce transportation costs and lead times. This enables faster delivery of products, making it ideal for companies that require just-in-time inventory management. Mexico's modern ports and transportation infrastructure ensure efficient and reliable logistics.

Cost-Effective Production

Mexico offers a cost-effective industrial manufacturing solution, with labor costs significantly lower than in the US. Additionally, Mexico's government has implemented various incentives, such as tax breaks and subsidies, to attract foreign investment. This enables companies to allocate resources more efficiently, reducing production costs without compromising quality.

Skilled Workforce and Quality Control

Mexico has invested heavily in education and training programs, resulting in a skilled and dedicated workforce. Mexico manufacturing companies have implemented robust quality control measures, ensuring their products meet international standards. In fact, Mexico is home to numerous ISO-certified facilities, demonstrating its commitment to quality and excellence.

Mexico is committed to invest in education and workforce development due to its geographical position, political and economic stability, and the different trade agreements signed with other countries, including the United States-Mexico-Canada Agreement (USMCA), to generate professional and specialized profiles mainly in STEM disciplines.

International Trade Administration

Flexibility and Scalability

Nearshoring to Mexico allows companies to respond quickly to changing market demands. With flexible and scalable production capacity, businesses can adapt to fluctuations in demand, remaining competitive in the market. Agility is particularly crucial in industries with rapid product cycles, such as electronics and automotive.

Conclusion

In conclusion, turning to Mexico for industrial manufacturing offers a compelling solution for US companies seeking to optimize industrial manufacturing processes. With its proximity, cost-effectiveness, skilled workforce, and flexibility, Mexico has become an attractive destination for companies looking to streamline production and improve efficiency.

FAQs on Turning to Mexico for Industrial Manufacturing

1. What are the primary benefits of nearshoring to Mexico?

The primary benefits of nearshoring to Mexico include proximity, cost-effectiveness, skilled workforce, and flexibility.

2. How does nearshoring to Mexico impact transportation costs and lead times?

Nearshoring to Mexico significantly reduces transportation costs and lead times due to its proximity to the US, modernized ports, and efficient logistics.

3. What incentives does the Mexican government offer to attract foreign investment?

The Mexican government offers various incentives, including tax breaks, subsidies, and investment promotion programs, to attract foreign investment.

4. How does Mexico ensure quality control in manufacturing?

Mexico ensures quality control through robust measures, including ISO certifications, rigorous testing, and inspection procedures, to ensure products meet international standards.

5. What industries can benefit from nearshoring to Mexico?

Various industries can benefit from nearshoring to Mexico, including automotive, electronics, aerospace, and medical devices, among others.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.