Last Updated on October 31, 2024

In an era defined by global economies, companies seek strategic advantages to stay competitive in the dynamic marketplace. One notable trend shaping manufacturing is the increasing preference for Mexico as a pivotal hub for production and assembly. Mexico's allure as a manufacturing hub has captured the attention of businesses worldwide, prompting a fundamental shift in sourcing and production strategies.

Join us on this exploration as we uncover the economic prowess, cost-efficiency, strategic location, trade advantages, and technological advancements that collectively contribute to Mexico's emergence as a manufacturing hub.

Economic Stability: The Foundation of Growth

One of the primary drivers behind companies choosing Mexico as their manufacturing hub is robust economic stability. With steady GDP growth and business-friendly economic policies, Mexico provides a secure foundation for companies seeking long-term success in manufacturing endeavors.

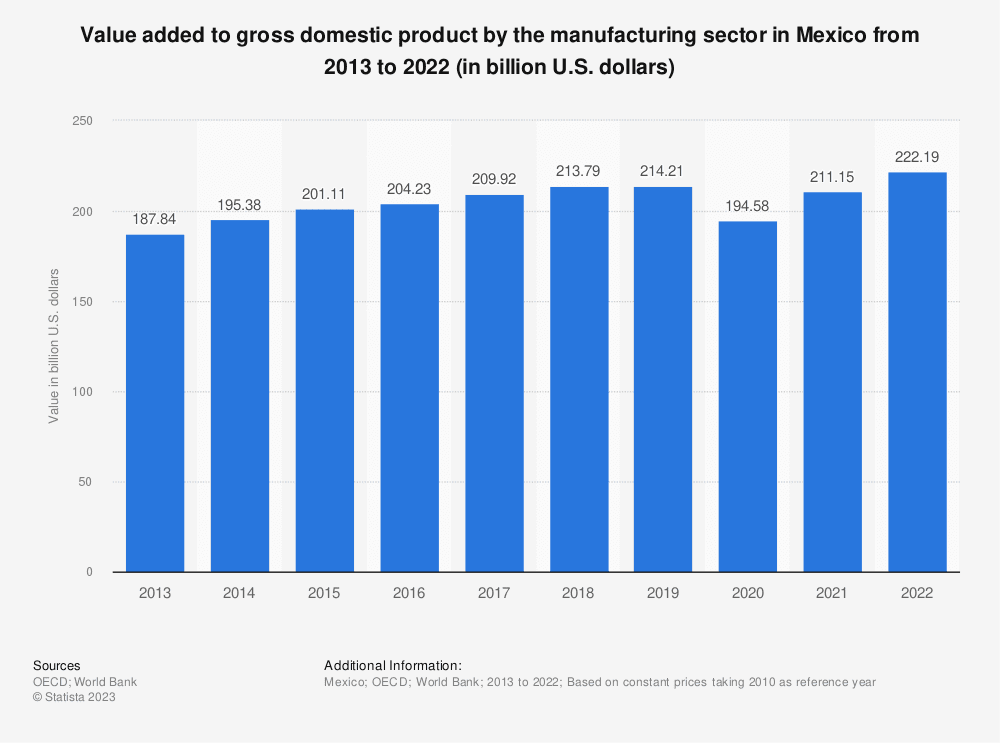

Steady GDP Growth

Mexico's consistent and steady Gross Domestic Product (GDP) growth over the years creates a favorable environment for businesses looking to establish or expand manufacturing operations. GDP growth stability serves as an indicator of a resilient and thriving economy, providing companies with confidence in their decision to invest in Mexico. Predictability is particularly vital for long-term planning, helping businesses navigate uncertainties and make informed decisions.

Steady GDP growth also reflects Mexico's resilience in the face of global economic challenges. This stability creates a reliable backdrop for companies, offering them a secure platform to build and grow their manufacturing operations. This is without the heightened risks associated with volatile economic conditions.

Mexico’s real GDP grew at a revised annualized 3.4 percent in the second quarter, about the same as the previous quarter’s gains of 3.3 percent. This is the seventh consecutive quarter the Mexican economy has expanded, and growth is generally surprising to the upside.

Federal Reserve Bank of Dallas

Business-Friendly Economic Policies

Mexico's commitment to creating a business-friendly environment is another key factor that attracts companies to establish manufacturing hubs within its borders. The country has implemented a range of policies designed to encourage foreign investment and foster a conducive atmosphere for businesses.

The simplification of bureaucratic processes, the reduction of regulatory hurdles, and the introduction of incentives for foreign businesses all contribute to Mexico's reputation as a welcoming destination for manufacturing ventures. The government's proactive stance on creating an environment that supports business growth is a testament to its commitment to positioning Mexico as a competitive player in the global manufacturing landscape.

Security for Long-Term Success

For companies eyeing Mexico as a manufacturing hub, the combination of steady GDP growth and business-friendly economic policies provides a secure foundation. Stability in economic conditions allows businesses to make strategic decisions with confidence, fostering an environment where long-term success becomes a tangible possibility.

In this stable economic context, companies can plan for the future, make investments with a reasonable expectation of returns, and navigate market dynamics with predictability. This sense of security is invaluable for businesses operating in a globalized and competitive market, where uncertainties can significantly impact operational efficiency and profitability.

Cost-Efficiency and Skilled Labor: The Winning Combination

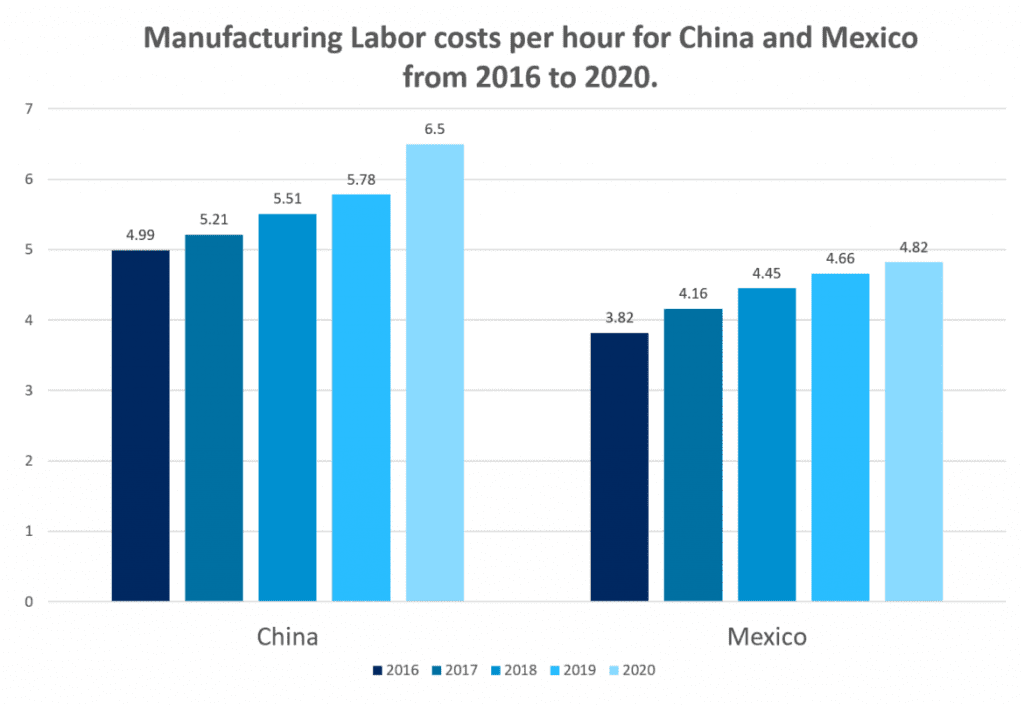

Mexico stands out for cost-effectiveness without compromising quality. Companies leverage the unique combination of skilled labor and competitive costs, making it an attractive proposition for manufacturing operations. This dual advantage allows businesses to maintain high-quality production while optimizing operational expenses.

Balancing Act: Cost-Effectiveness and Quality

Mexico's appeal lies in its ability to strike a delicate balance between cost-effectiveness and high-quality production. Unlike the common trade-off between cutting costs and maintaining quality, Mexico offers a harmonious fusion of both elements. This has proven to be a game-changer for companies seeking manufacturing solutions that don't compromise on excellence.

Skilled Labor Force: A Strategic Asset

Central to Mexico's competitive edge is its skilled labor force. The country has invested significantly in education and skill development, creating a workforce that is proficient and adaptable to evolving industry demands. Companies benefit from a pool of skilled workers capable of handling intricate manufacturing processes with precision.

Skilled labor is a strategic asset that enables businesses to uphold stringent quality standards. Whether in automotive manufacturing, electronics, or aerospace, Mexico's workforce demonstrates a level of proficiency that aligns with high expectations of industries demanding precision and expertise.

Competitive Costs: Maximizing Efficiency

Mexico offers competitive manufacturing costs, providing companies with a strategic advantage in optimizing operational expenses. This is not merely about low wages but involves a holistic view of business costs. From real estate and utilities to overall operational efficiency, Mexico presents a favorable cost structure for businesses.

Competitive costs extend beyond labor to encompass various aspects of manufacturing, allowing companies to allocate resources effectively and achieve a higher return on investment. Financial efficiency is a key factor in decision-making for companies looking to establish or expand manufacturing operations.

Dual Advantage: High-Quality Production and Operational Optimization

The synergy between skilled labor and competitive costs in Mexico allows businesses to achieve a dual advantage. Companies can maintain high-quality production standards that meet or exceed global benchmarks while optimizing operational expenses. This dual advantage enhances competitiveness in the global marketplace.

Businesses operating in Mexico find that they don't need to compromise on quality to achieve cost-effectiveness, nor inflate their operational budget to maintain high standards. This balance contributes to manufacturing operations' overall efficiency, creating a win-win scenario for companies seeking excellence without breaking the bank.

Outsourcing in Mexico offers a wealth of benefits for businesses seeking cost-effective solutions and access to a skilled workforce. By understanding the salary landscape, focusing on effective communication and collaboration, and utilizing time management tools like Insightful, you can unlock the full potential of outsourcing in Mexico and ensure the success of your remote team.

Unlock the Benefits of Outsourcing to Mexico: A Comprehensive Guide

Proximity to Major Markets: A Strategic Location

Mexico's geographical proximity to major markets, especially the United States, is a strategic advantage that companies can't afford to overlook. This section explores how Mexico's location reduces shipping costs, shortens transit times, and facilitates just-in-time manufacturing, all contributing to enhanced competitiveness for Mexico as a manufacturing hub.

Reduced Shipping Costs: An Economic Boon

When transporting goods across borders, every mile matters. Mexico's close proximity to the United States translates into reduced shipping costs for companies. The shorter distance between manufacturing facilities in Mexico and consumer markets in the U.S. leads to lower transportation expenses, allowing businesses to allocate resources more efficiently.

Reduced shipping costs are not just about immediate financial savings; they also contribute to a more sustainable and environmentally friendly supply chain. By minimizing the distance traveled, companies in Mexico can lower their carbon footprint, aligning with the growing emphasis on eco-friendly business practices.

Shortening Transit Times: Speeding Up Operations

In manufacturing, time is critical. Mexico's proximity accelerates transit times, ensuring that products reach their destination swiftly. This is especially true in industries where time-to-market is a competitive advantage.

Shortened transit times enable companies to respond rapidly to market demands, reduce lead times, and maintain agile manufacturing operations. Whether it's raw materials or finished goods, reduced transit times enhance businesses' competitiveness.

Facilitating Just-in-Time Manufacturing: Precision and Efficiency

Just-in-time (JIT) manufacturing is a methodology where goods are produced only as needed, minimizing inventory costs. Mexico's strategic location supports JIT manufacturing by facilitating quick and reliable transportation. Companies can maintain lean inventories, reduce storage costs, and respond promptly to demand fluctuations.

JIT practices contribute to operational efficiency and cost-effectiveness, providing a competitive advantage in industries where agility and adaptability are paramount.

Trade Agreements and Tariff Benefits: A Business-Friendly Environment

Navigating the global trade landscape can be complex, but Mexico's extensive network of trade agreements simplifies the process for businesses. This section delves into how these agreements provide companies with tariff benefits, reducing costs and fostering a more competitive environment.

Trade Agreements: Mexico's Global Connectivity

Mexico's commitment to international trade is underscored by its vast web of trade agreements, positioning the country as a hub for global connectivity. These agreements span regions and nations, creating a framework that facilitates goods and services flow across borders.

Tariff Benefits: A Competitive Edge

One of the most tangible advantages of Mexico's trade agreements is tariff benefits. Tariffs, or taxes on imported and exported goods, can significantly impact cross-border companies' cost structure. Mexico's trade agreements mitigate these costs, providing businesses with a competitive edge.

By reducing or eliminating tariffs on certain goods, these agreements create a level playing field for companies operating in Mexico. This reduction in tariffs directly translates into cost savings, allowing businesses to allocate resources more efficiently and competitively price their products on the global market.

Fostering a Competitive Environment

Tariff benefits ripple beyond individual companies. Collective trade barriers reduction fosters a more competitive environment on a broader scale. As businesses within Mexico enjoy cost advantages, they can position themselves as attractive partners for international collaborations and supply chain integration.

This heightened competitiveness contributes to Mexico's appeal as a manufacturing hub. It attracts companies that seek a streamlined trade process but also a strategic advantage on the global market.

Diversification and Market Access

Mexico's trade agreements simplify trade processes and open doors to diverse markets. Businesses operating within the country gain access to a wide array of international markets with reduced trade barriers. This enables them to diversify their customer base and explore new business opportunities.

For industries with global ambitions, the ability to tap into multiple markets through established trade agreements positions Mexico as a central player in the global supply chain. This diversification acts as a risk mitigation strategy, particularly in times of economic uncertainty or geopolitical shifts.

For U.S. exporters, Mexico’s trade liberalization efforts mean that the Mexican market is one of the most open and competitive in the world.

The United States, Mexico, and Canada are parties to the United States-Mexico-Canada Agreement (USMCA), which entered into force on July 1, 2020, replacing the North American Free Trade Agreement (NAFTA). Qualifying goods and services that had zero tariffs under NAFTA will remain at zero under USMCA.

International Trade Administration

Infrastructure and Technology: A Pillar of Operational Efficiency

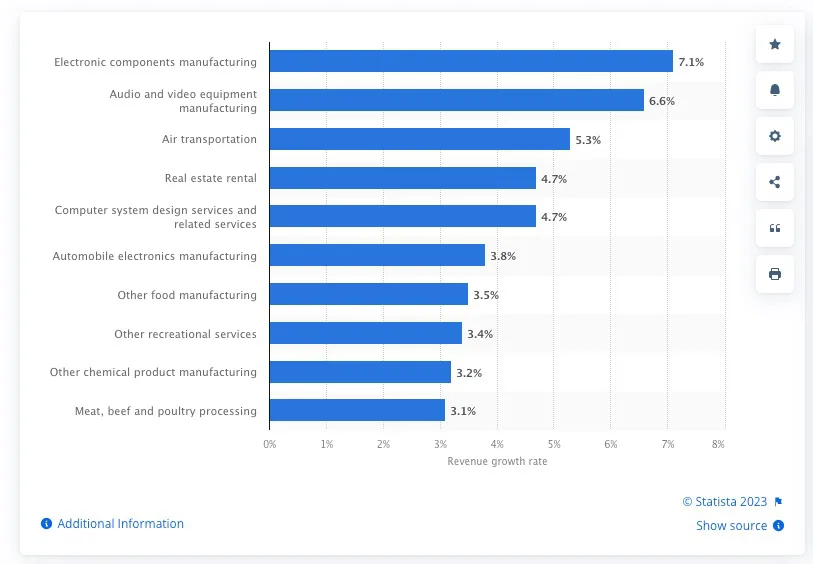

Modern infrastructure and technological advancements make Mexico an attractive manufacturing hub. Companies benefit from state-of-the-art facilities and capabilities, positioning Mexico as a hub for innovation and excellence in manufacturing.

State-of-the-Art Infrastructure: Building Success Foundations

Mexico's commitment to becoming a manufacturing hub is palpable in its investments in modern infrastructure. The country boasts a robust network of roads, railways, ports, and airports, creating a seamless transportation system that facilitates efficient goods movement. These modern transportation links connect manufacturing facilities within Mexico but also provide a gateway to global markets.

Beyond transportation, Mexico's infrastructure extends to industrial parks and zones specifically designed for manufacturing needs. These zones offer companies purpose-built facilities, often equipped with utilities and services, providing a turnkey solution for businesses looking to establish a manufacturing presence. This state-of-the-art infrastructure serves as the foundation for manufacturing success.

To make investing in Mexico more lucrative, the Mexican government has developed its infrastructure with a particular focus on the transportation, telecom, and energy sectors. There is also a heavy emphasis on resource extraction such as oil. In recent years, there has been a lot of IT investment, in terms of education, training and tax breaks for startups.

The Benefits of Outsourcing to Mexico

Technological Advancements: Catalysts for Innovation

In addition to a robust infrastructure, Mexico has embraced technological advancements as catalysts for innovation. Manufacturing processes today depend on automation, data analytics, and connectivity. Mexico has not only kept pace with these advancements but actively embraced them to enhance operational efficiency and product quality.

Manufacturing facilities in Mexico are equipped with cutting-edge technologies such as robotics, artificial intelligence, and the Internet of Things (IoT). These technologies streamline production processes, reduce lead times, and enhance precision. Companies operating in Mexico can leverage these tools to stay at the forefront of innovation, meeting the demands of industries that require high-tech manufacturing capabilities.

Positioning Mexico as a Hub for Excellence

The synergy between modern infrastructure and technological advancements positions Mexico as a hub for manufacturing excellence. Companies benefit from an ecosystem that fosters innovation, allowing them to push the boundaries of product development, efficiency, and sustainability.

This positioning is particularly appealing to industries that require precision and customization. From automotive and aerospace to electronics and medical devices, Mexico's manufacturing capabilities span a diverse range of sectors. Each sector benefits from state-of-the-art facilities and cutting-edge technologies.

Statistia: Fastest growing industries by revenue growth in Mexico between 2019 and 2020

Global Competitiveness and Foreign Investment Attraction

Modern infrastructure and technological advancements contribute to Mexico's global competitiveness. As companies worldwide seek locations that offer efficiency, innovation, and cost-effectiveness, Mexico emerges as a top choice. This attractiveness has led to a surge in foreign direct investment, further fueling the manufacturing sector.

Foreign companies looking to establish a manufacturing presence will find in Mexico not just a location but a partner in progress. Modern infrastructure and technological capabilities are compelling incentives for businesses seeking a competitive edge in the global market.

Mexico attracts the most FDI in Central and South America:

Mexico: Foreign investment

- In addition to being very open to foreign direct investment, the country is very well integrated into the world economic order: it is a member of USMCA, OECD, G20 and the Pacific Alliance.

- It enjoys a strategic geographic location and acts as a transit platform to North America and Latin America.

- The country has a wide variety of natural resources, which allows the development of all types of industries at very competitive prices.

- The cost of labour (a young and abundant labour force) is not very high and is relatively well qualified.

- The country is the seventh biggest tourist destination in the world and has in parallel a large and important industrial base.

Challenges and Solutions: Navigating the Terrain

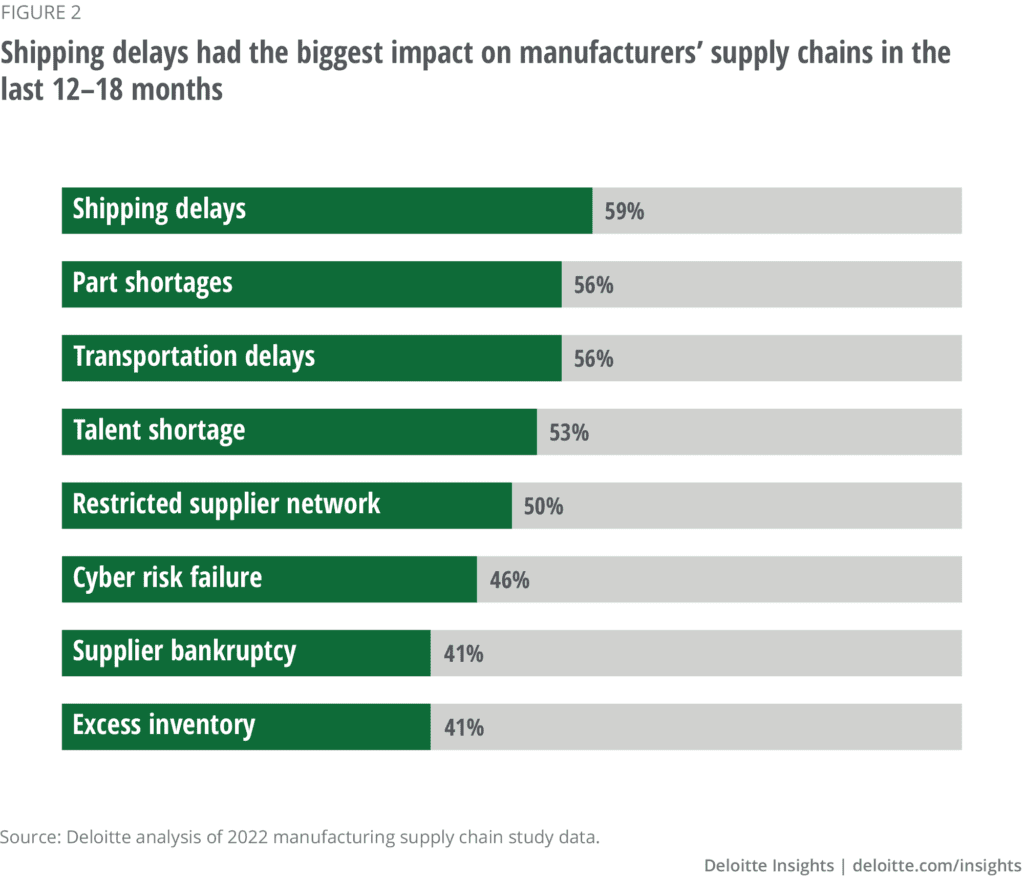

No strategic move comes without challenges. This section explores potential hurdles in manufacturing in Mexico and provides insights into strategies and solutions businesses employ to overcome them.

Potential Hurdles in Manufacturing in Mexico:

- Cultural Differences: Operating in an unfamiliar cultural context can pose initial challenges. Language barriers, varying business etiquette, and differences in work cultures may require adaptation for seamless operations.

- Logistical Complexities: While Mexico's proximity to major markets is an advantage, navigating complex logistics, particularly across the U.S.-Mexico border, can present challenges related to customs, transportation delays, and regulatory compliance.

- Legal and Regulatory Landscape: Adhering to Mexican laws and regulatory requirements demands thorough understanding and compliance. Different standards and regulations may pose complexities for companies unfamiliar with the local legal landscape.

- Skilled Labor Shortages: While Mexico has a skilled workforce, specific industries may face talent shortages. Companies may need to implement strategic workforce development initiatives or leverage training programs to address these shortages.

- Security Concerns: Certain regions in Mexico may have security concerns that businesses need to address. Implementing robust security measures and staying informed about the local context are crucial for mitigating potential risks.

Strategies and Solutions:

- Cross-cultural Training: To overcome societal differences, companies often invest in cross-cultural training for their employees. This includes language programs, multicultural sensitivity training, and team-building exercises to foster effective communication and collaboration.

- Efficient logistics management: Businesses employ advanced logistics management systems to address transportation complexities. Utilizing technology for real-time tracking, maintaining open communication with logistics partners, and proactive risk management streamlines the supply chain.

- Legal Consulting and Compliance Teams: Engaging legal experts and compliance teams familiar with the Mexican regulatory landscape is proactive. Regular legal consultations and compliance teams ensure businesses stay abreast of regulatory changes and adhere to local standards.

- Strategic Workforce Planning: To tackle skilled labor shortages, companies implement strategic workforce planning initiatives. This includes partnering with local educational institutions, offering specialized training programs, and collaborating with government initiatives to foster skill development.

- Security Measures and Risk Assessments: Mitigating security concerns involves thorough risk assessments. Implementing security measures such as surveillance systems, secure transportation practices, and collaboration with local law enforcement are essential components of a comprehensive security strategy.

Future Trends and Opportunities: A Glimpse into Tomorrow

Looking towards the future, this section examines emerging trends in Mexico's manufacturing landscape. By analyzing potential opportunities and developments, businesses can position themselves strategically to harness the evolving dynamics of the Mexican manufacturing sector.

Industry 4.0 integration

The fourth industrial revolution, often referred to as Industry 4.0, is characterized by the integration of digital technologies into manufacturing processes. In Mexico, there is a growing trend towards smart manufacturing practices, including automation, artificial intelligence, and the Internet of Things (IoT). Businesses that invest in Industry 4.0 technologies can enhance efficiency, reduce costs, and stay competitive in the evolving global market.

Industry 4.0 in Mexico is a phenomenon that has gained strength in recent years. With the arrival of nearshoring, economic growth has been driven toward digital transformation and the adoption of advanced technologies.

I4.0's own technology has been widely adopted in the automotive sector, especially compared to other sectors. Companies like Audi, BMW and General Motors have invested in the creation of highly automated production plants in the country. These plants employ cutting-edge technologies, such as collaborative robotics and artificial intelligence, allowing companies to improve the efficiency and quality of their products.

Mexico's Industry 4.0 Revolution: Challenges and Opportunities

Sustainability and green manufacturing

Environmental sustainability is becoming an increasingly significant consideration in manufacturing. Mexico is witnessing a shift towards green manufacturing practices, driven by global environmental concerns and consumer demand for eco-friendly products. Businesses that embrace sustainable practices, such as renewable energy adoption, waste reduction, and responsible sourcing, can contribute to resource conservation. However, they also appeal to a growing market of eco-conscious consumers.

Resilience and Supply Chain Diversification

Recent global disruptions underscore the importance of resilient supply chains. There is a trend towards diversifying supply chains to mitigate risks associated with geopolitical tensions, natural disasters, or other unforeseen events. Mexico's strategic location and comprehensive trade agreements make it an attractive option for businesses seeking to diversify their supply chains and enhance their resilience.

Advanced Materials and Manufacturing Techniques

Innovation in materials and manufacturing techniques is a key driver of competitiveness. Mexico is witnessing a trend towards advanced materials, such as composites and high-performance alloys, to enhance product quality and durability. Additionally, advancements in additive manufacturing (3D printing) are opening new possibilities for rapid prototyping and customized production.

Collaboration in research and development

To stay at the forefront of technological advancements, businesses engage in collaborative research and development (R&D) initiatives. Partnerships between businesses, research institutions, and government bodies in Mexico can foster innovation and drive cutting-edge technologies. Companies that actively participate in collaborative R&D efforts position themselves as leaders in their respective industries.

Digital Transformation in Supply Chain Management

Digital supply chain management is a transformative trend in Mexico's manufacturing sector. Integration of digital platforms for real-time tracking, demand forecasting, and inventory management is gaining prominence. Businesses that embrace digital supply chain solutions can optimize operations, reduce lead times, and enhance overall supply chain efficiency.

Conclusion: A Transformative Choice for Global Competitiveness

In conclusion, the factors that make Mexico manufacturing hub attractive are multi-faceted. From economic stability and cost-efficiency to strategic location and technological advancements, the decision to establish a manufacturing presence in Mexico is a transformative one. As businesses continue to evolve in an interconnected world, Mexico emerges as a beacon, offering a pathway for companies to unlock unparalleled competitive advantages in their manufacturing endeavors.

FAQs: Unveiling More Insights

Q1. Why is Mexico becoming a preferred manufacturing hub?

A1. Mexico's economic stability, cost-effective skilled labor, strategic location, and trade agreements make it an ideal choice for companies seeking a competitive edge.

Q2. How does Mexico's proximity to major markets benefit businesses?

A2. Mexico's geographical proximity, particularly to the United States, reduces shipping costs, shortens transit times, and facilitates just-in-time manufacturing, enhancing overall competitiveness.

Q3. What role do trade agreements play in Mexico's appeal as a manufacturing hub?

A3. Mexico's extensive network of trade agreements provides businesses with tariff benefits, reducing costs and fostering a more business-friendly environment.

Q4. How do companies navigate challenges in manufacturing in Mexico?

A4. Businesses address challenges through strategic solutions, often learning from real-world examples and best practices to ensure a smooth manufacturing operation.

Q5. What does the future hold for manufacturing in Mexico?

A5. Emerging trends suggest continued growth and opportunities in Mexico's manufacturing sector, offering businesses a glimpse into the potential for future success.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.