Last Updated on September 30, 2024

If you're a business looking to expand and optimize manufacturing operations, you've likely heard of maquiladoras. These are specialized manufacturing facilities, primarily found in Mexico, that have become a popular choice for companies aiming to reduce costs and increase efficiency. In this article, we'll explore the pros and cons of Maquiladora operations. We'll help you make an informed decision about whether they are the right fit for your business.

Understanding Maquiladora Operations

What is a Maquiladora?

The term “Maquiladora” refers to a manufacturing solution created in the 1960s to take advantage of preferential tariff agreements between the U.S. and Mexico. It is also used to encourage foreign investment in that country. A maquiladora in Mexico is a factory or plant near the Mexico/U.S. border. It is staffed by Mexican workers, but owned and operated by a U.S. company (although other countries, such as China, can also run a maquiladora). A maquiladora allows manufacturers to operate duty-free and tariff-free. Businesses outsourcing their manufacturing needs can benefit from this approach in many ways. These needs may result from cost competitiveness or labor availability.

What is the difference between Maquiladora and IMMEX?

Maquiladoras and IMMEX are closely related concepts in Mexican manufacturing, but there is a key difference:

- Maquiladora: A physical factory in Mexico that assembles or manufactures goods for export, typically owned and operated by a foreign company. In essence, it is a building and a business.

- IMMEX: An acronym for "Industria Manufacturera, Maquiladora y de Servicios de Exportación" (Manufacturing, Maquiladora, and Export Services Industry). It's a government program established in Mexico to incentivize foreign companies to set up maquiladoras. The program offers duty exemptions and streamlines customs processes.

Here's an analogy: Think of IMMEX as a special club for maquiladoras. The club (IMMEX) offers benefits to its members (maquiladoras).

Over time, the terms became interchangeable. So, "maquiladora" is often used to refer to the broader IMMEX program. However, technically, a maquiladora is the factory, and IMMEX is the program it operates under.

The Pros of Maquiladora Operations

There are several pros and cons of Maquiladora operations. Let's begin with the advantages:

Cost Savings

This is a major draw. Maquiladoras benefit from lower labor costs in Mexico than many developed countries. Combine that with the tax incentives offered by the IMMEX program, and you can see a significant reduction in overall manufacturing expenses.

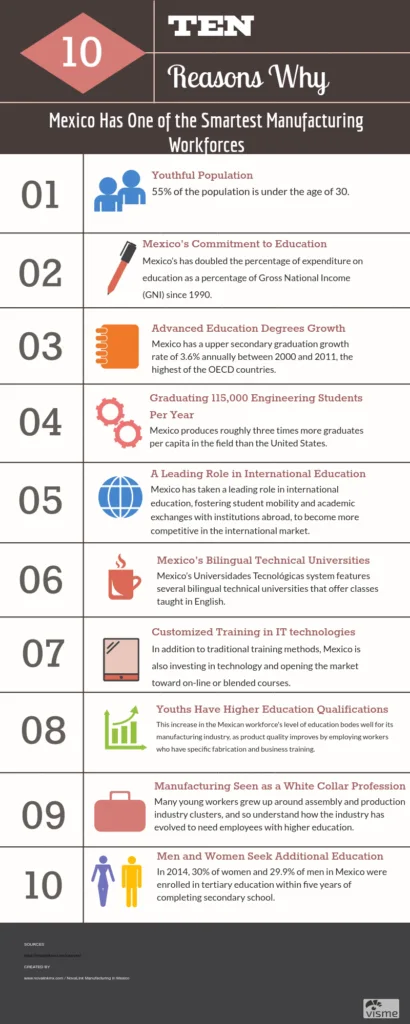

Skilled Workforce

Mexico has developed a skilled workforce over the years, making it an attractive location for manufacturing operations in various industries. The maquiladora industry itself has fostered development in this area, providing a ready talent pool for companies.

Proximity to the U.S. Market

For manufacturing companies targeting the U.S., maquiladoras offer a geographical advantage. Being located on the border streamlines transportation and logistics, leading to faster turnaround times and lower shipping costs.

Tax Benefits of Maquiladoras

Maquiladoras, operating under the IMMEX program, offer several tax benefits that significantly reduce manufacturing costs. Here are some key tax advantages.

- Value Added Tax (VAT) Exemptions: One of the biggest perks. Companies can import raw materials, machinery, and equipment duty-free, meaning they don't pay the 16% VAT typically applied to foreign goods. There are however, timeframes involved. Imported goods must be used for production and exported within a set period.

- Reduced Income Tax Rates: Mexico may offer income tax rates lower than in the company's home country. This can lead to substantial savings on maquiladora profits.

- Duty-Free Exports: Finished goods produced in the maquiladora can be exported duty-free to certain countries, particularly the U.S. and Canada under NAFTA (now USMCA). This eliminates tariffs that would otherwise increase the price of goods in the destination country.

- Lower Property Taxes: Generally, property taxes are lower in Mexico compared to many developed countries. This translates to additional cost savings for companies establishing maquiladora facilities.

By taking advantage of these tax benefits, maquiladoras can become very competitive in overall production costs. It's imperative to note that specific tax regulations can be complex, so consulting with a professional versed in Mexican tax law is recommended.

What is the main purpose of maquiladoras entities? The answer is simple; to not pay taxes. While that does sound appealing, bear in mind that it is necessary to have the right plan and strategy in place in order to obtain this fiscal “paradise”. The government allows for maquiladoras as long as they accomplish everything within the legal guidelines stated for such purposes. Therefore, in this article we briefly provide general considerations and ideas in the utilization of maquiladoras as a great opportunity to create profitable businesses in Mexico.

Braumiller Law Group

What Industries Are the Best Fits for Maquiladoras?

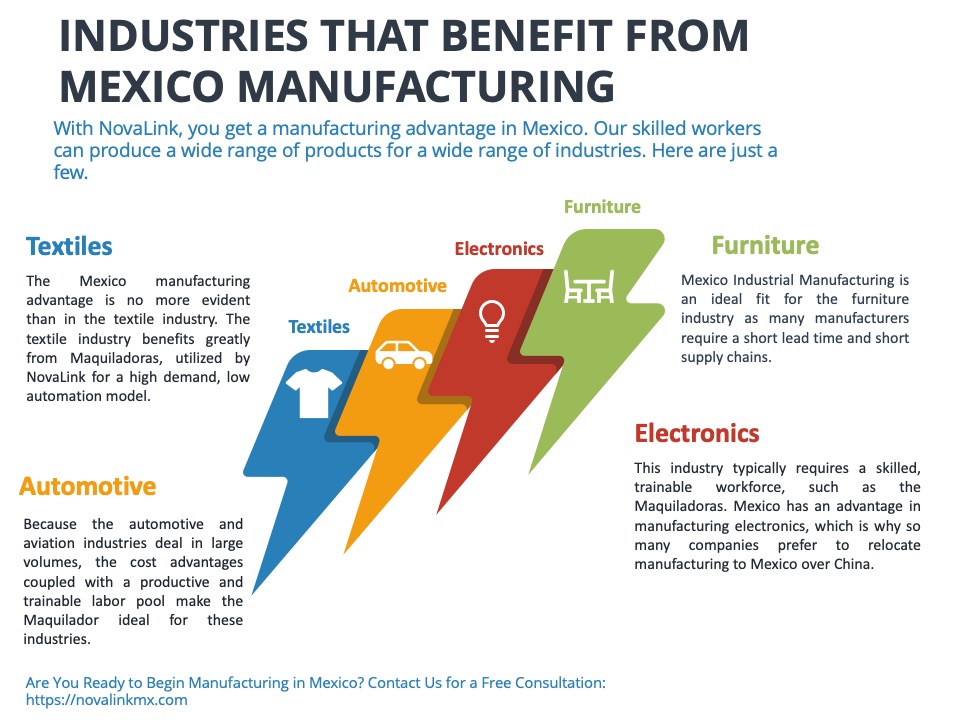

Maquiladoras are a good fit for industries that can benefit from their specific advantages. Here are some of the industries that tend to thrive in maquiladoras:

- Electronics: This is a major industry sector for maquiladoras. Components and parts can be imported duty-free, assembled in Mexico, and then exported duty-free to the U.S. under USMCA, making it cost-competitive.

- Automotive: Similar to electronics, the proximity to the U.S. market and duty-free benefits on parts and finished vehicles make maquiladoras attractive for auto manufacturers.

- Medical Devices: Mexico has a growing medical device industry with a presence in maquiladoras. Skilled labor and potentially lower production costs compared to the U.S. can be a big advantage.

- Aerospace: The Mexican aerospace industry is on the rise, and maquiladoras play a role. Certain parts and components can be manufactured in Mexico and then exported for final assembly elsewhere.

- Appliances: Maquiladoras are suitable for assembling various appliances due to the availability of a skilled workforce and the potential for cost savings.

- Textiles and Apparel: While this industry has moved away from some developed countries due to rising costs, maquiladoras can offer competitive production costs for apparel and textiles.

- Toys and Games: Another industry that can benefit from the combination of a skilled workforce and potential cost reductions through maquiladoras.pen_spark

The Cons of Maquiladora Operations

While maquiladoras offer many advantages, there are also potential drawbacks to consider. Here are some of the key cons of maquiladora operations:

- Legal Complexity: Navigating the legal frameworks and regulations associated with Maquiladoras can be complex and require expert guidance.

- Supply Chain Risks: Maquiladoras and their dependence on cross-border supply chains can expose businesses to geopolitical instability and transportation disruptions.

- Labor Union Issues: Labor unions are prevalent in Mexico, and disputes can lead to strikes, affecting production schedules and business operations.

- Environmental Concerns: Some Maquiladora facilities have been criticized for their environmental practices, which may affect a company's reputation.

- Currency Exchange Risks: Fluctuations in currency exchange rates can impact Maquiladora profitability, creating financial uncertainty.

Conclusion

In conclusion, there are many pros and cons of Maquiladora operations, including cost savings, a skilled workforce, and proximity to the U.S. market. However, they come with challenges such as legal complexities, supply chain risks, labor union issues, environmental concerns, and currency exchange risks. Before establishing Maquiladora operations, it's essential for businesses to carefully weigh the pros and cons. They should consider their specific needs, and develop a robust strategy to navigate the potential obstacles.

FAQs

1. What types of businesses are best suited for Maquiladora operations?

Maquiladoras are ideal for businesses in manufacturing-intensive industries, such as electronics, automotive, aerospace, and textiles.

2. How can a company navigate the legal complexities of Maquiladora operations?

Seeking legal counsel and working with experts who understand the intricacies of Mexican regulations is advisable.

3. Are there ways to mitigate supply chain risks in Maquiladora operations?

Diversifying suppliers, having contingency plans, and monitoring geopolitical situations can help reduce supply chain risks.

4. What environmental practices should businesses consider in Maquiladora operations?

Adopting sustainable and environmentally-friendly practices can improve a company's image and reduce the risk of environmental concerns.

5. How can a company manage currency exchange risks in Maquiladora operations?

Hedging strategies and financial planning can help mitigate the impact of currency exchange fluctuations on profitability.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.

Explore More: Discover Related Blog Posts

Expand your knowledge and delve deeper into Maquiladoras in Mexico with our curated collection of related blog posts.

- What Type of Company Should Not Move to Mexico?

- Mexico’s Manufacturing Workforce in 2025: A Game-Changer for Global Industry

- How to Find the Best Maquiladora for Your Manufacturing Needs

- Strategic Measures to Fortify Mexico’s Textile Industry Under President Claudia Sheinbaum

- Labor vs. Land: What Costs More in Mexican Manufacturing?